- Description

Function

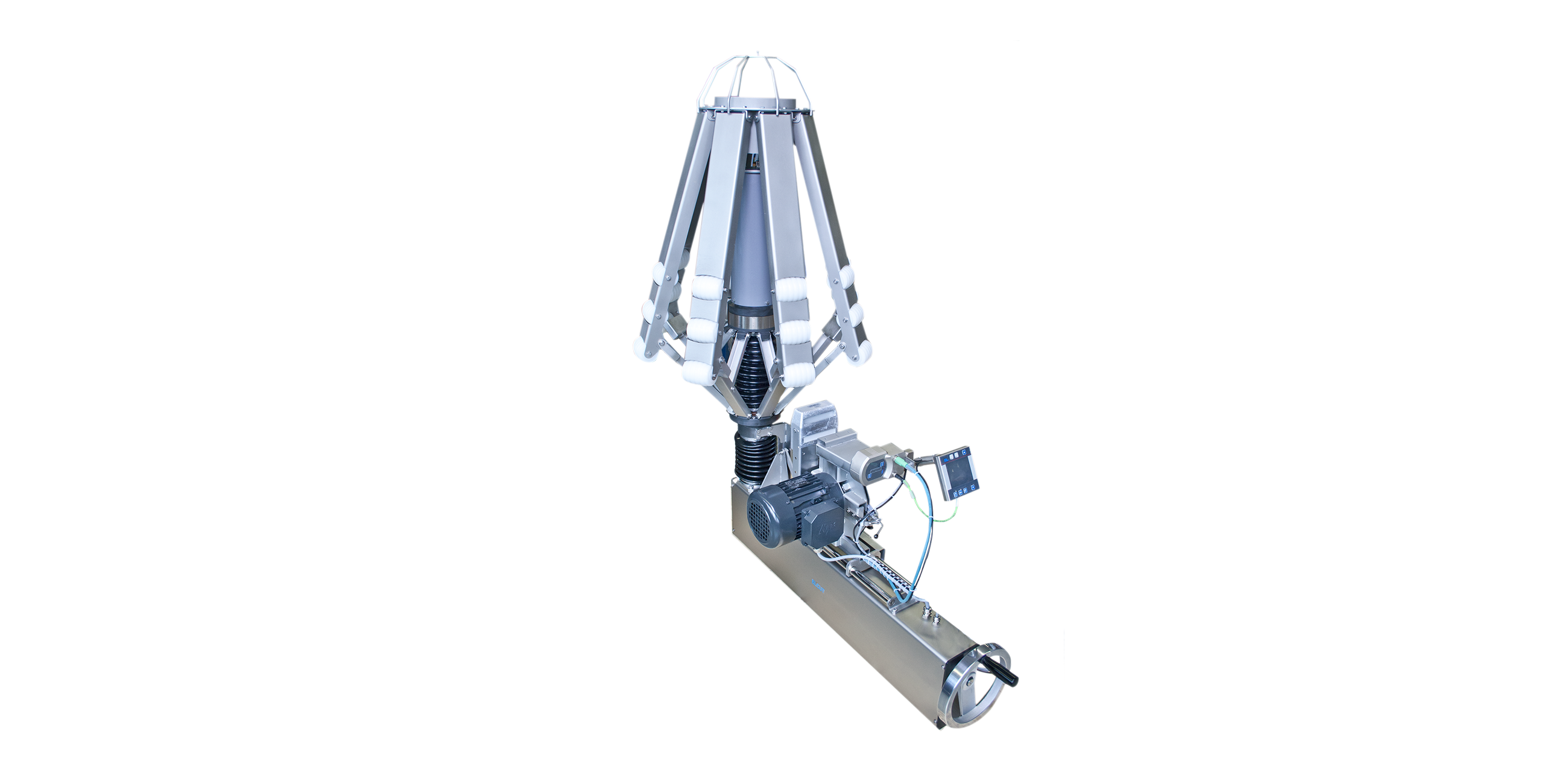

By precisely mapping the selvedge thread, it is possible for the first time ever to trace the line of the outermost warp thread with certainty. In contrast to current practice, the end of the protruding weft threads is not used as a reference point for making a rough estimate of the textile surface; instead, the selvedge thread is accessed directly. The basis for this is the E+L artificial intelligence data pool.

