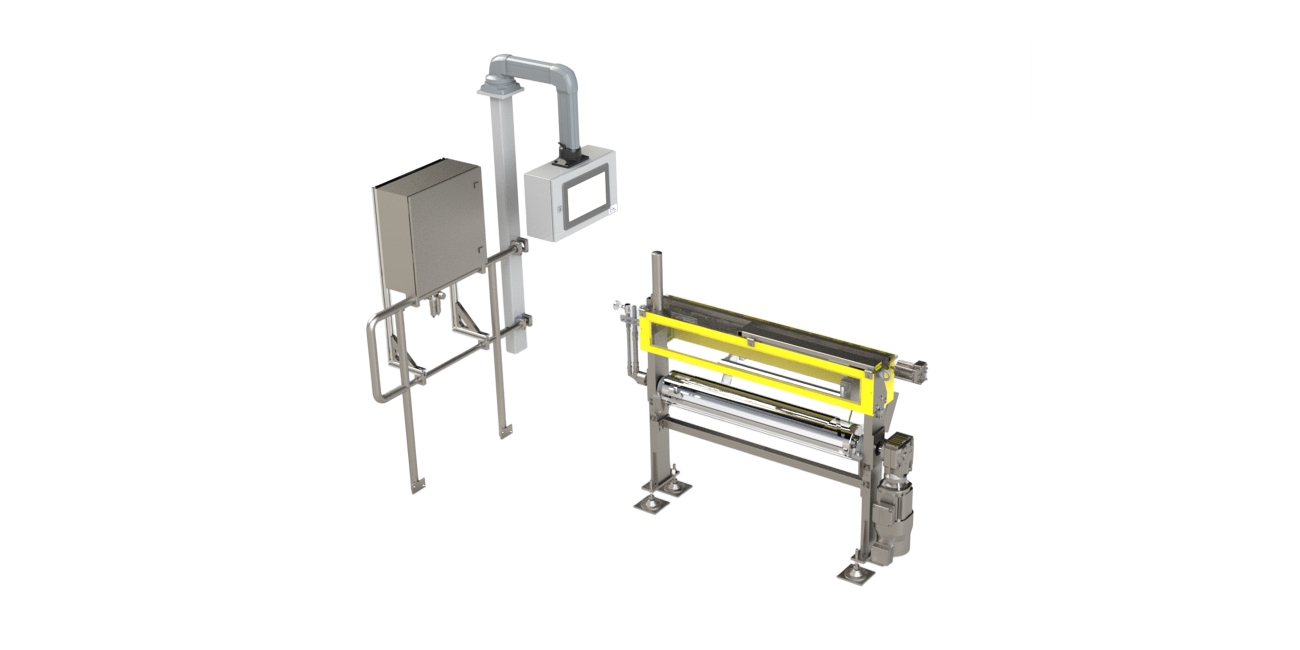

- Description

- Function drawing

Function

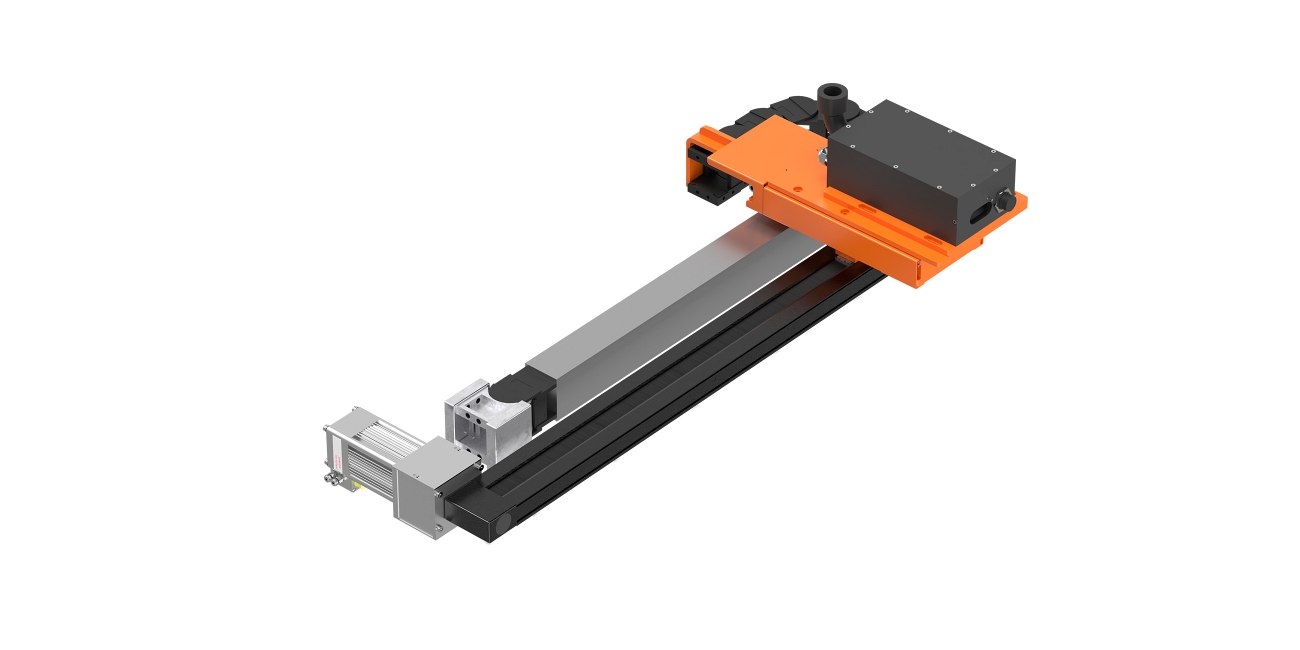

One or more sensors measure the product thickness in one or more locations continuously via differential measurements or reference measurements.

Here, there are various ways in which this system can be used: fixed measurement points or manually/ automatically adopted/traversed measuring points.

Area of use

Systems for the measurement of thickness are mostly used in calender and extrusion lines. EL-THICKNESS systems are highly modular and can be integrated flexibly into production lines.

Application

