WE KNOW THE GRAPHICS INDUSTRY

WEB INSPECTION

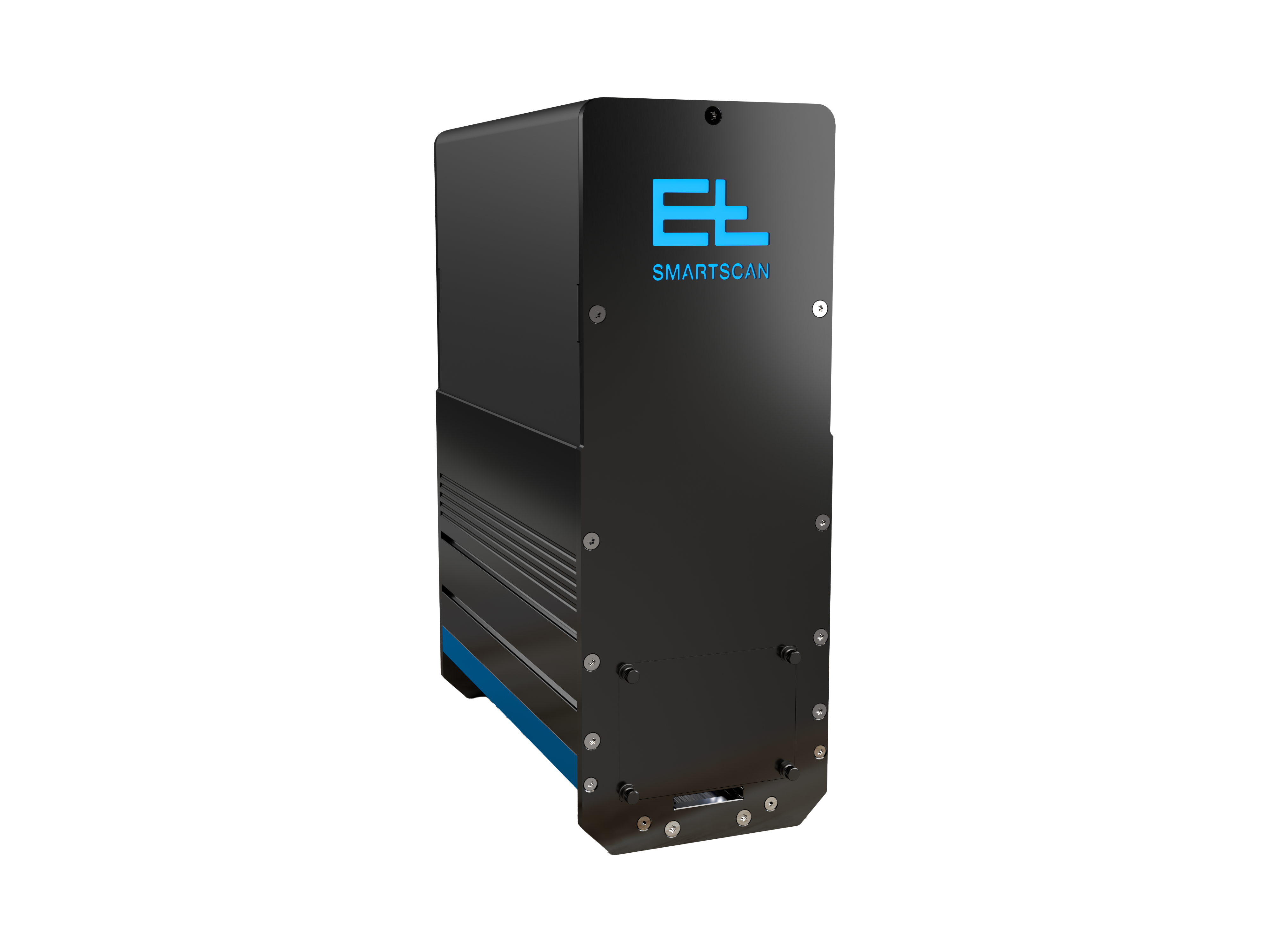

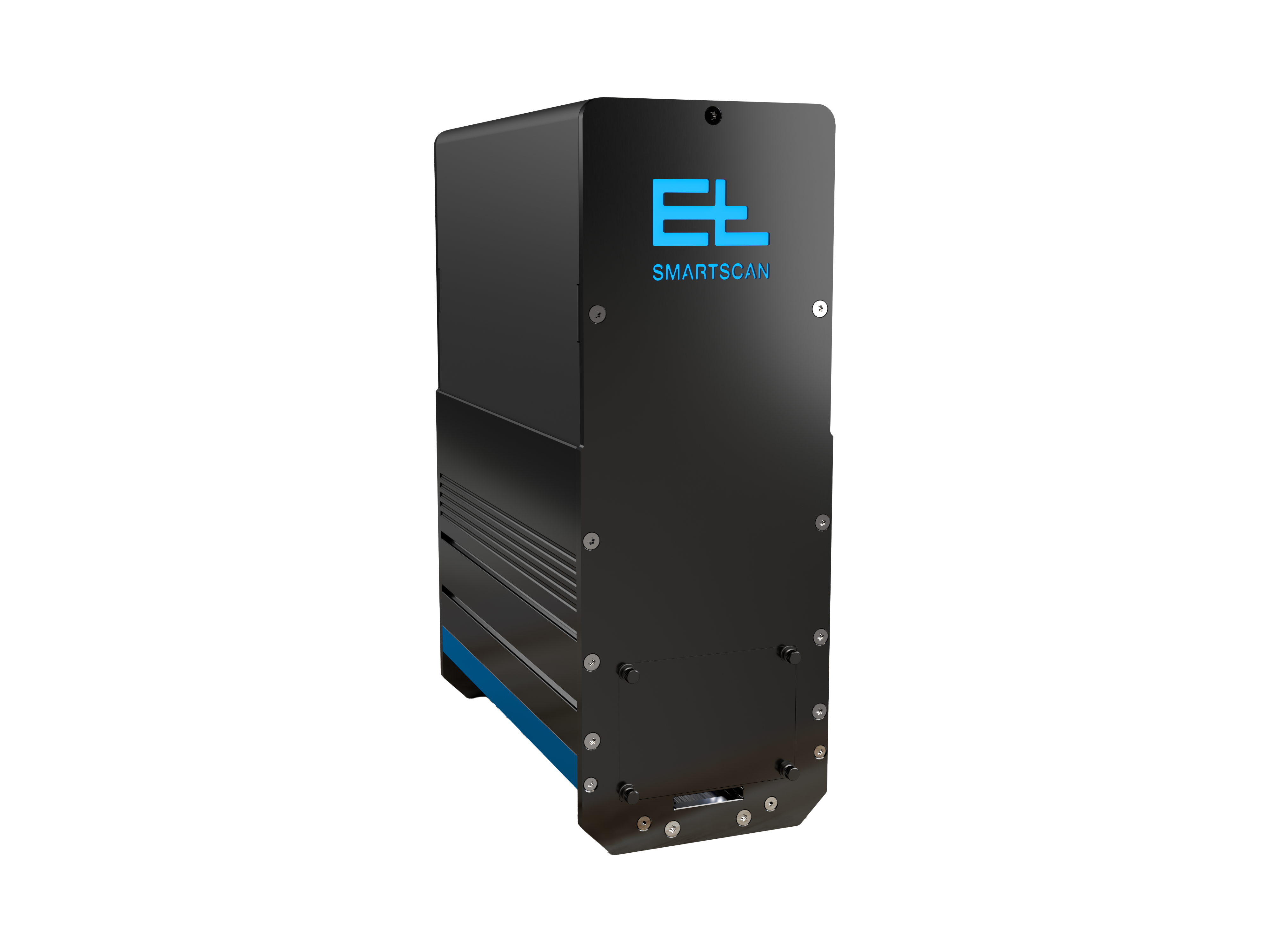

Print image inspection | SMARTSCAN

200% INSPECTION · 100% AFFORDABLE · 0% DEFECTS

- Camera system with unique 200% inspection function

- For printing and finishing machines in label and narrow-web applications

- Continuous double inspection of the entire width and length of the web

- Web monitoring with zoom function

- Detection of print defects, missing labels, unremoved matrices, splice points, flags, color defects, damage, etc.

- Counting function for labels and defects

- Log function for the inspection runs

- Signal output for customer-side defect location or to activate signal lamps

The SMARTSCAN 200% concept is unique on the market

WEB GUIDING

Elegant pivoting frame system | ELGUIDER DRB11

100% space-optimized solution

- Maximum optimized design

- Highly precise and highly dynamic

- Component replacement via auto-restore function

- Intuitive, guided commissioning

- Virtual operation concept

WEB MONITORING

Web monitoring system | ELSCAN OMS5

Due to a completely new lighting concept, ELSCAN OMS5 is perfect for the printing market. Irrespective of whether reflecting foils/films, paper with varying properties, whether transparent or opaque, OMS5 is the all-round solution for your production.

DualView – the hallmark of ELSCAN

- Technology with 2 x 18 megapixels for magnificent image quality

- Motorized crossbeam with precise, high-speed control

- Unique LED-based flash concept for all types of printing in the printing industry

- Very straightforward system integration due to the new quick alignment function

- Comprehensive synchronization concept for stable web synchronization

- Powerful processor for smooth working

- Maximum field of view 100 x 75 mm

- Maximum web width 2500 mm

Software

- Autoscan functions (X/Y/100%/meander)