Area of use

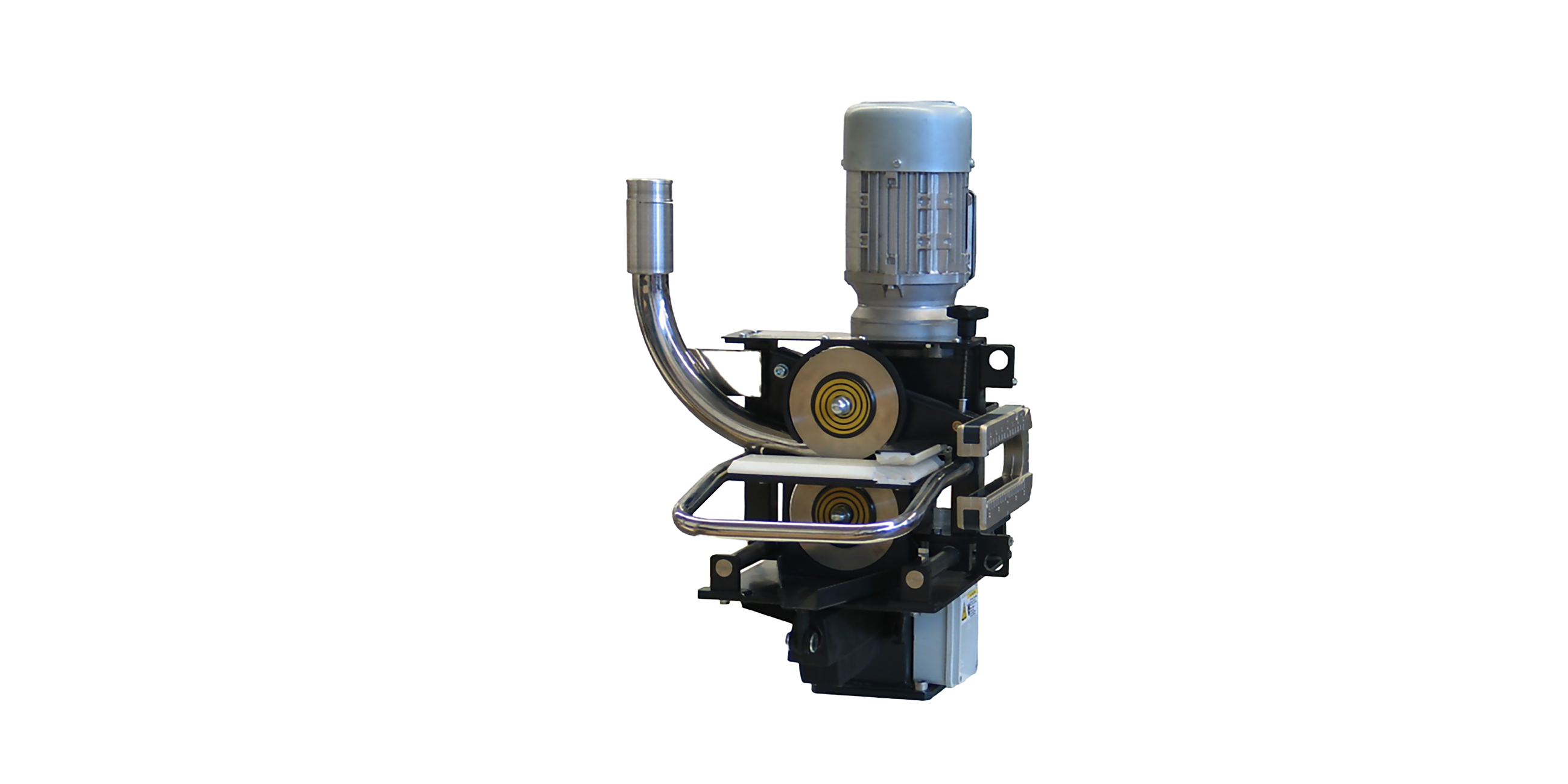

For some processes in the textile value chain, the edge must be cut after the stenter frame (e.g. digital printing). Protruding weft threads make it impossible for conventional sensor technology to find the optimal cutting line. This is where the artificial intelligence of the ELWARP sensor comes into play.

Application

Protection of peripherals in the area of digital printing (print head) and optimization of the cutting result after the drying process.