Thickness measurement systems can be installed in almost any position in roller head lines, calender lines and extrusion lines.

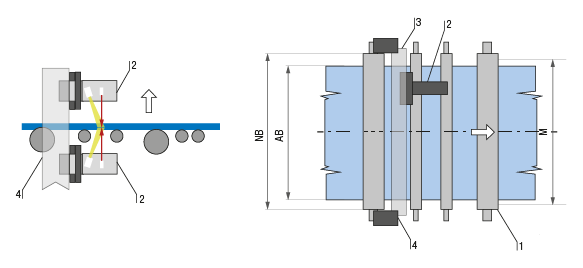

Differential measurement

Legend

AB = Operating width | M = Measuring range | NB = Nominal width | 1 = Guide roller | 2 = Sensor | 3 = Positioning device | 4 = Granite frame

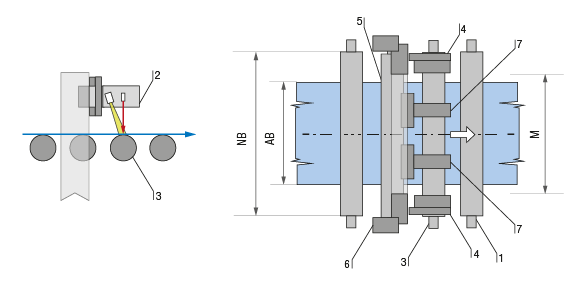

Reference measurement

Legend

AB = Operating width | M = Measuring range | NB = Nominal width | 1 = Guide roller | 2 = Sensor | 3 = Reference roller | 4 = Reference sensors (optional) | 5 = Positioning device | 6 = Frame | 7 = Measuring sensors