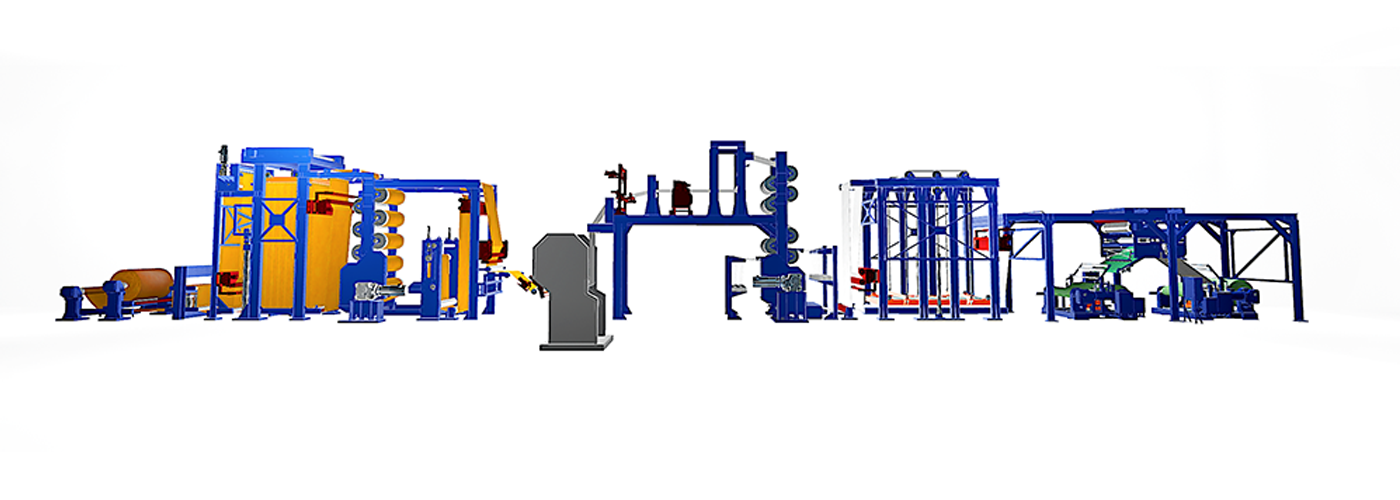

E+L manufactures different customized equipment for upgrade of the existing textile, steel, inner liner and conveyor belt calender lines.

Applications

- Tire & Rubber

- Conveyor belt heavy duty

- PVC

Layout

- Double let-off or shuttle let-off

- Splice press

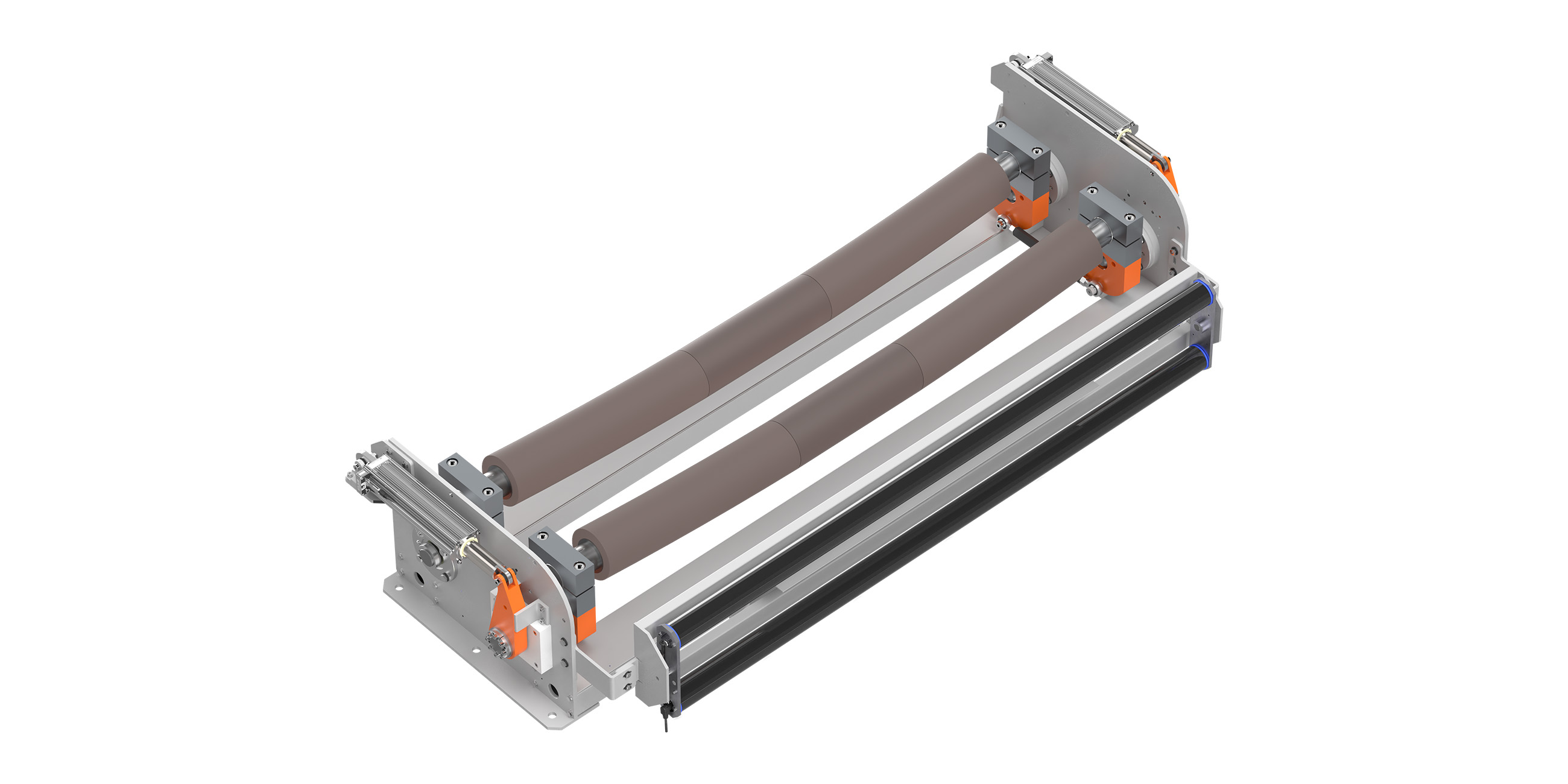

- Different types of pulling units according to different positions along the line

- Hydraulic accumulator for pre and post calender application

- Pre-heating (steam or hot water) and cooling (chilled water) tower drums

- Over tension compensator

- Swivelling feeding conveyor for calender

- Bleeder cord applicator

- Pricking unit

- Cross cutter

- Wind-up: shuttle, dual, dual shuttle or tandem