Process Control for Tenters and Dryers ELMAT

- Low residual moisture control

- Exhaust temperature and humidity control

- Heat setting control

- Fabric temperature display at the output end

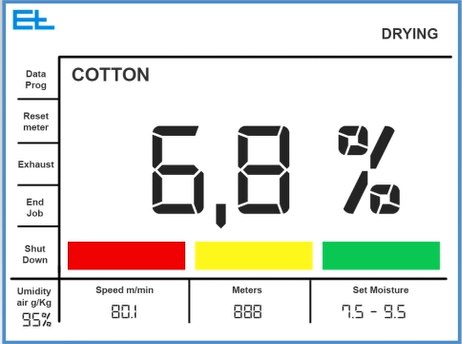

Low residual moisture control optimizes your product quality by ensuring correct residual moisture. By preventing overdrying of the web, you reduce your energy costs and simultaneously maximize the drying capacity of the dryer.

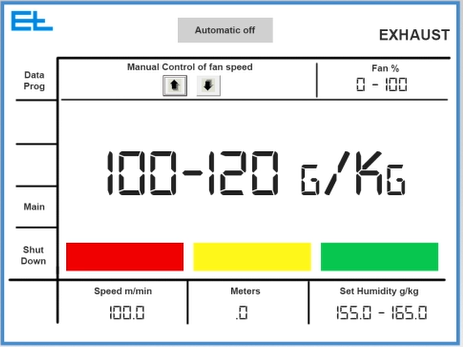

The energy consumption of a dryer greatly depends on the amount of water vapor in the exhaust air. A greater volume of water vapor means a lower volume of air that has to be warmed up from the ambient temperature to the exhaust gas temperature.

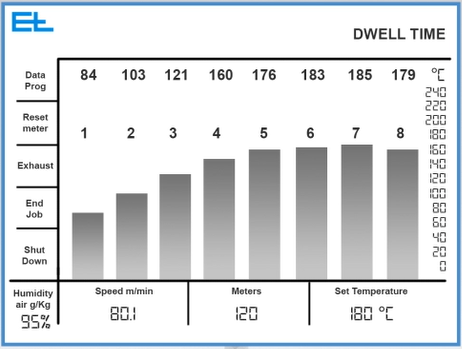

The quality of a textile made out of thermoplastic synthetic fibers depends greatly on the extent to which the correct setting parameters are adhered to. This is why exact web temperature measurement using infrared pyrometers and precise adherence to the required setting time is indispensable.

If low residual moisture measurement at the output end of the dryer is not available to the customer, they can make a rough estimation of the residual moisture of the web by measuring the fabric temperature at the output end. All of the functions outlined above are integrated into a single ELMAT system device. Operation and the display of measurement results are self-explanatory and are structured in a logical way. Special product data can, if required, be saved as parameter sets in the device memory.

ELMAT offers end customers an ideal solution for retrofitting existing drying machines. It is also ideal for mechanical engineers who want to avoid programming complex visualizations and controls themselves.

Application fields

- Tenters

- Dryers

Benefits

- Automatic process control

- Energy saving

- Constant product quality

- Easy installation

- Minimum routine maintenance

- Automatic process control

Functions

- Fabric temperature measurement in the individual areas (min. 3, max. 8) and automatic control of dwell time, in order to achieve correct heat setting (polymerization)

- Measurement of the residual moisture in the fabric and automatic control of the machine speed, in order to achieve correct drying

- Fabric temperature measurement in the individual areas (min. 3, max. 8) and automatic machine speed regulation with regard to the fabric temperature in the last area

- Absolute air humidity measurement and automatic exhaust fan speed control in order to keep the process constant

Description

Embedded industrial PC, diskless, fanless, operating system embedded, solid-state disk, 15" color LCD display, 4 touch-sensitive function keys and front USB port.