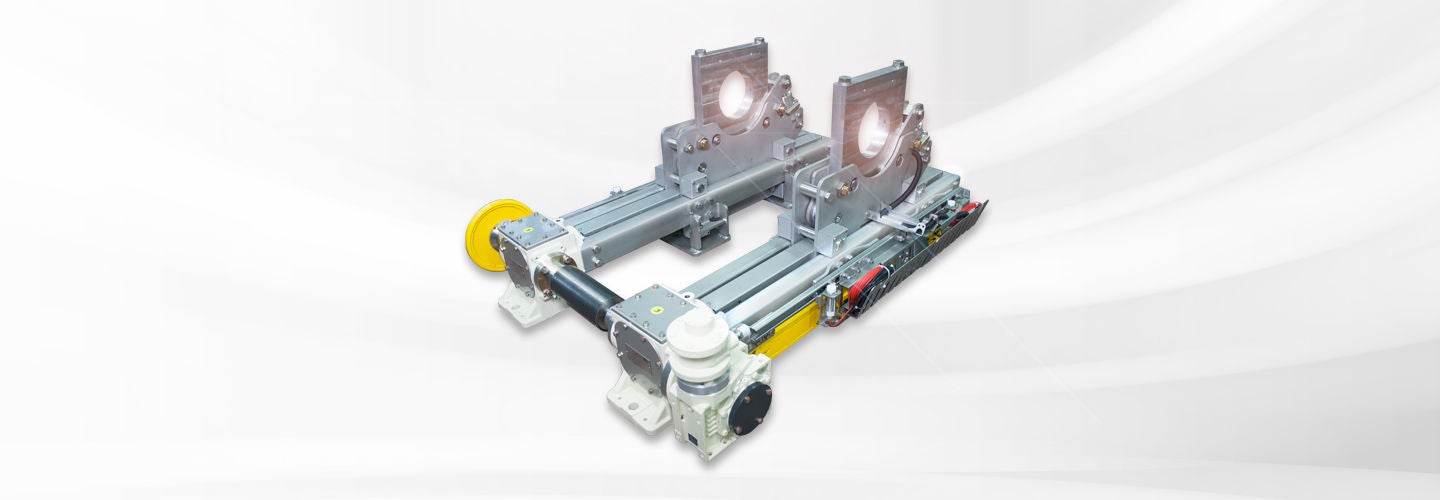

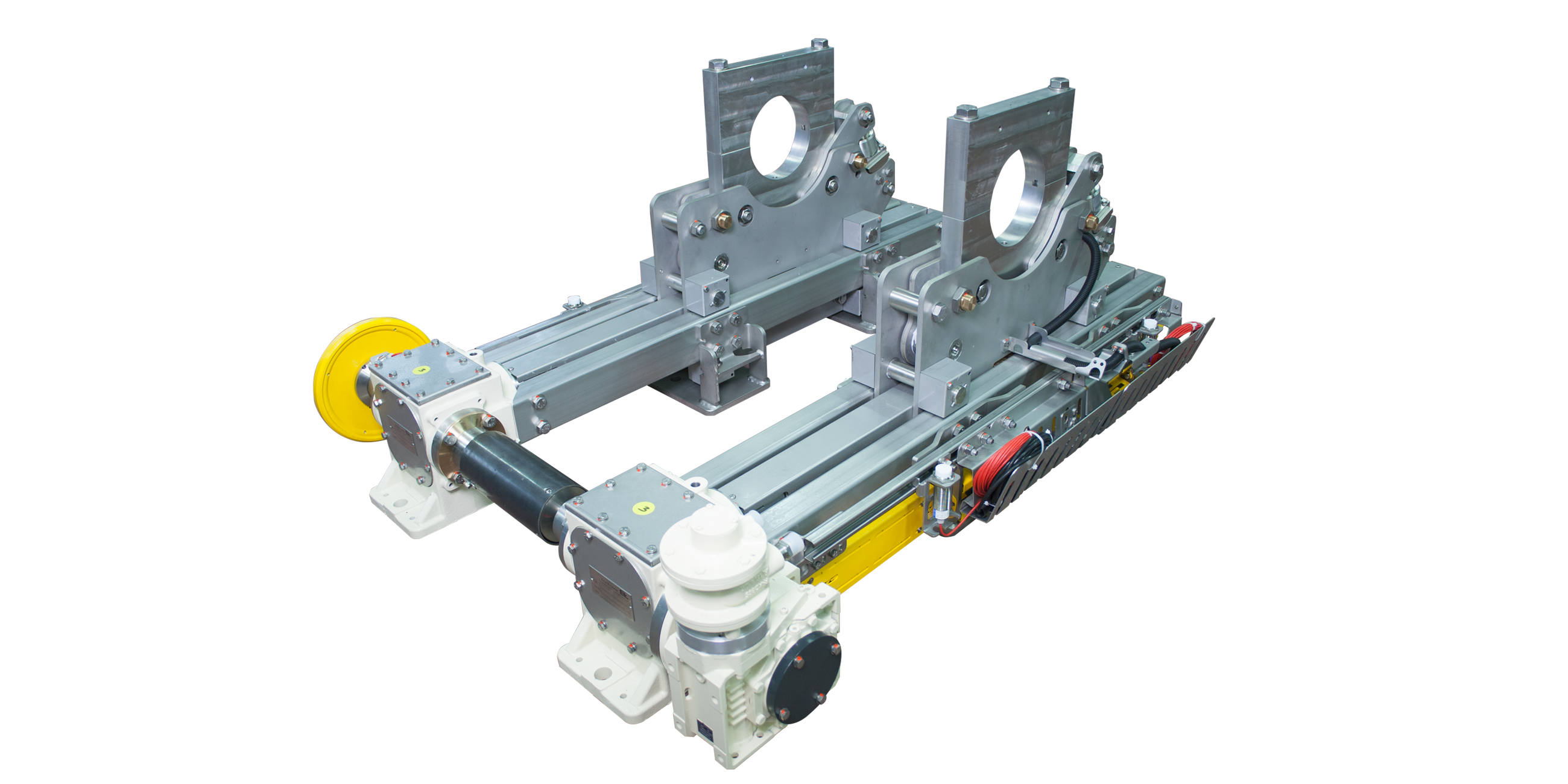

