- Description

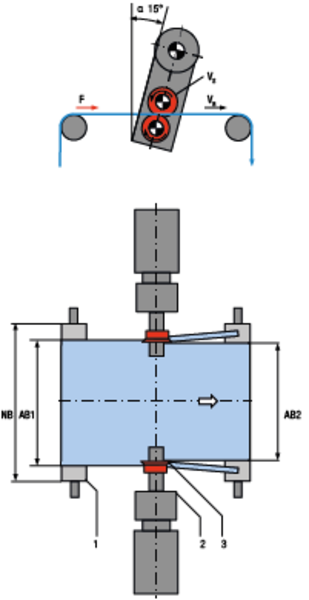

- Function drawing

Function

The upper and lower blade shafts are driven by a three-phase motor via a multi-stage spur gearbox. Different transmission ratios or the use of frequency-controlled three-phase drives allow infinitely variable adjustment of the cutting speed to the required production speed.

Area of use

The main area of application of cutting technology is production systems for paper, foil, textiles, carpet, non-woven fabric and felt webs. Installation of the cutting systems primarily takes place after the last process step before rewinding.

Application

The web cutting device can be used for horizontal and vertical web travels. Incline the web cutting device by 15° for an optimal cutting position. The cutting speed of the cutting systems should be approx. 5 to 10 % greater than the web speed. A web guider in front of the cutting unit optimizes cutting and prevents the web from running away from the blades.

Legend

1 = Guide roller | 2 = Three-phase drive | 3 = Shear cut | α = Inclination angle | AB1 = Operating width | AB2 = Operating width after edge cut | NB = Nominal width | F = Web tension | VB = Web speed | VS = Cutting speed