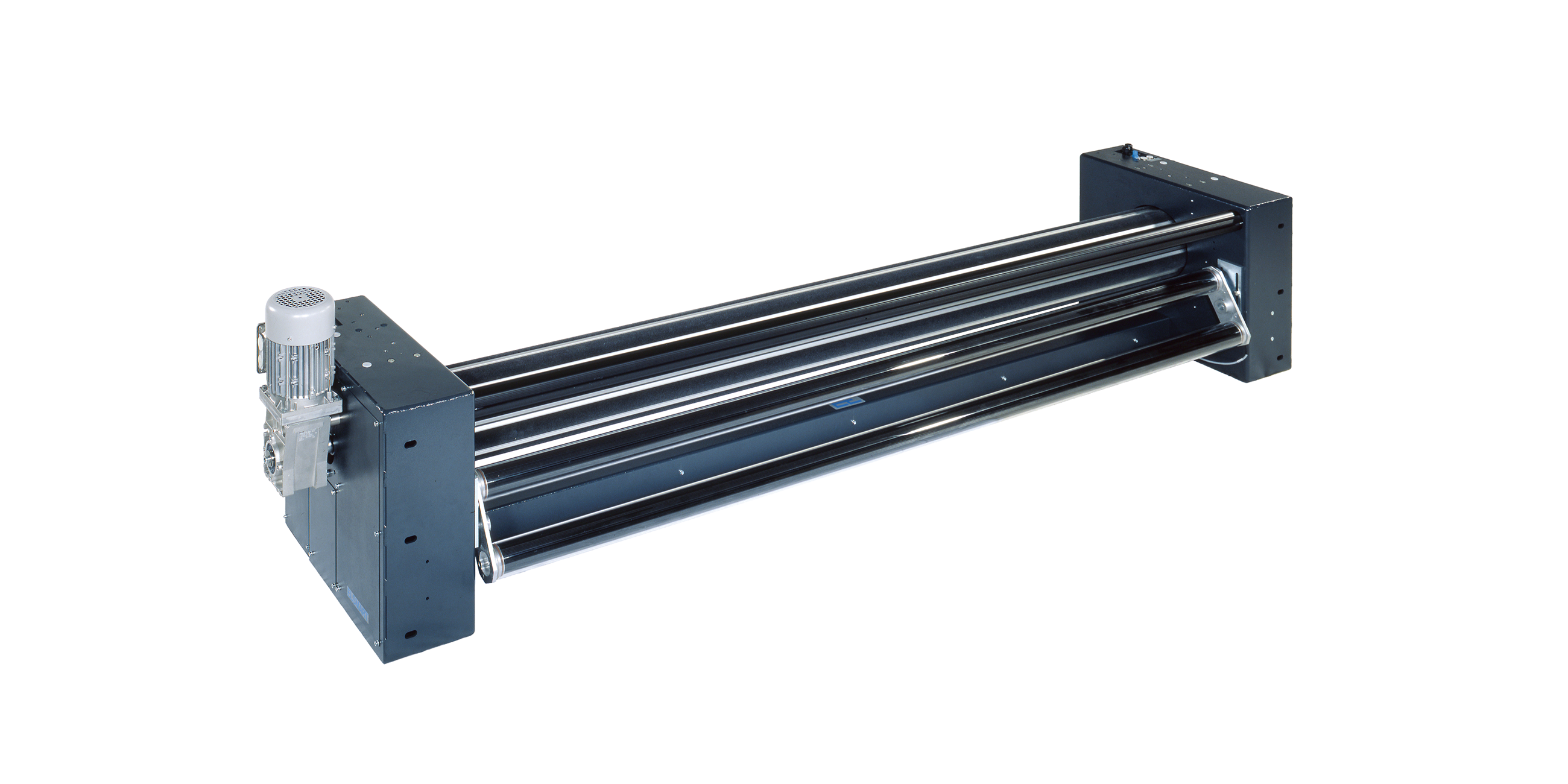

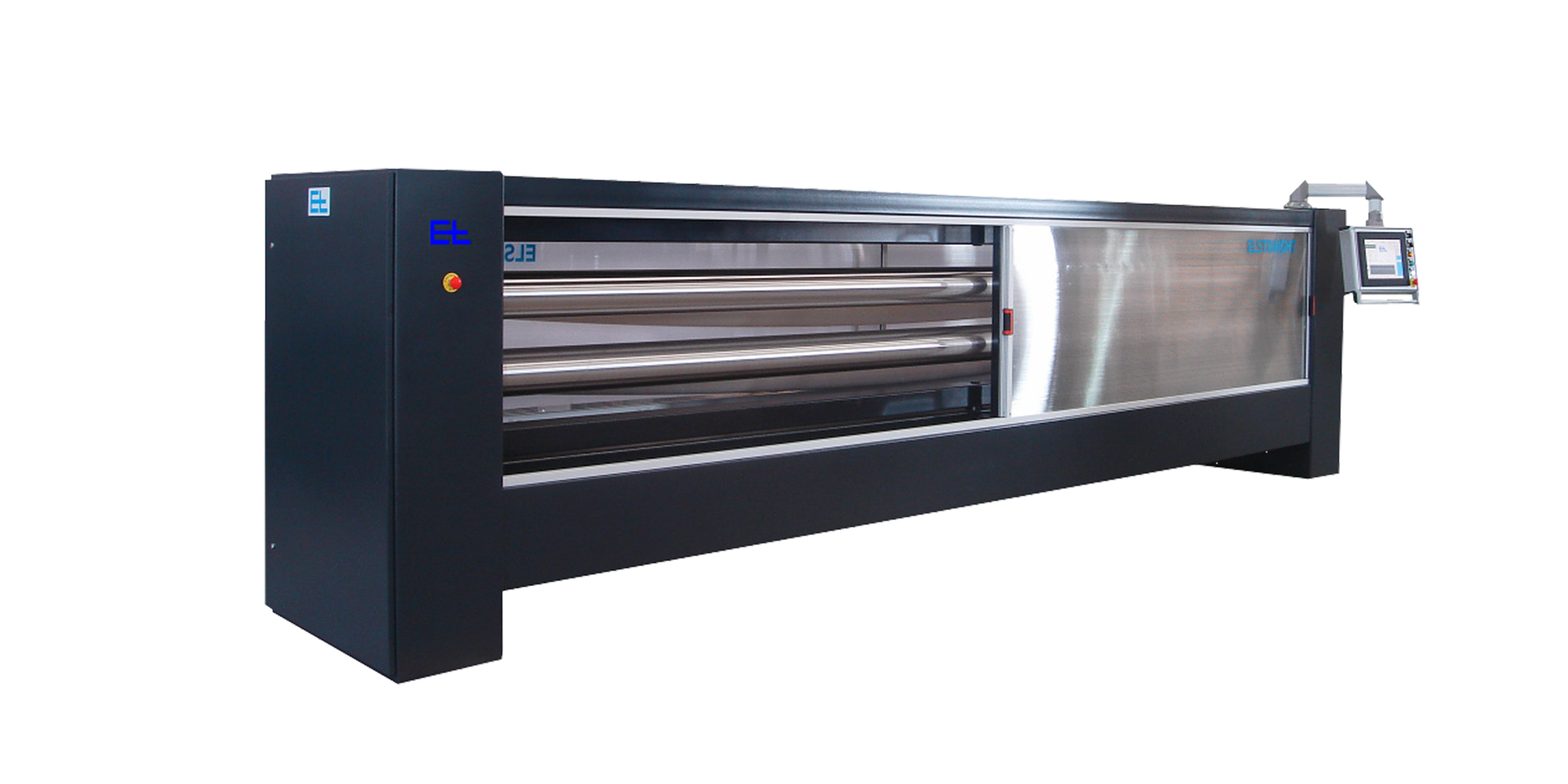

These days, a modern printing machine includes precise web guiding and printing belt control. The web guiding should transfer the web to the printing belt quickly and precisely. The most important requirement during the professional printing of knitted fabrics is an optimal web tension.

Particularly with highly elastic knitted fabrics, several web tension controls may be used in the infeed. Furthermore, a web width control can help with the correctly positioned transfer of the web to the printing belt with the required width without creases, but with completely spread edges. Optionally, web cleaning can always be very useful.