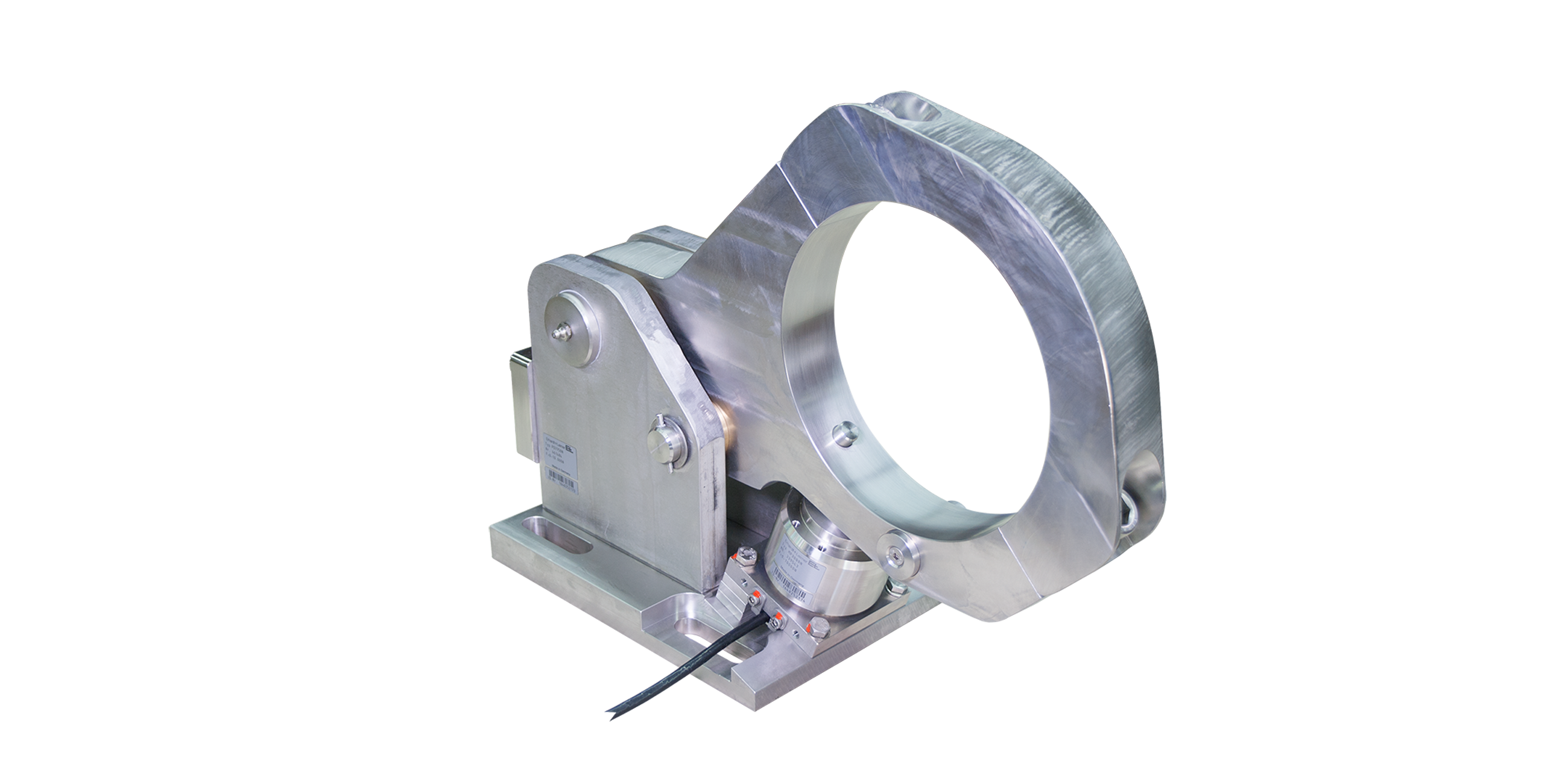

