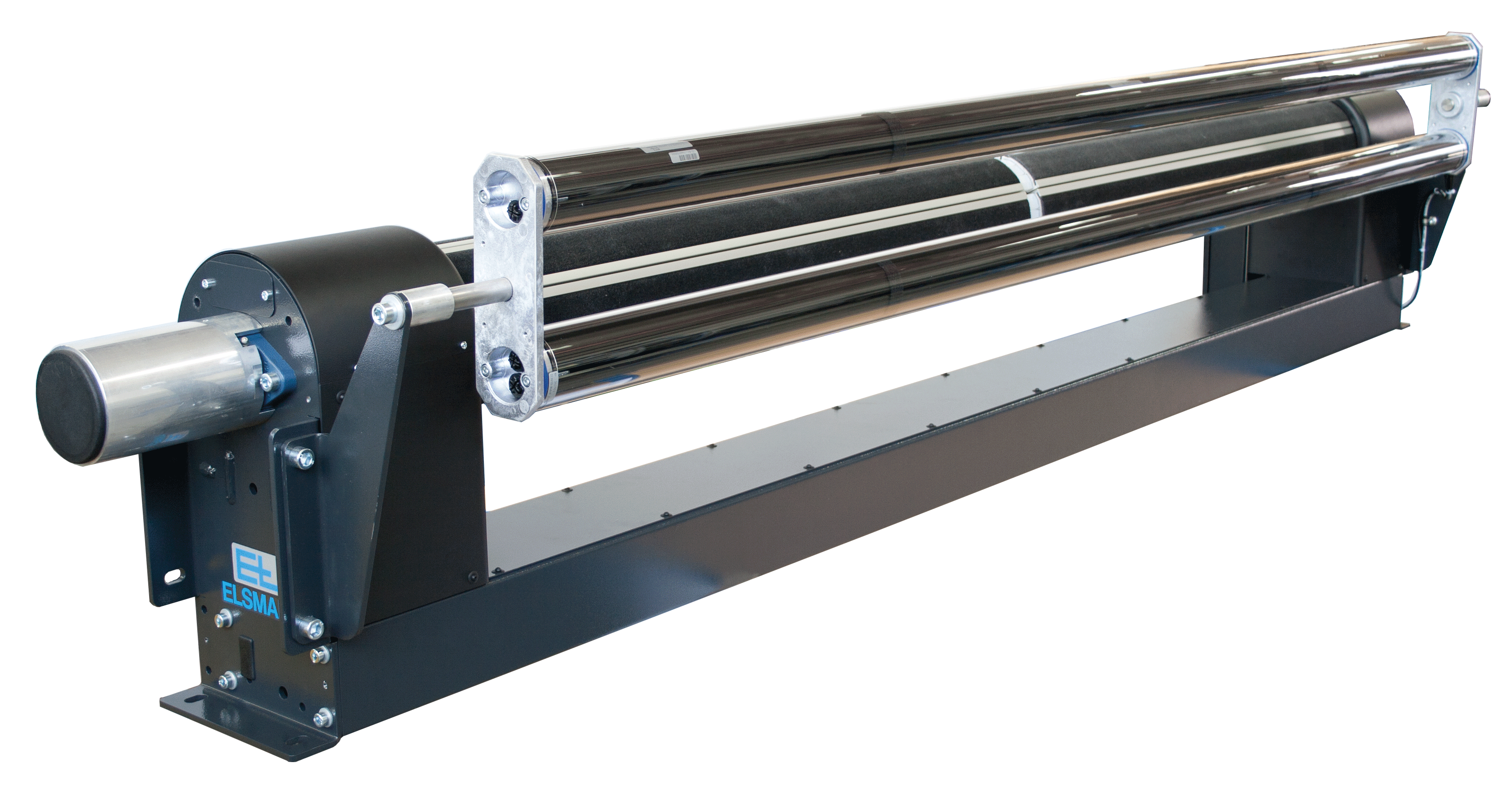

Offline station transfers inner liner, ply, steel belt and liner to different types of cassettes or bobbins. At the center belt conveyor the operator can also detect and remove the rubber defects. This customized machine is able to work in both running directions.

Layout

- Let-off and wind-up for bobbin with liner guider

- Roller train conveyors

- ELSMART Segmented roller guider system E+L camera

- Transfer and inspection belt conveyor

- ELROLLER Steering roller system

- Wind-up and let-off with sliding frame for different types of cassettes