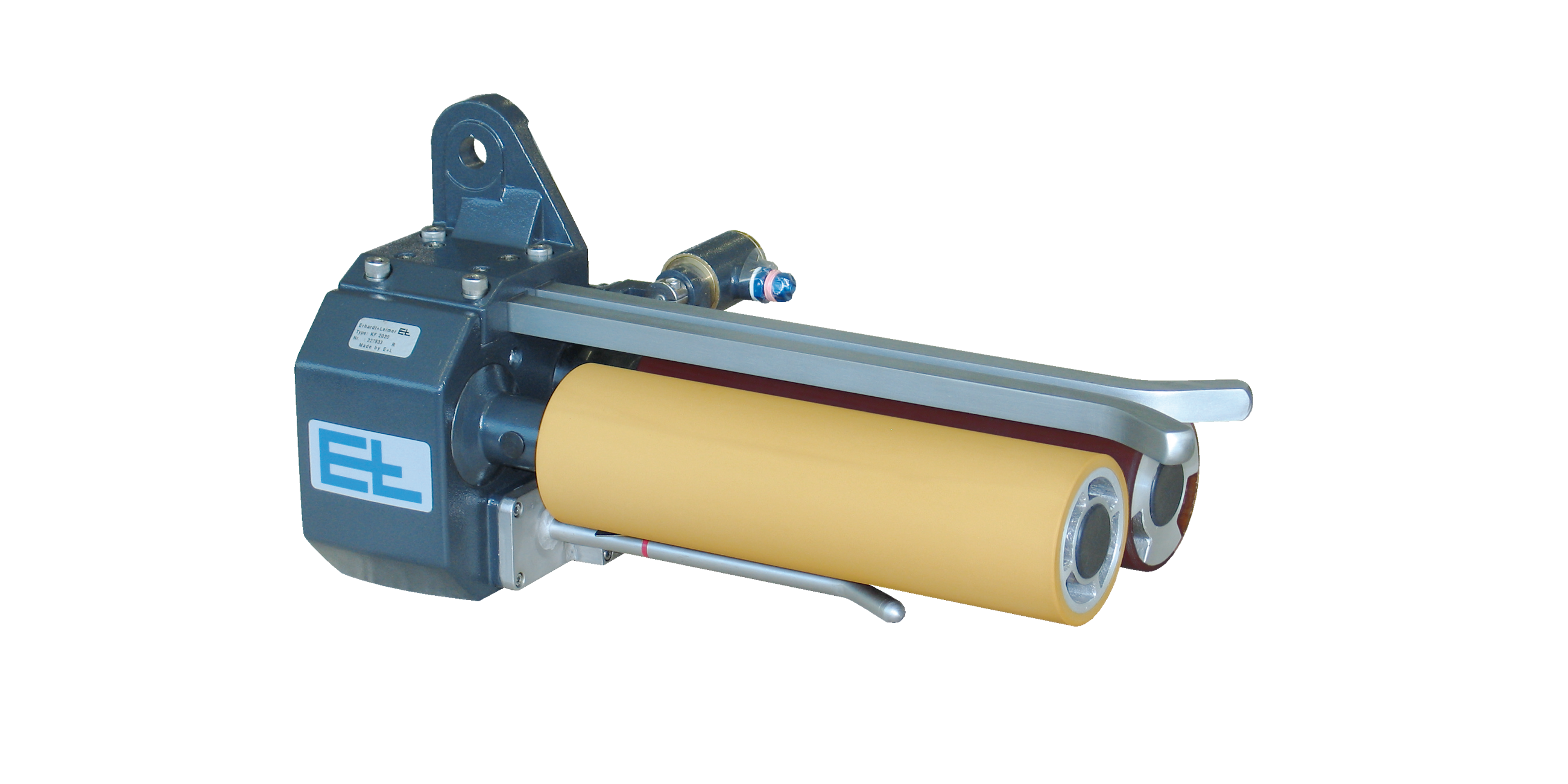

- Description

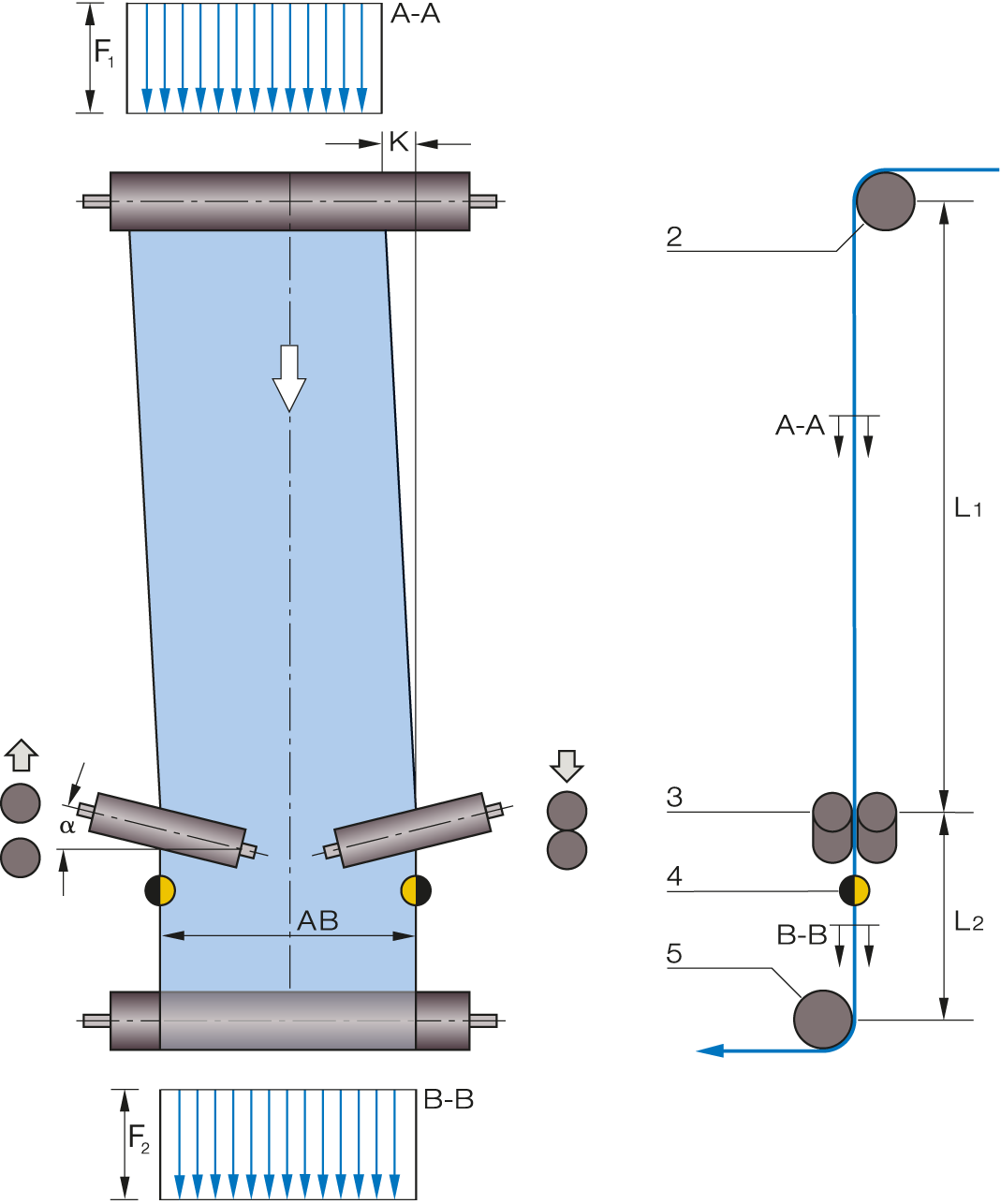

- Function drawing

Function

With the ELTWIN web guiding systems, the web edge is scanned either mechanically by a sensor lever or without contact using optoelectronics. The sensor signal controls a diaphragm cylinder or a lifting magnet that presses the control roller against the counterpressure roller. The web edge is controlled by the skewed positioning and contact pressure of the web guiding rollers. The web guiders have a compact design and are always used in pairs. An adjustment support is available in various versions for positioning of the web guider.

Area of use

ELTWIN systems are used for web guiding in textile production systems for woven and knitted fabrics.

Application

Legend

A-A = Web tension distribution at infeed | B-B = Web tension distribution at outfeed | K = Correction of the web guiding | a = Correction angle | F1 = Basic web tension at infeed | F2 = Web tension at the outfeed | AB = Operating width | 2 = Infeed roller/rod | 3 = Web guider | 4 = Sensor | 5 = Locking roller | L1 = Infeed path | L2 = Outfeed path