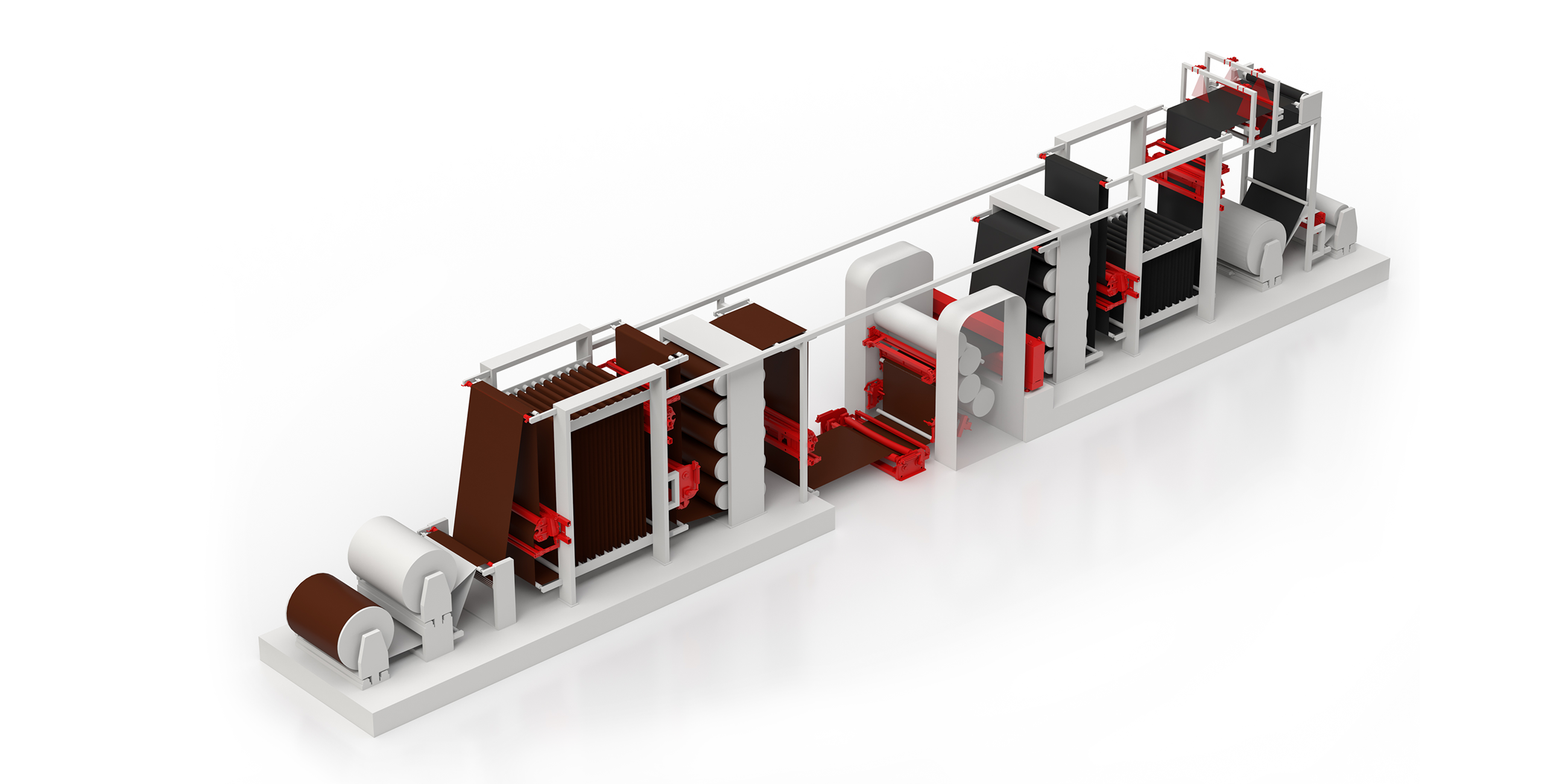

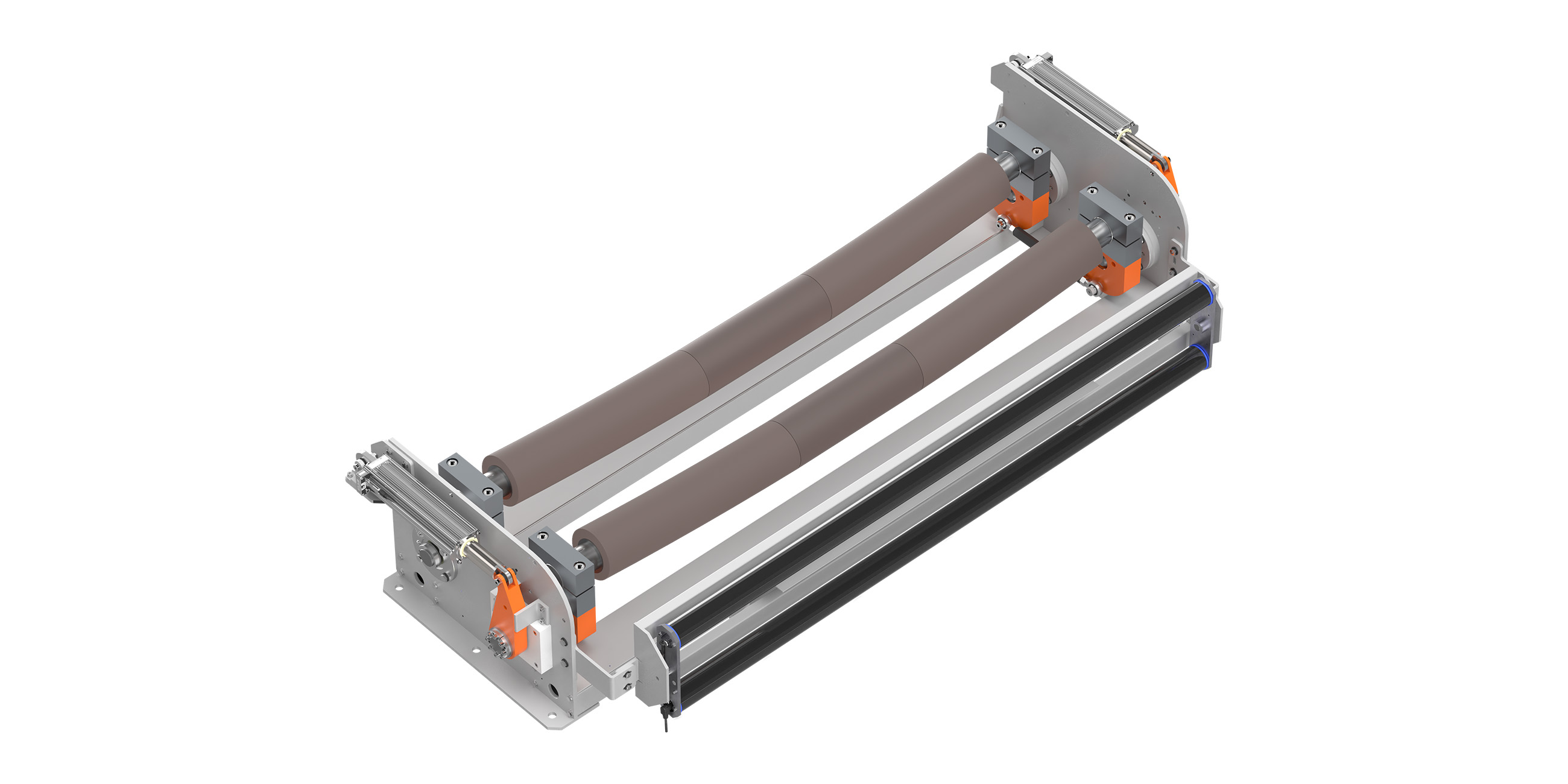