- Digital repeat overview for fast navigation

- Position gallery with 21 storable positions

- Master image comparison in different variants

- DeltaE color monitoring

- Image stabilisation

- Automatic job change detection

- Archiving of repeat orders

Black Line – the new product line of the E+L vision world

Latest features encased in a black design

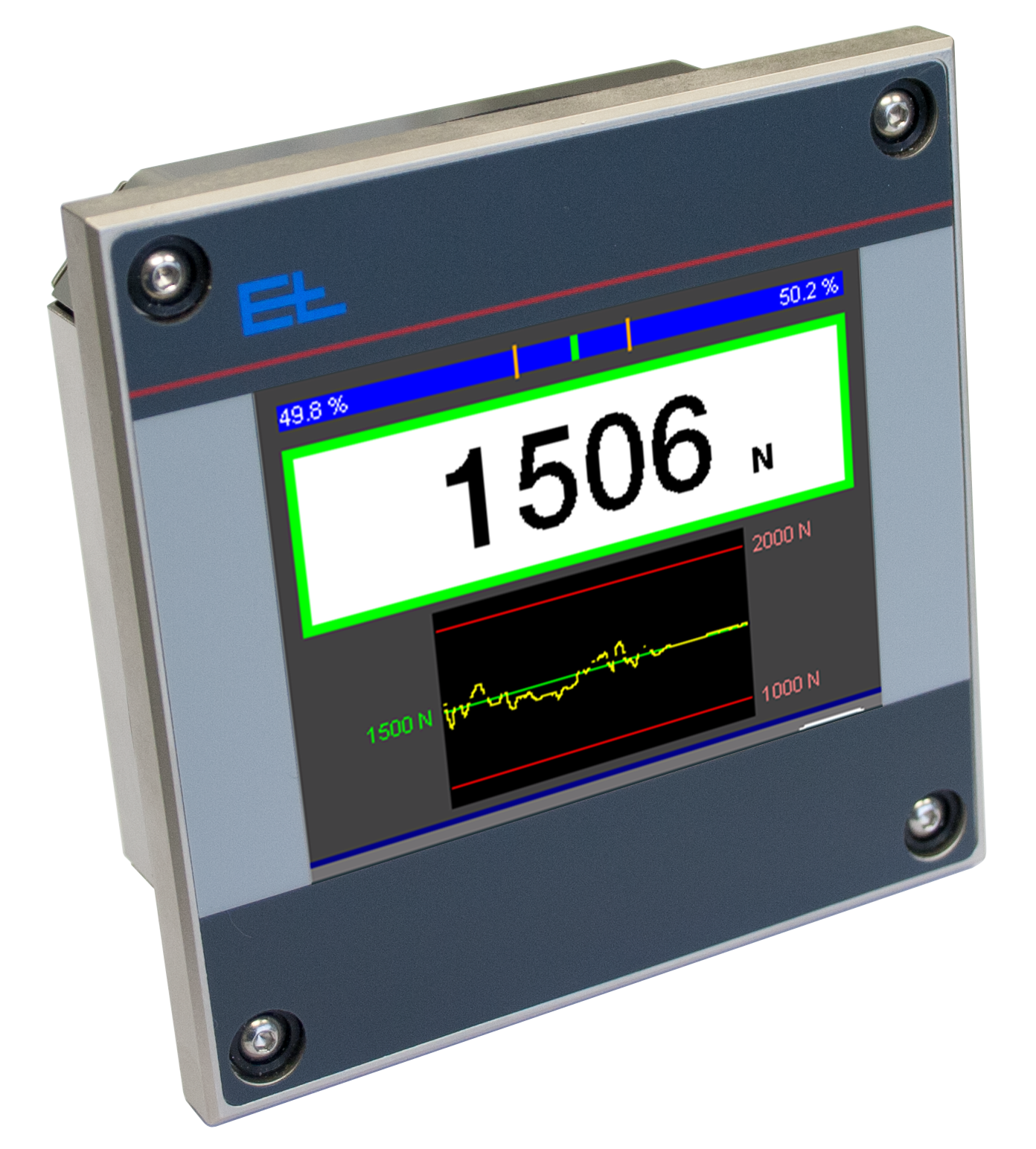

WEB TENSION

Detection and control of the web tension | ELTENS

Eliminate web tension errors, increase productivity

- Aluminum roller with fixed axle and two integrated load cells

- Various mounting options

- Highly reliable in operation thanks to overload protection up to 10 times the nominal

measuring force - Maximum flexibility due to different roller diameters from 60 to 200 mm

- For measurements in a horizontal direction, the weight of the roller does not affect the

measured result

MORE PRODUCTS

EL.MOTION

Drive technology for Industry 4.0

- Automatic System Identification ASI (auto tuning)

- Integrated drive technology

- Absolute positioning

- Industrial networking

- Drive-integrated safety function STO

Stand-alone sensors

For direct PLC connection

- Easy position detection

- Width measurement

- Also for transparent material

Quality assurance at the highest level

A key component of the graphic industry is the quality assurance of the production process. The prerequisite for this is the monitoring, measurement and evaluation of all the factors influencing the quality of the processes in the graphics industry. In particular, the continuous web guiding and web tension control and web monitoring have a significant role to play. With efficient monitoring functions, we offer our customers not only a considerable increase in quality but also high time and cost savings as well, as a reduction in spoilage. New functions with high customer benefits are the means to differentiate yourself clearly in global competition in the graphic industry. As the market leader, Erhardt+Leimer uses the bundled knowledge in material selection, in engineering and the production of high quality components, modules and systems in order to provide you with comprehensive support.