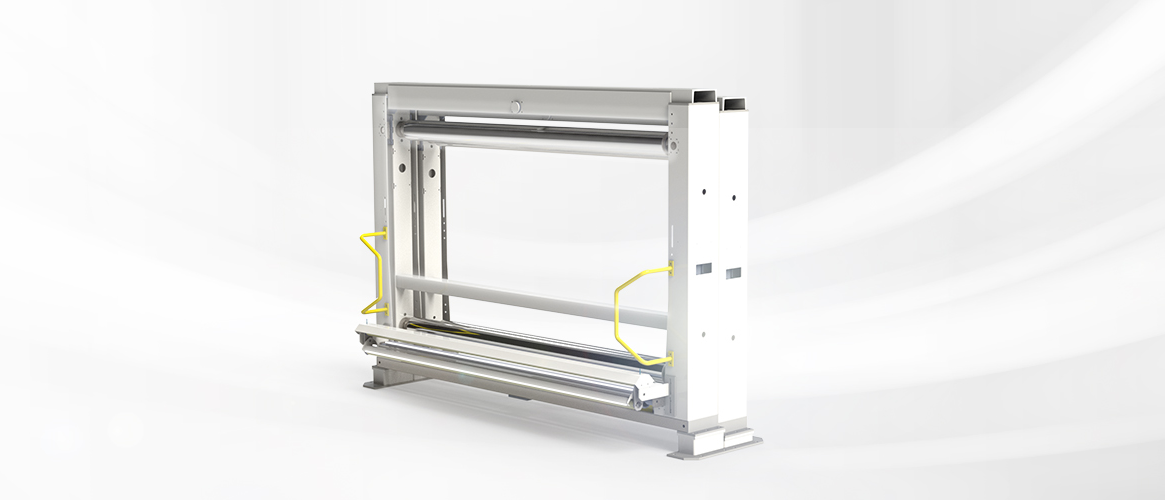

- Description

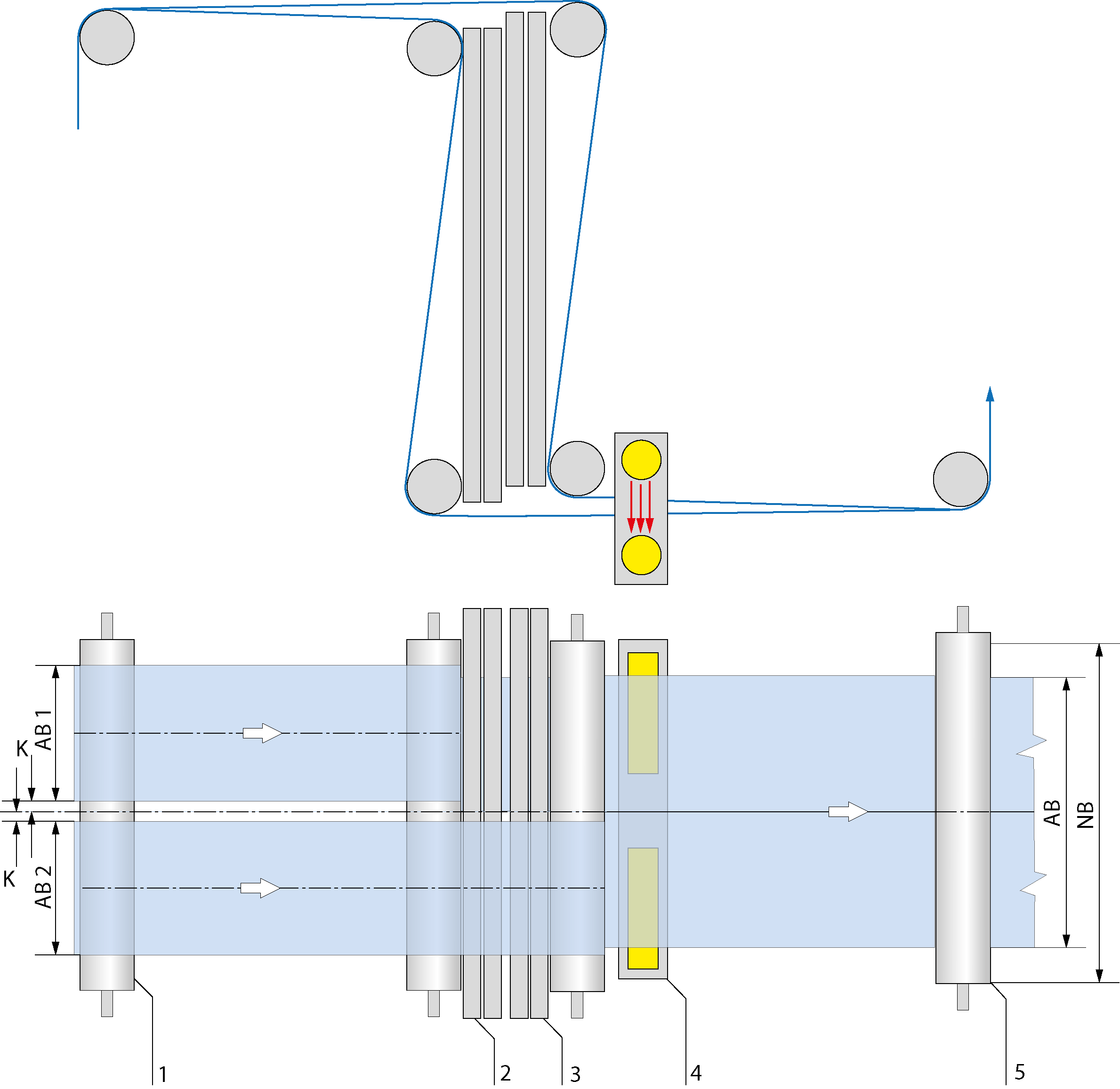

- Function drawing

Function

With a Splitweb double pivoting frame system, two pivoting frames are arranged in a mirrored position, in order to combine webs next to each other accurately on the locking roller. A wide band sensor separately detects the outer edge of each web. The position controller compares the target and actual value and outputs a corrective signal to the appropriate actuating drive.

Area of use

In the corrugated cardboard machine, in order to combine two narrow webs into a wide liner web

Application

The greater the web tension, the modulus of elasticity and the required correction, the longer the infeed, exit and transfer paths should be designed. Experience has shown that the length of these paths should be the 60 - 100 % of the web width. The sensor should be positioned behind the positioning roller, as near to it as possible.

Legend

1 = Infeed roller | 2 = Pivoting frame 1 | 3 = Pivoting frame 2 | 4 = Wide band sensor | 5 = Fixing roller | K = Infeed error | AB = Operating width | AB 1 = Operating width web 1 | AB 2 = Operating width web 2 | NB = Nominal width