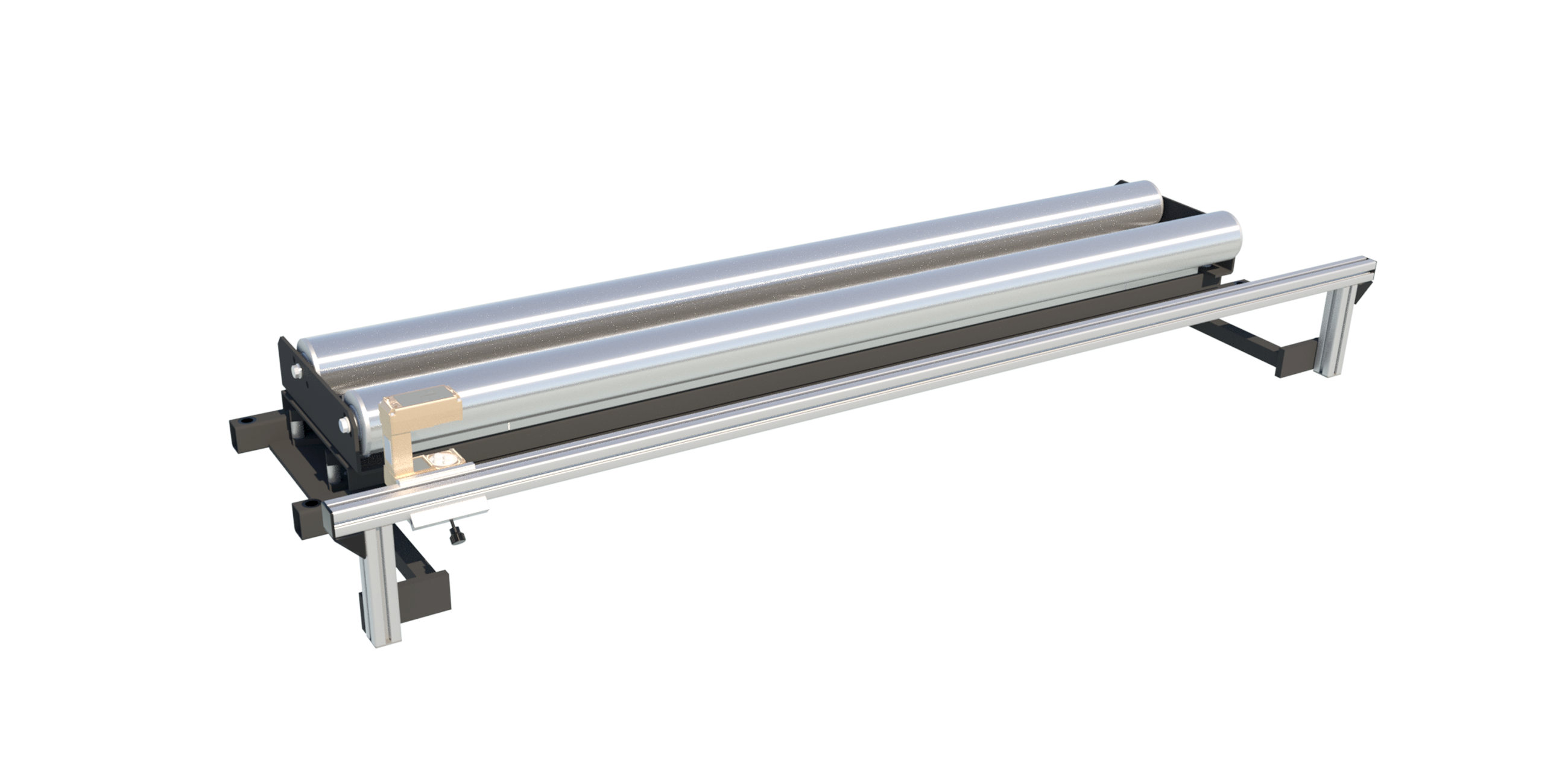

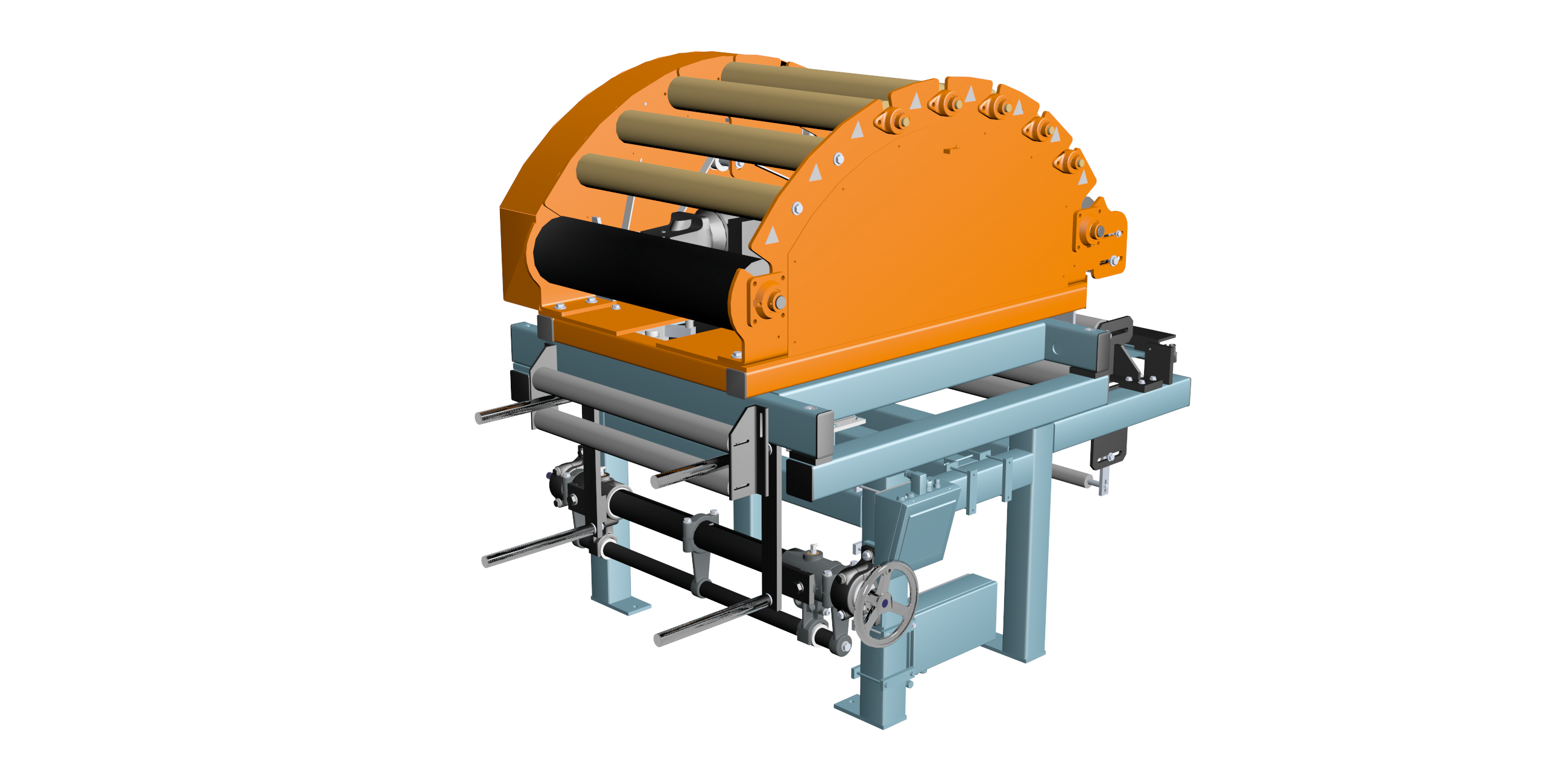

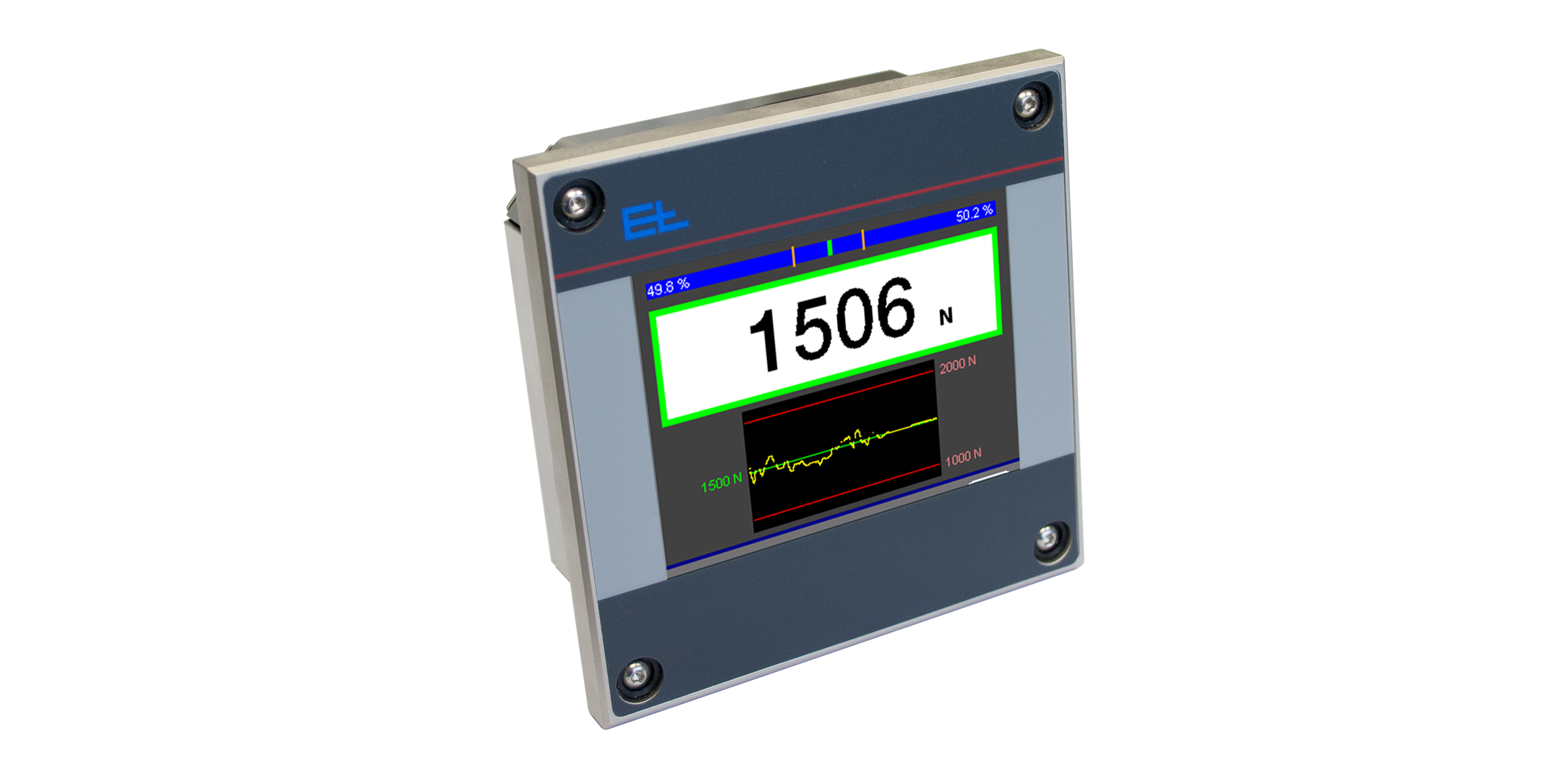

