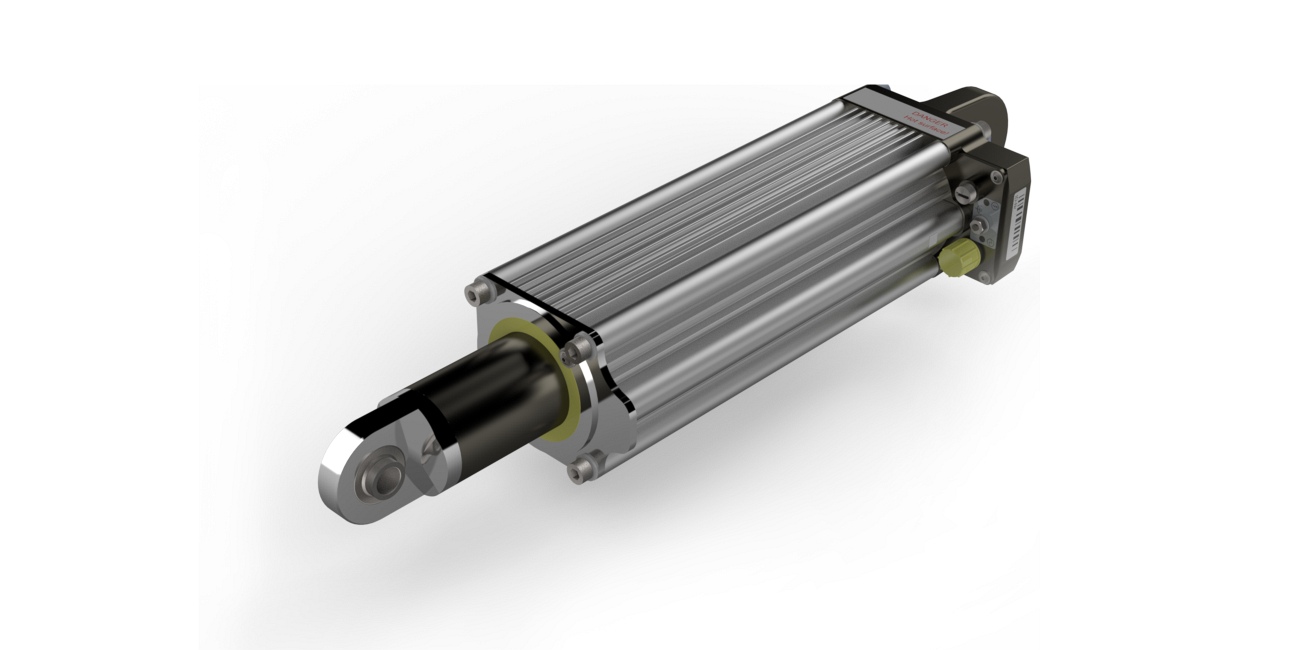

- Description

- Function drawing

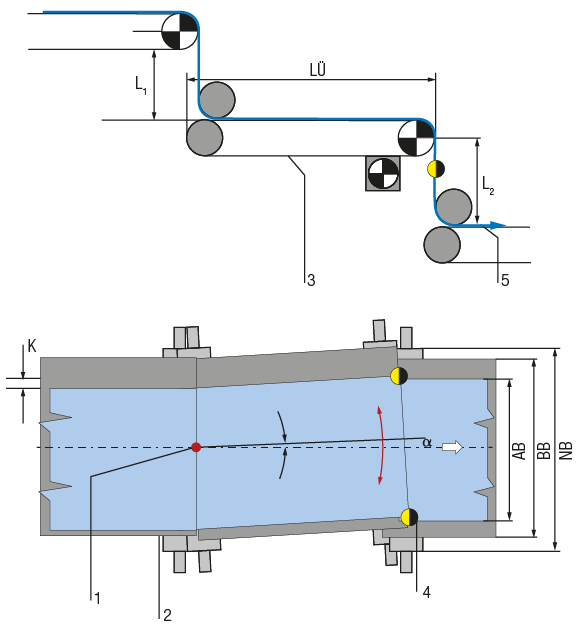

Function

On a conveyor belt control system, the web changes direction four times, each time by 90°. A pivoting conveyor belt forms the basis here. Its pivot point is located on the infeed plane. Lateral web corrections can only be achieved by pivoting around this pivot point.

Area of use

Wherever rubber webs are transported on belts, these belts can also be used for web guiding.

Application

Care must be taken to ensure both the incoming and outgoing rubber web enter and exit at an angle of 90° to the conveyor belt. The infeed and exit path should be the equivalent of at least 50 percent of the maximum web width. The sensor must detect the rubber web as closely to the exit point from the conveyor belt as possible.

Legend

K = Web correction | α = Angle of cut edge | AB = Operating width | BB = Belt width | NB = Nominal width | LÜ = Transfer length | L1 = Infeed path | L2 = Exit path | 1 = Pivot point | 2 = Infeed conveyor belt | 3 = Conveyor belt | 4 = Sensor | 5 = Fixing conveyor belt

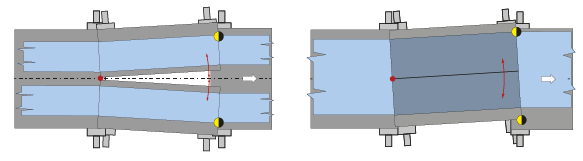

Options

Option 1 Option 2

Operation in split mode: sidewall control Operation in coupled mode: inner liner control

Conveyor belt control system