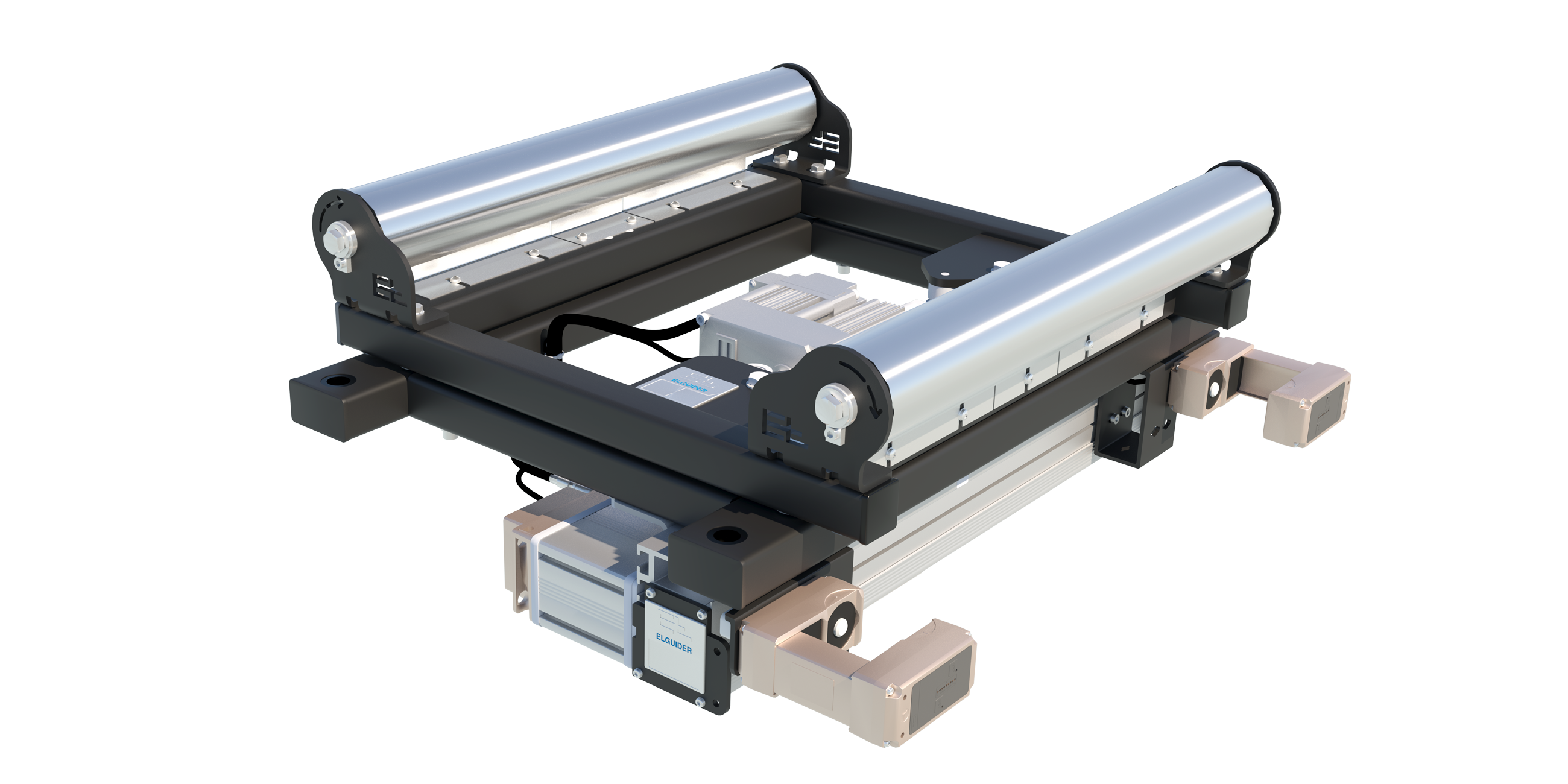

During calendering, the coating on a copper or aluminum foil is compacted between rotating pairs of rollers. A defined line pressure is of crucial importance for the constant thickness of the overall material and a homogenous coating. E+L web guiding control systems ensure accurate web guiding through the calender gap and the web tension control system ensures precise web tension.