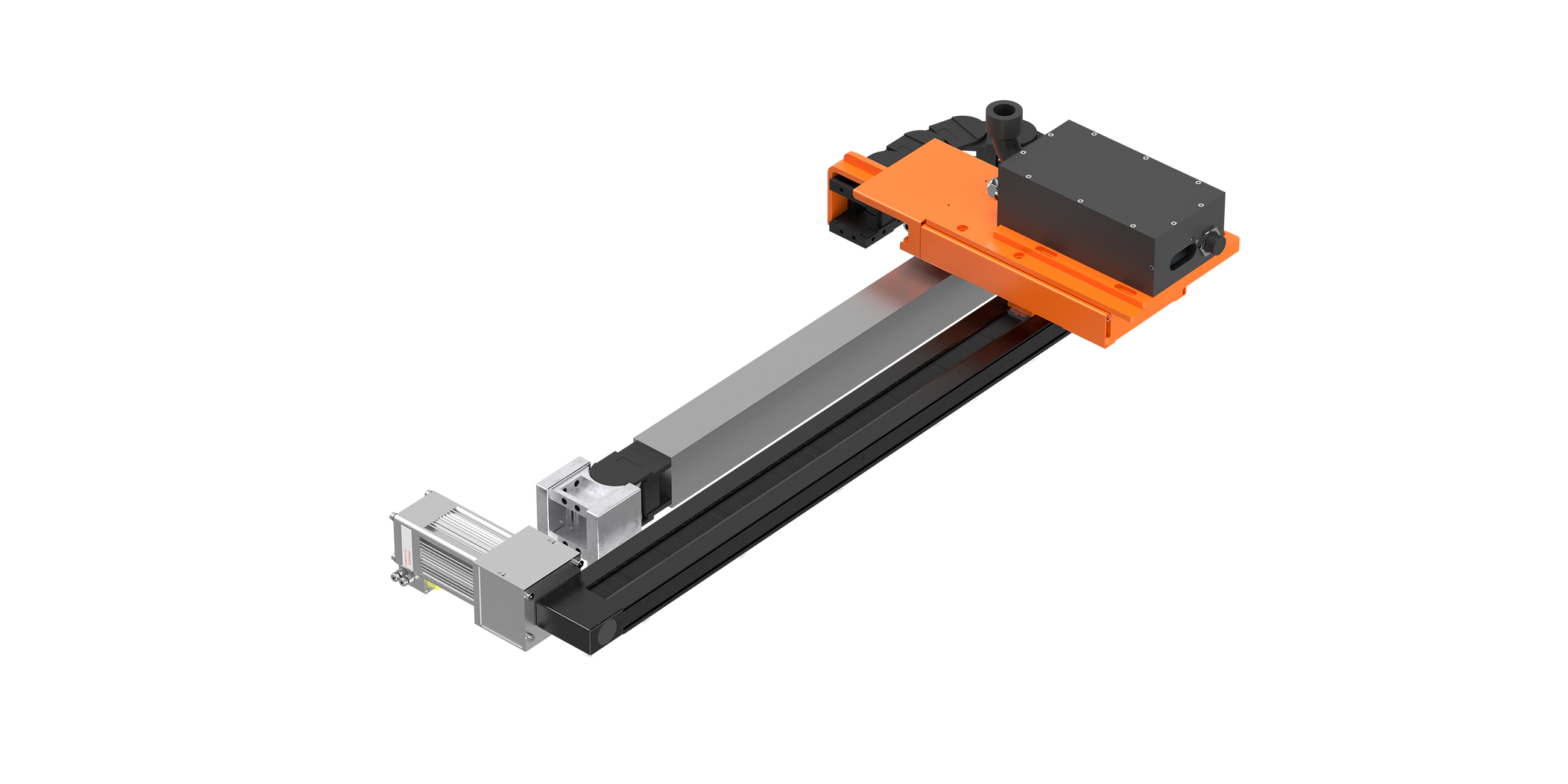

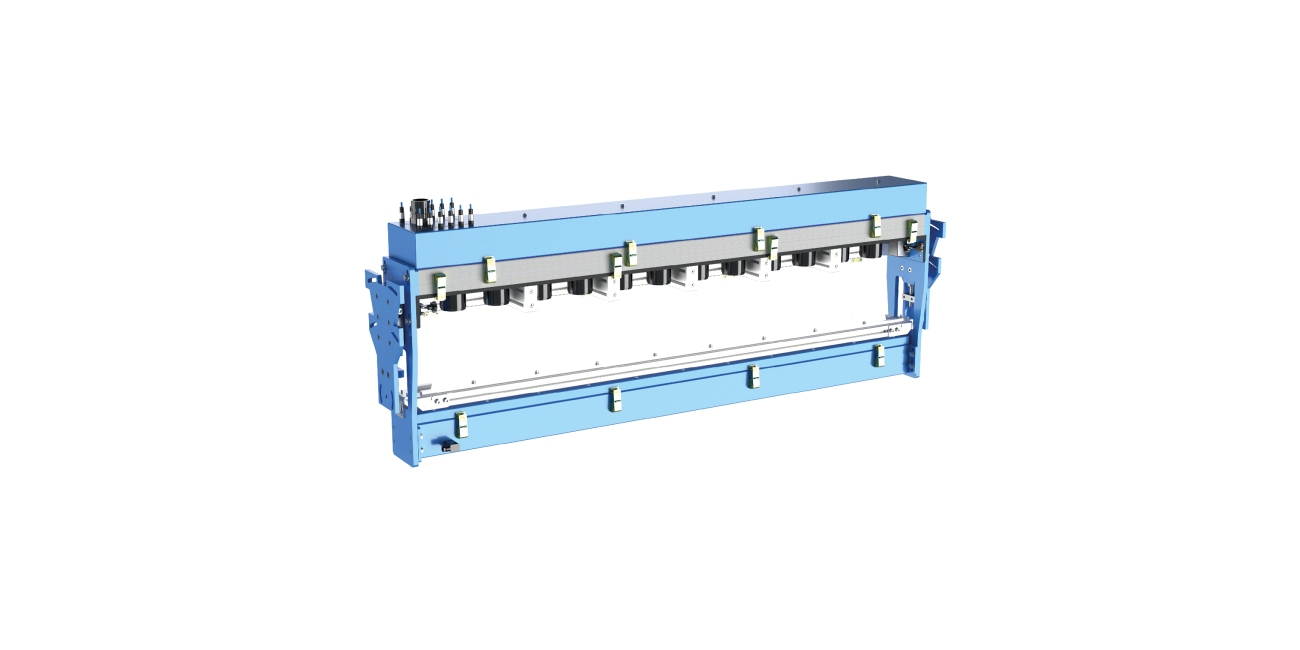

