Without inspection, no production

Surface inspection systems are now part of the "standard equipment" for production machinery and machines for further processing. The material and the type of processing or the industry are barely significant. Irrespective of whether paper or film/foil, production or processing, for the food, pharmaceutical, battery or hygiene industry, quality requirements have increased everywhere. Often driven by the expectations and require-ments of clients and their customers. This drive has made inspection systems a must in every processing machine. Nowadays, camera systems are the only way to ensure 100% inspection to detect and address defects at an early stage and thus minimize material waste.

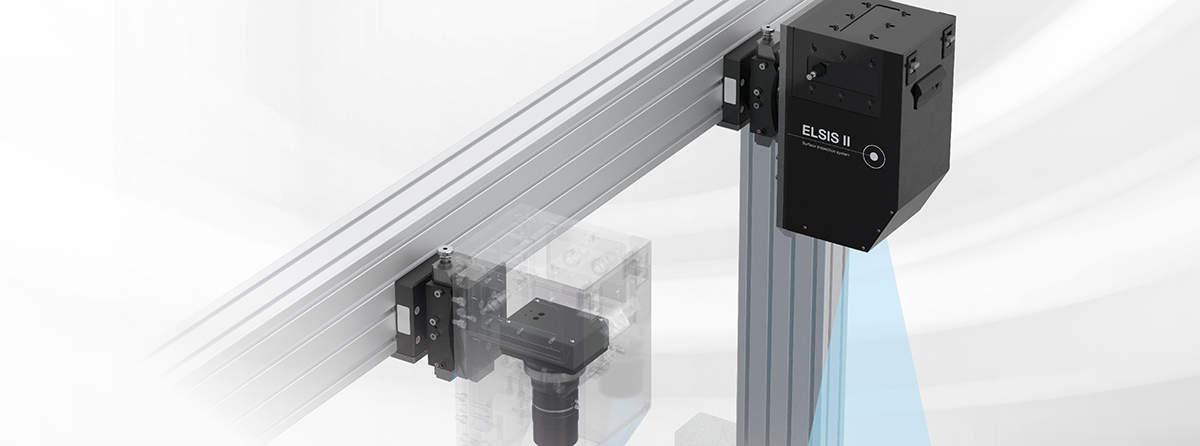

ELSIS inspection systems master this task. Highly sensitive line scan cameras detect any deviation and alert the operator without delay if there is a defect. The automated control of signaling devices such as lamps, horns, marking units and even complete machine control systems can be implemented using the flexible ELSIS I/O control system.

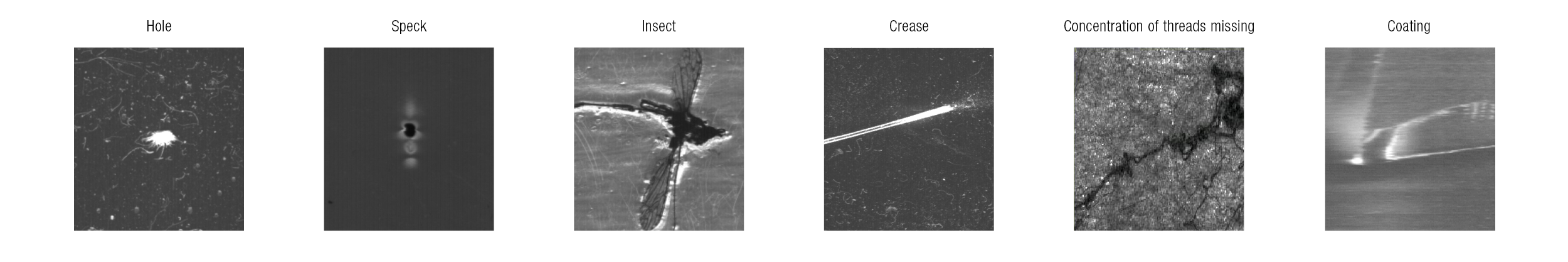

Typical defects

- Description

Function

Examples of typical defects:

- Soiling

- Damage

- Inclusions

- Insects

- Holes

- Bubbles

- Specks

- Chatter marks

- Creases lengthways and crossways

- Doctor blade and streak defects

- Missing coatings

Application

- Inspection of films

- Inspection of pharmaceutical packaging/aluminum

- Coating systems/battery manufacture/metal processing

- Inspection for the non-woven fabric sector

- Inspection for paper manufacture

The significance of the light source

The correct lighting is at the heart of every surface inspection system. The type of lighting, lighting color, intensity and lighting angle often determine whether a defect is visible or remains hidden. In some situations, defects are only detected using transmitted light or combinations of light.

LED light transmitter

- High illuminance

- Different LED colors

- Narrowband spectrum

- Spectrum with long term stability

- Extremely bright

- Modular length

- Can be focused

- Exact, homogeneous line

- Lighting profile can be adjusted via Ethernet

- Long service life

- Constant temperature

- Temperature monitoring

- Robust housing

- Easy assembly