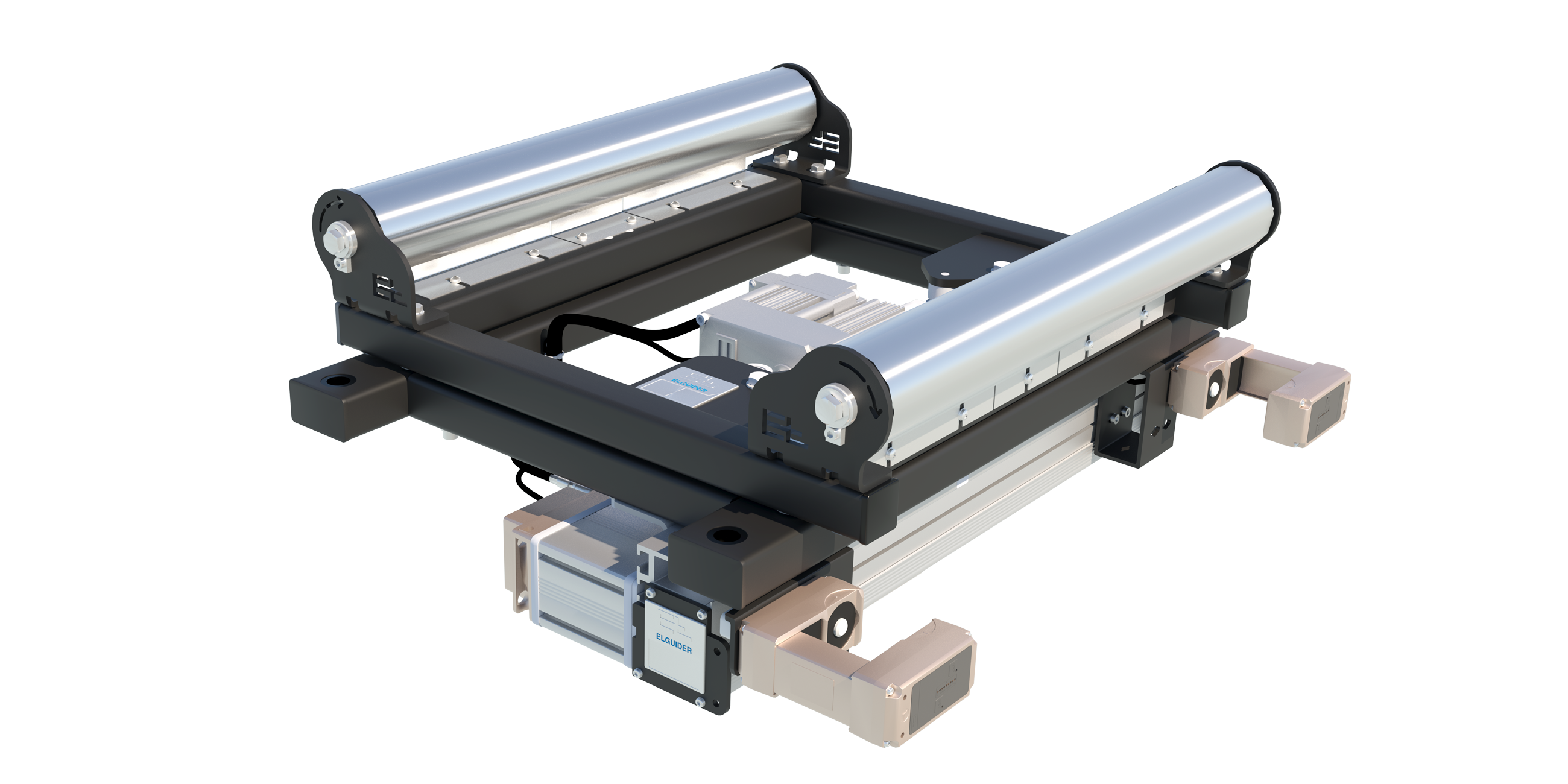

The central challenge for the bag making machine is the processing of different substrates from reels. In the production process, this can result in a large dynamic infeed error after unwinding and difficult scanning of the guiding criterion in stop-and-go operation. Erhardt+Leimer offers convincing solutions for this area. Our winding station control offers high control dynamics, even at high production speeds. The use of our new AD11 is particularly advantageous here, it can be straightforwardly integrated into the machine control system via fieldbus. Other components and systems can be connected to a network and integrated thanks to our new EL.NET technology.