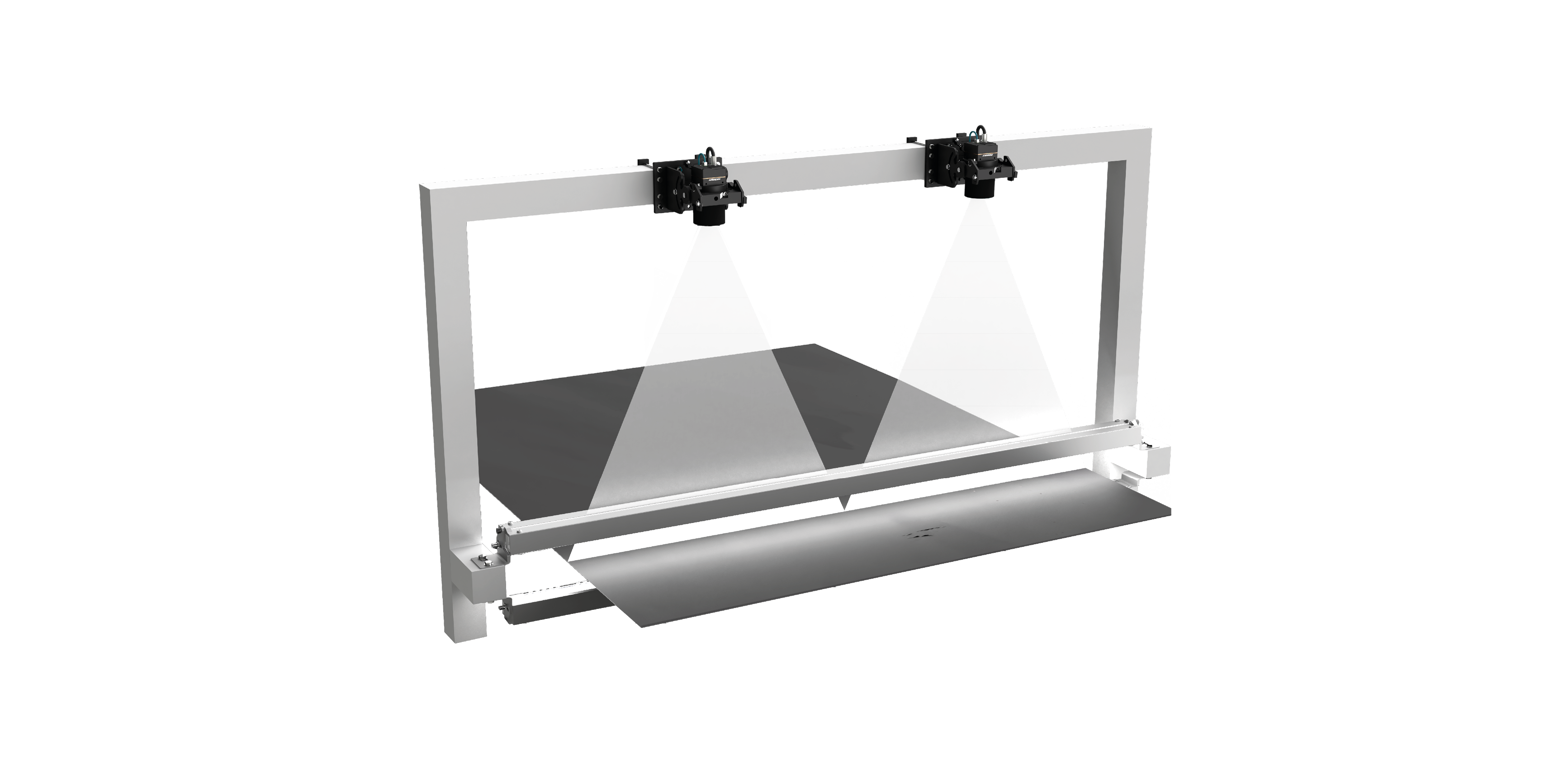

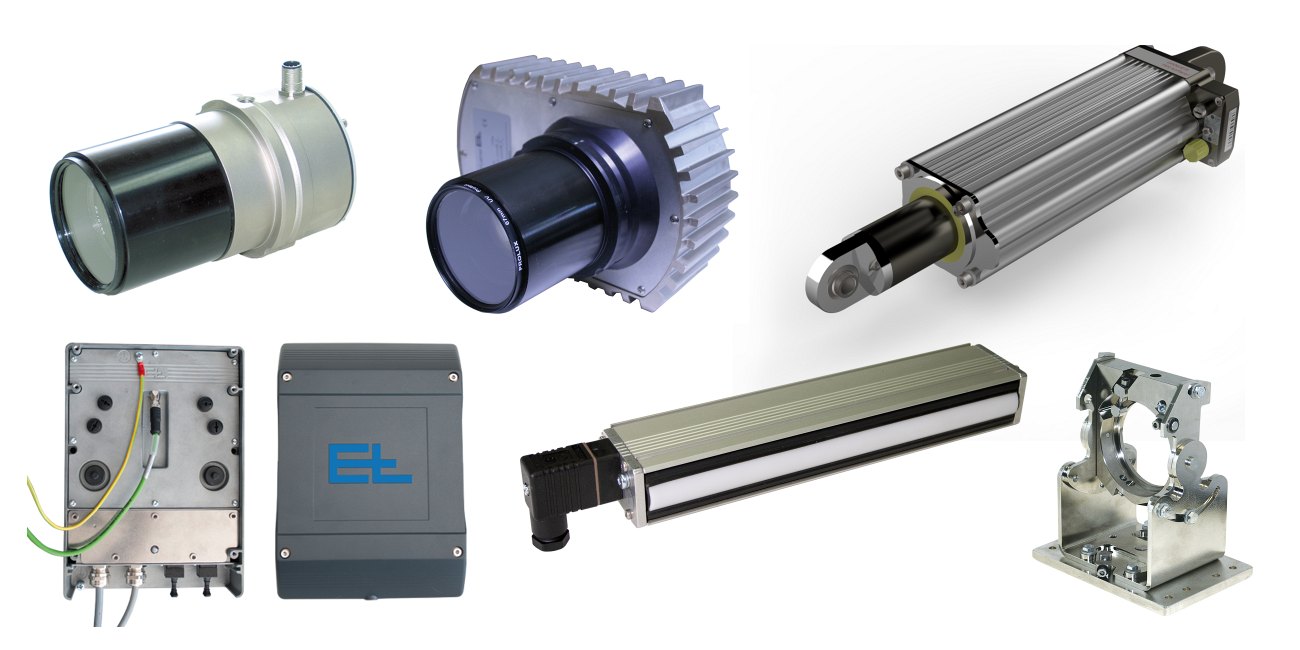

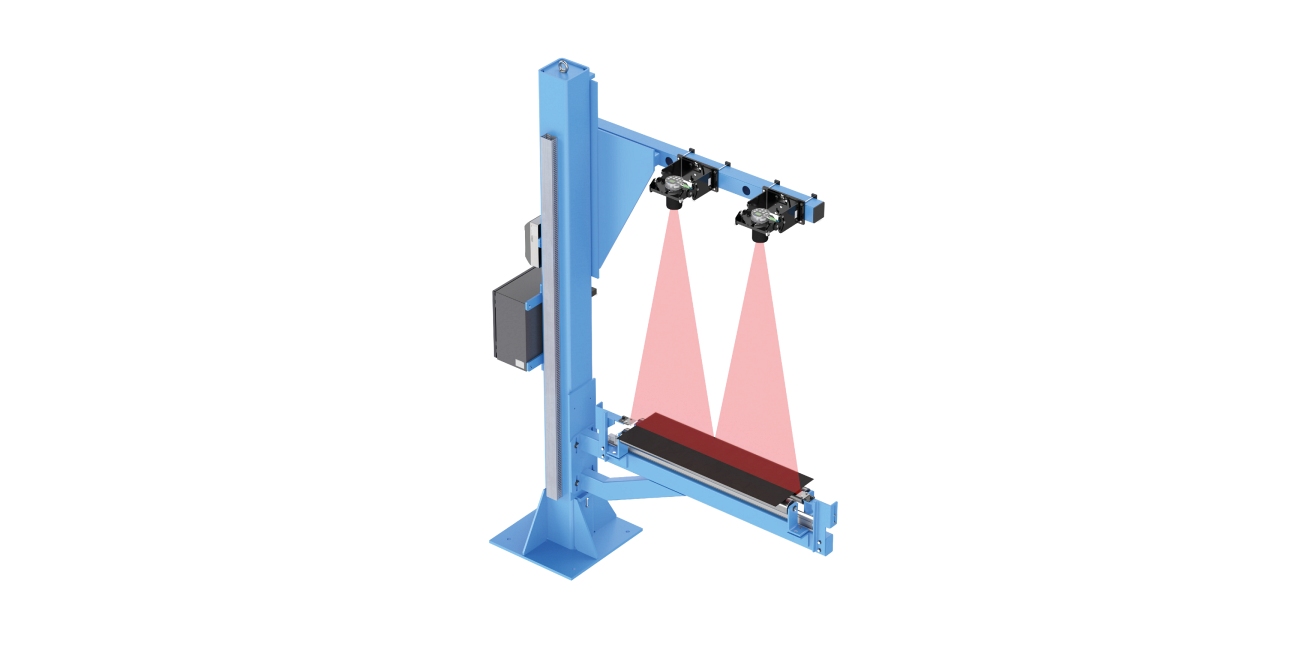

