Information on textile straightening systems

- Description

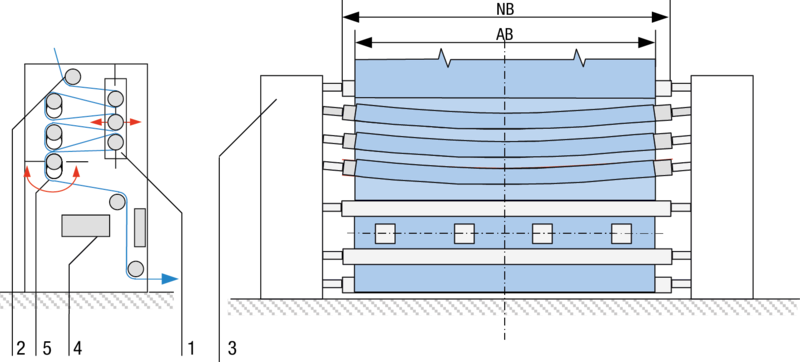

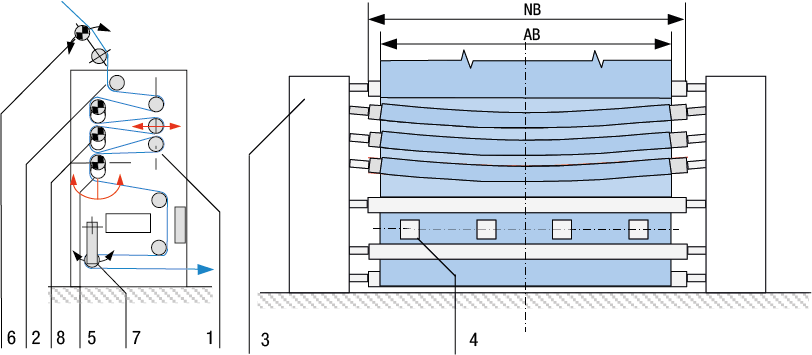

- Function drawing

Function

The sensor system continuously detects warping at predefined positions across the web. The evaluation logic decides whether skewing or bowing is present. The position controller compares the actual value of the warping with the target value and controls the actuators for skewing and bowing.

Area of use

Textile production systems, such as the infeed of stenters and leveling frames, decatizing systems, the infeed of printing machines, flame lamination systems and coating systems.

Application

As a general rule, the straightening system should always be installed immediately before the process. Woven and knitted fabrics must always be fed centrally into the straightening system with sufficiently consistent tension. With knitted fabrics, a spreading device must also be provided.

Woven fabric

Knitted fabric

Legend

AB = Operating width | NB = Nominal width | 1 = Skew adjustment | 2 = Infeed roller | 3 = Weft aligner | 4 = Sensor | 5 = Bow adjustment | 6 = Spreading device | 7 = Dancer roller controller | 8 = Additional drive