- Description

- Function drawing

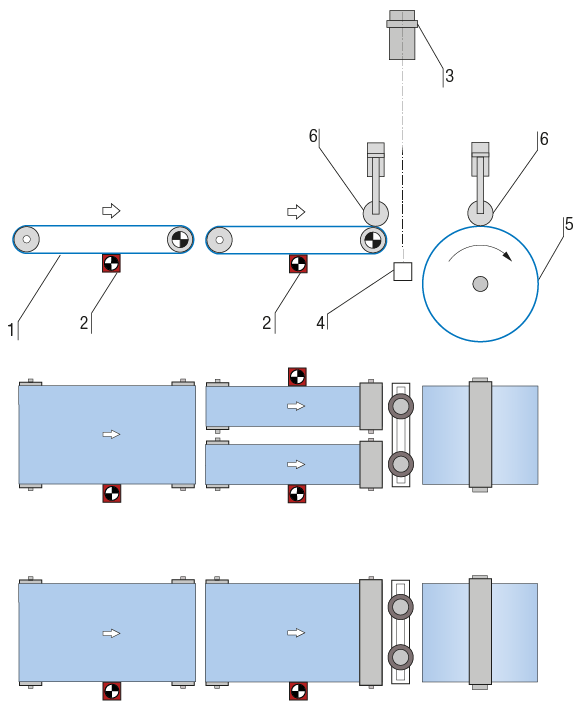

Function

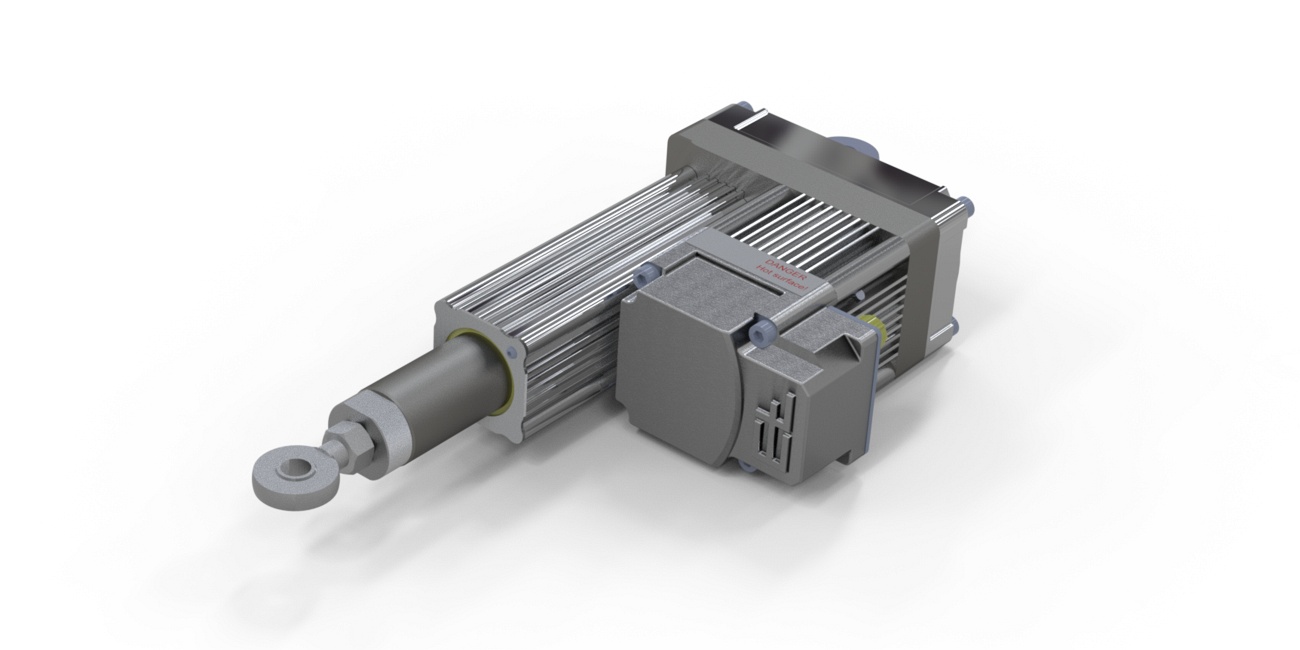

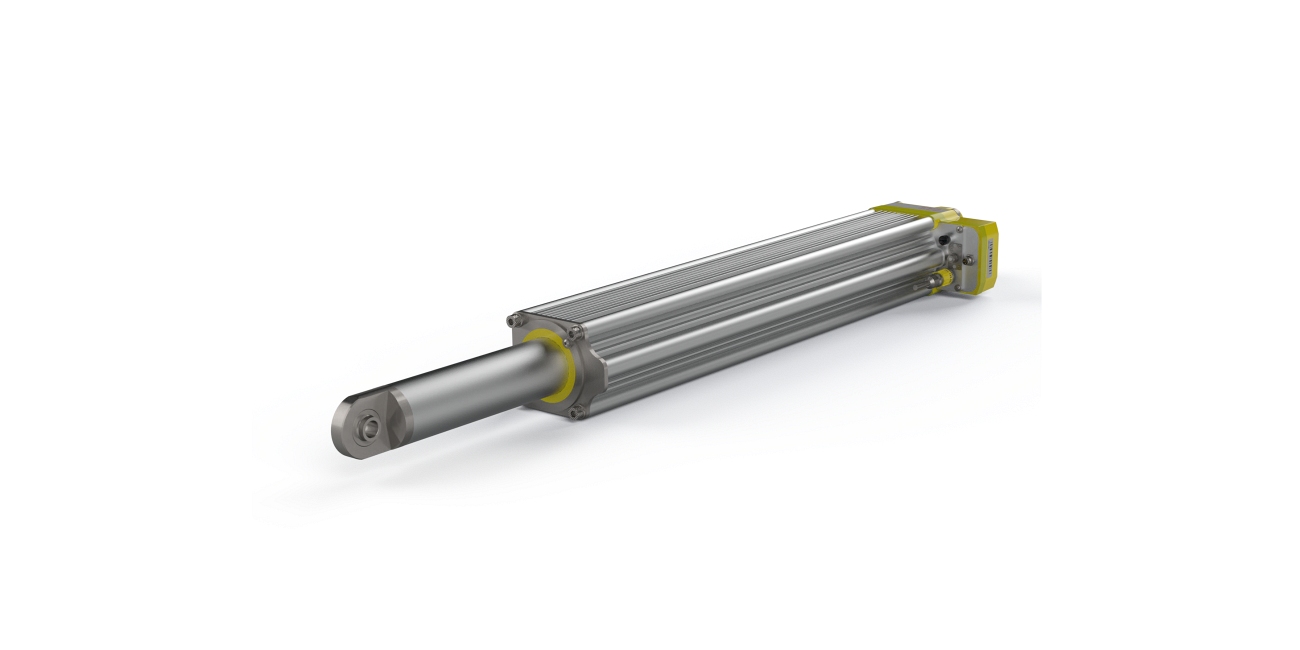

The carcass is acquired with the aid of CCD cameras or laser triangulation sensors. The sensors scan the material either before the conveyor or in the gap between the conveyor and the tire building drum. The conveyor before the camera (viewed in the direction of transport) can be moved laterally, i.e. at an angle of 90° to the material transport direction, with the aid of an actuator (AG 9), to control the material. The conveyor after the camera (magnetic) fixes the material controlled.

Area of use

The carcass control system is used in tire building machines. It controls the various materials that form the carcass before they are applied to the tire building drum.

Application

The various materials for the carcass arrive at the tire building drum via a final conveyor belt. Control can be by means of separate conveyor belts that are moved synchronously for wide materials, or by means of one wide conveyor belt. Narrow strips are then mostly pre-assembled.

The sensors are either in front of the drum or the final conveyor belt.

If the sensors are in front of the drum, the required control criterion is acquired and the material applied to the tire building drum by moving the conveyors in parallel.

If the sensors are in front of the final conveyor belt, the position of the materials is acquired and saved. The material is then applied to the tire building drum by moving the final conveyor in parallel based on the saved position data.

Depending on the selection of the sensor used, hole detection is also possible in addition to the position control.

Legend

1 = Conveyor belt | 2 = Actuating drive | 3 = CCD camera | 4 = Light transmitter | 5 = Building drum | 6 = Locking roller

Carcass control systems