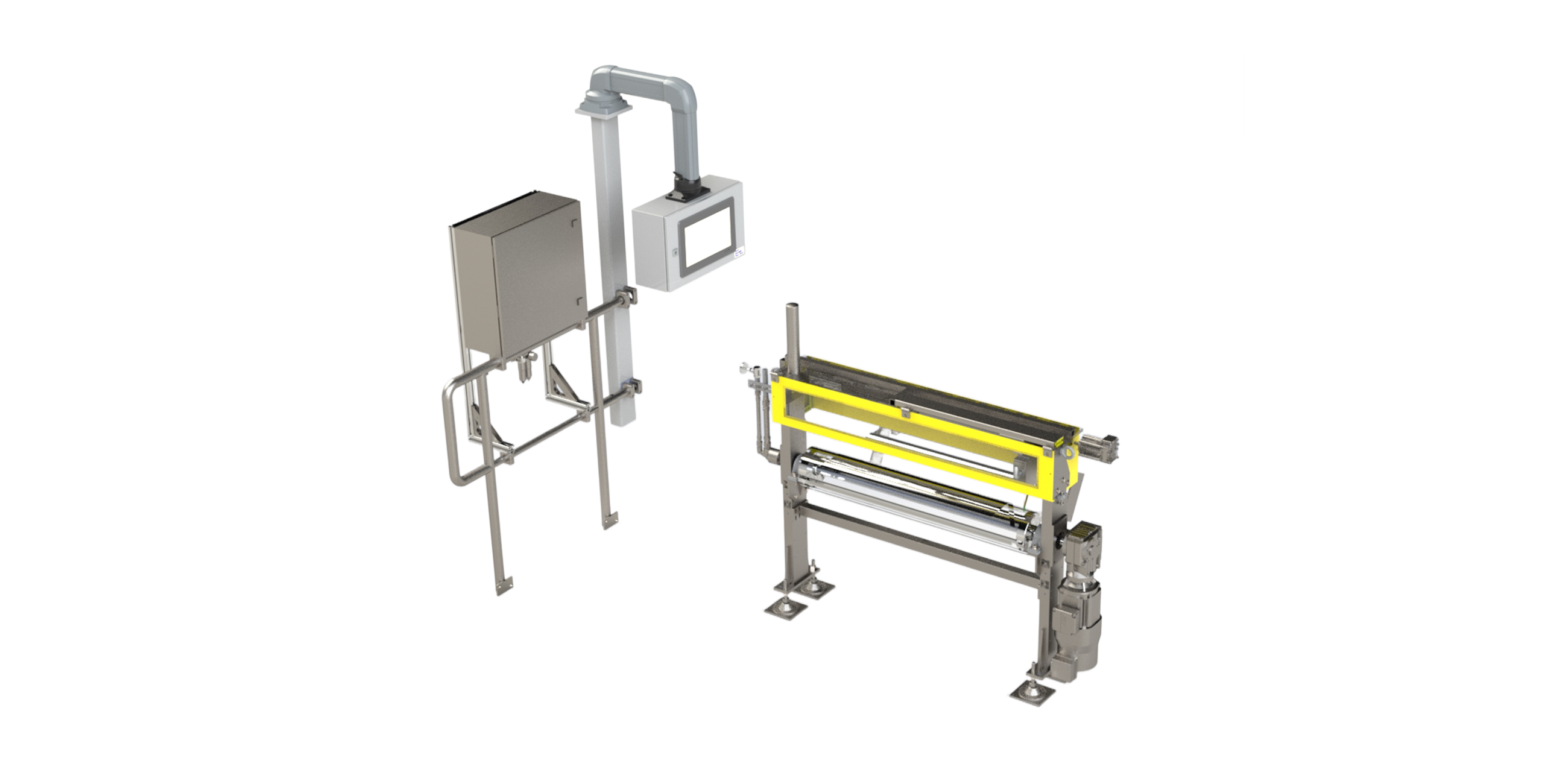

On calender lines, textile threads are fed into a calender where they are coated with several layers of rubber. In this way, an endless cord-rubber web is produced. E+L supplies all the components to keep the webs produced in position, to cut them, to laminate them with other materials and to measure their thickness. In this way, the highest quality demands are met.