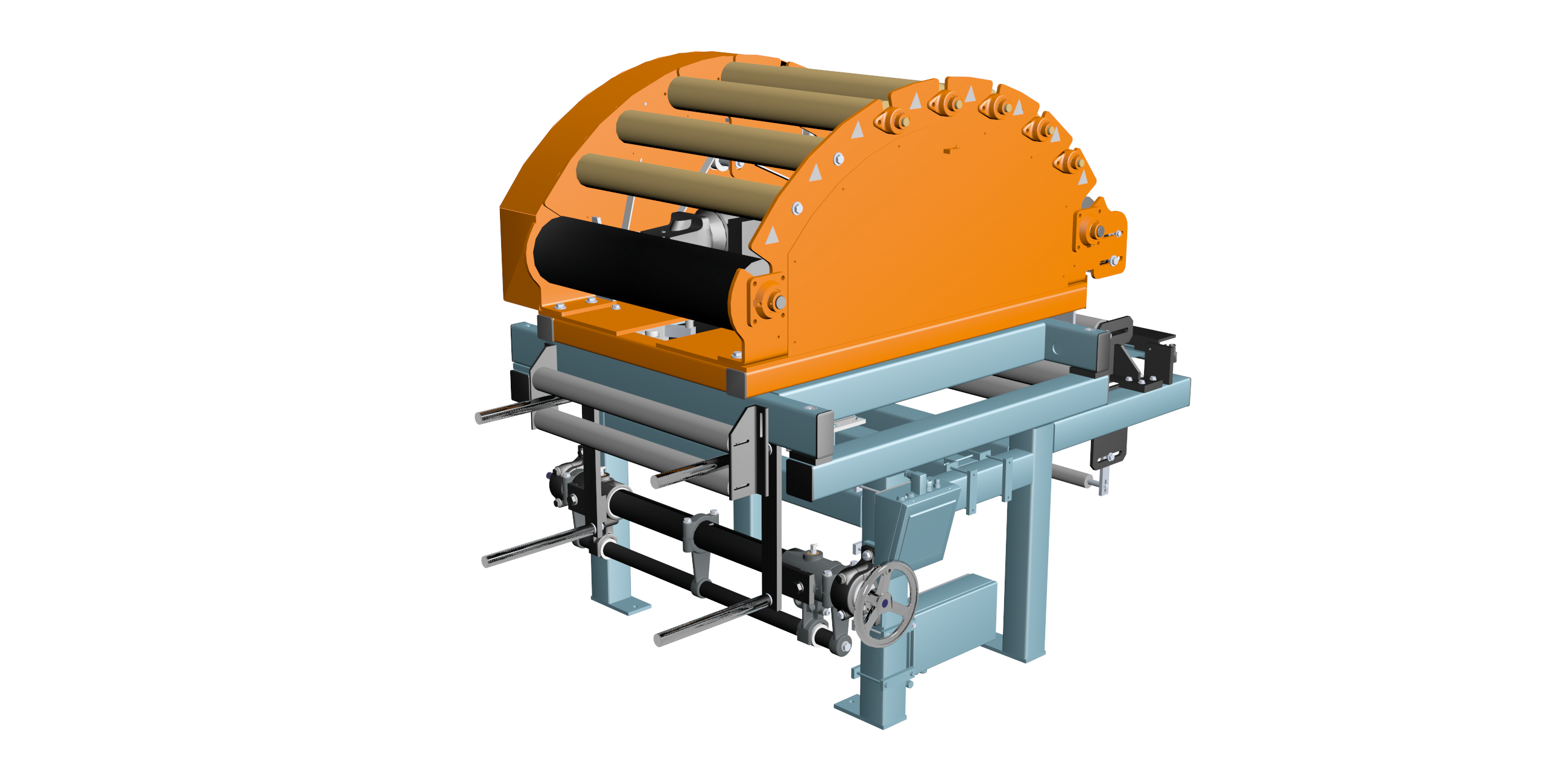

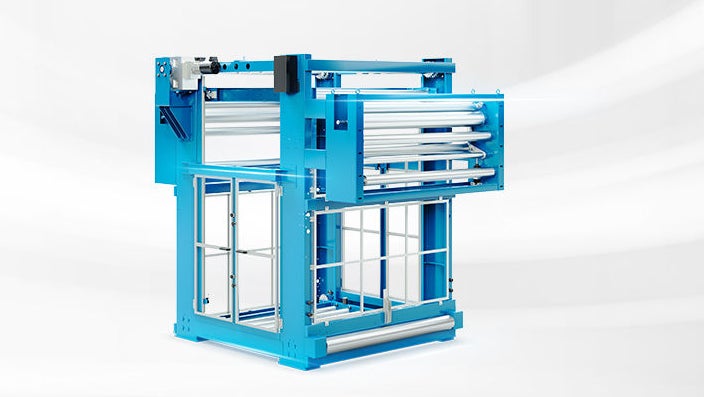

Tufted carpets have a loop facing on the user side due to the stitching process. For many carpet qualities, an open structure produced by trimming off the loop heads is required. A seam detector ensures the cutting table is lowered as the seam passes through. A metal detector prevents damage to the expensive shearing blades.