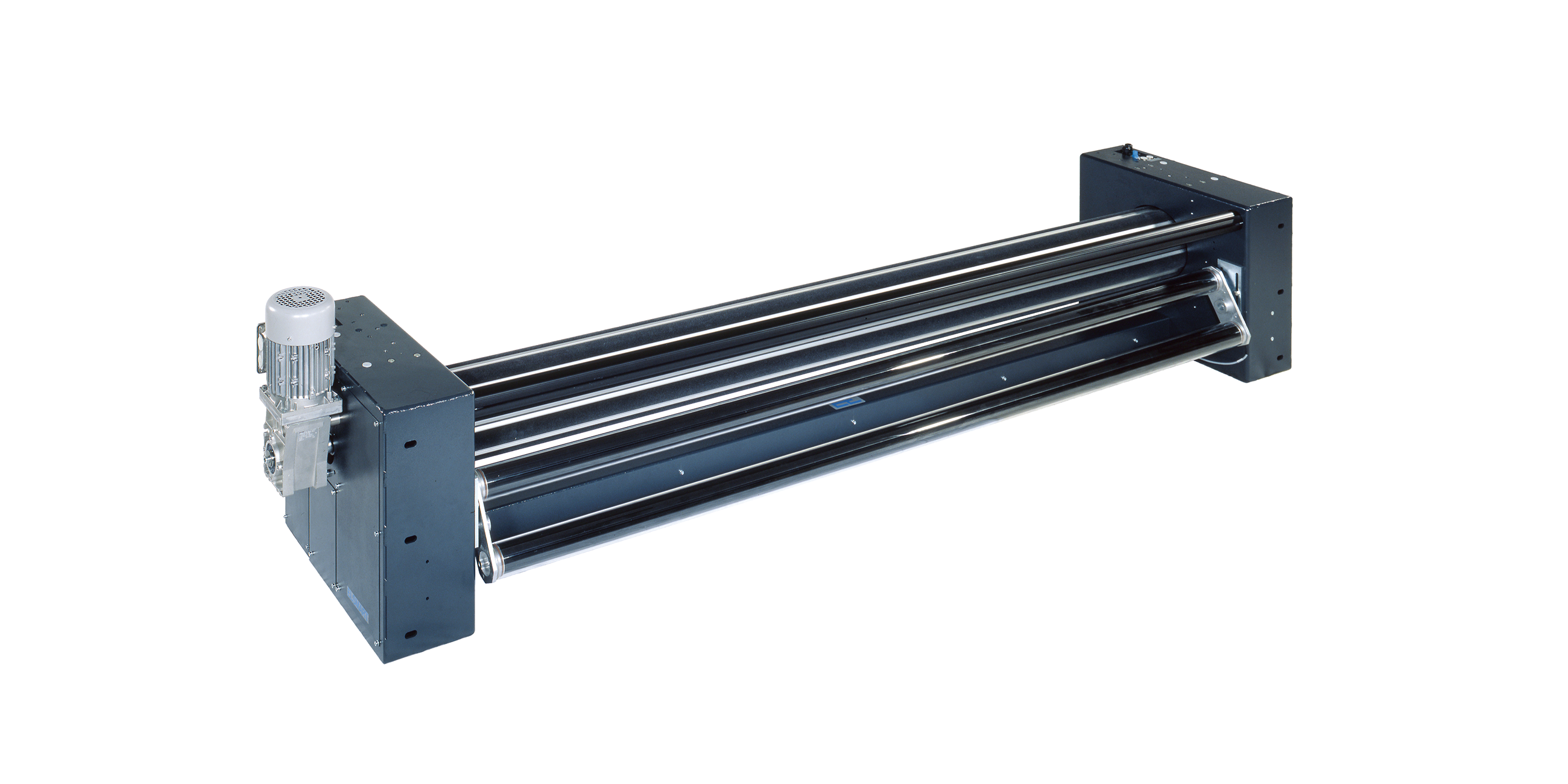

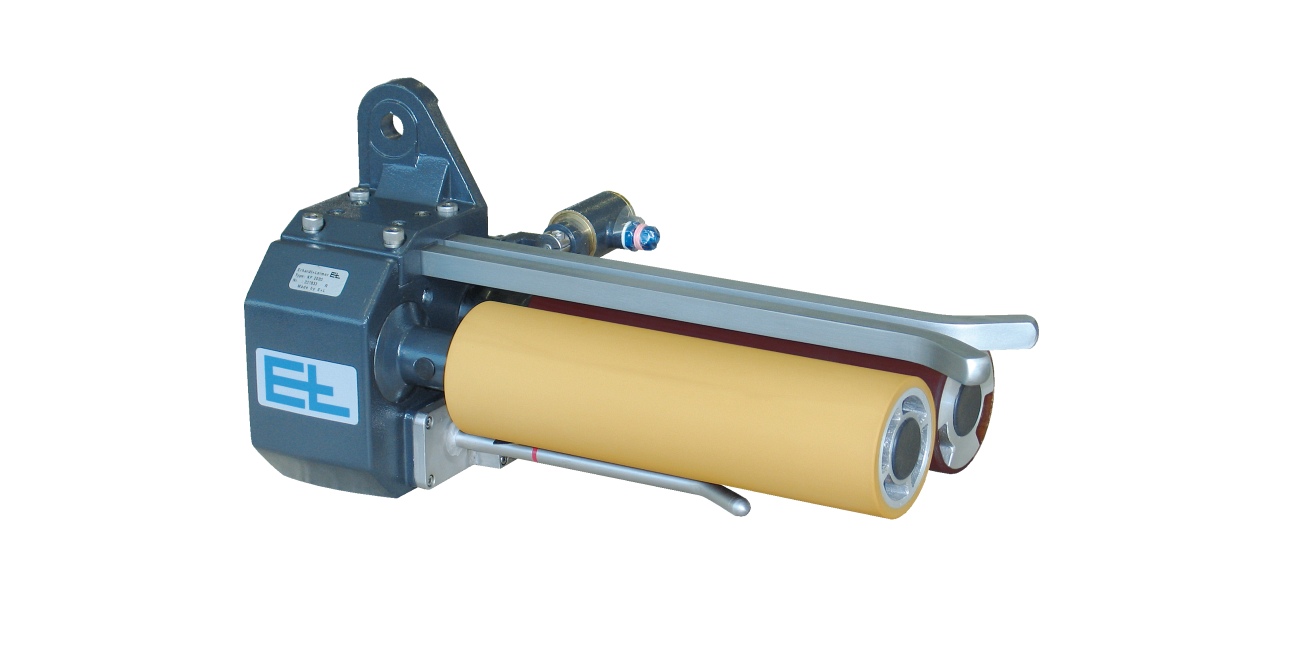

Sueding can be considered a variant of raising. It gives the textile a velvety character. Web guiding keeps the web in the correct position. Our metal detectors protect the wound sueding rollers here. These rollers are not as expensive as shearing blades or raising coatings, however damage to a sueding roller requires an immediate stop and replacement. This means second quality, loss of production and therefore unnecessary costs. The wider the web is, the more appropriate it is to use a segmented metal detector. This device indicates to the operator any metal particles within a range of 300 mm.