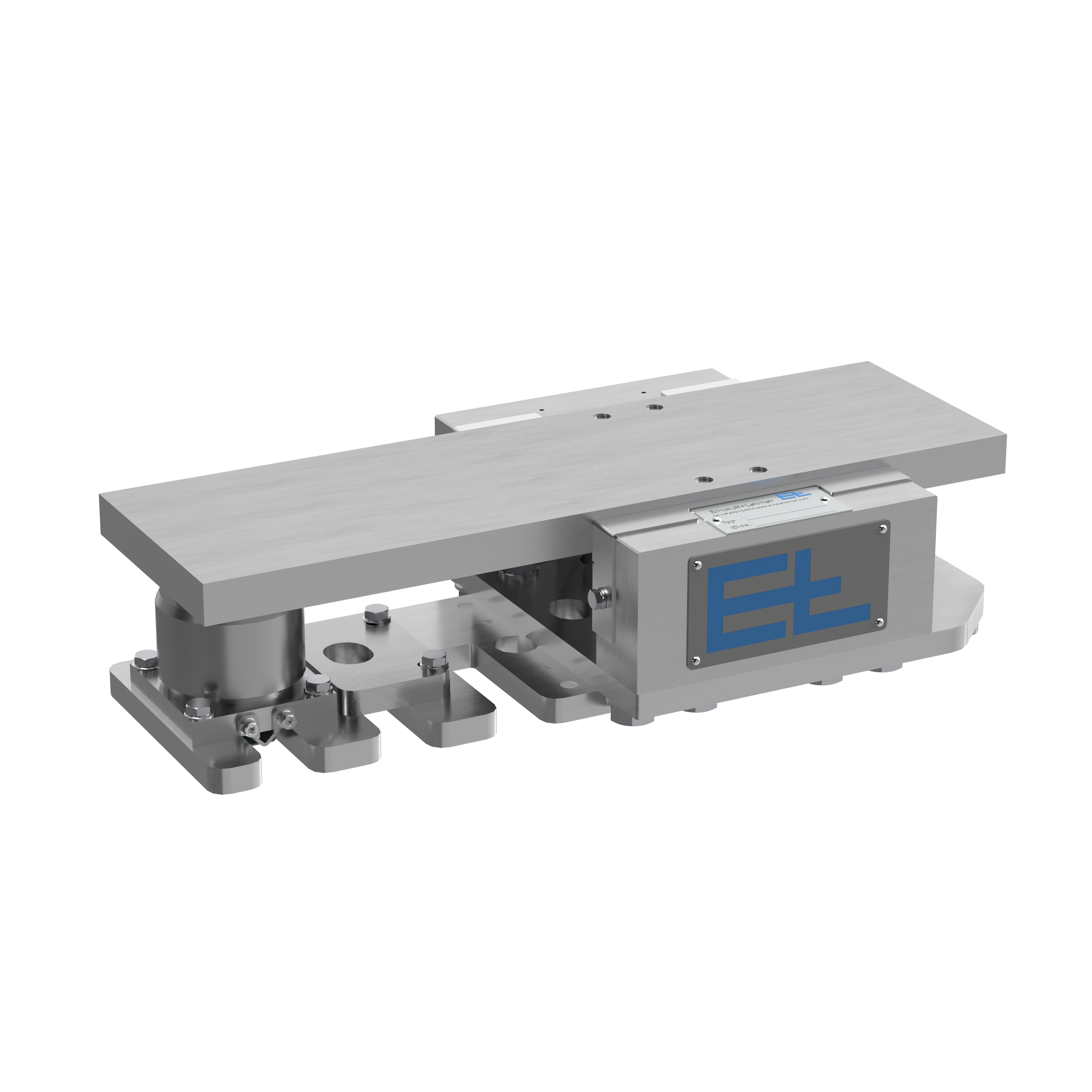

- Description

- Function drawing

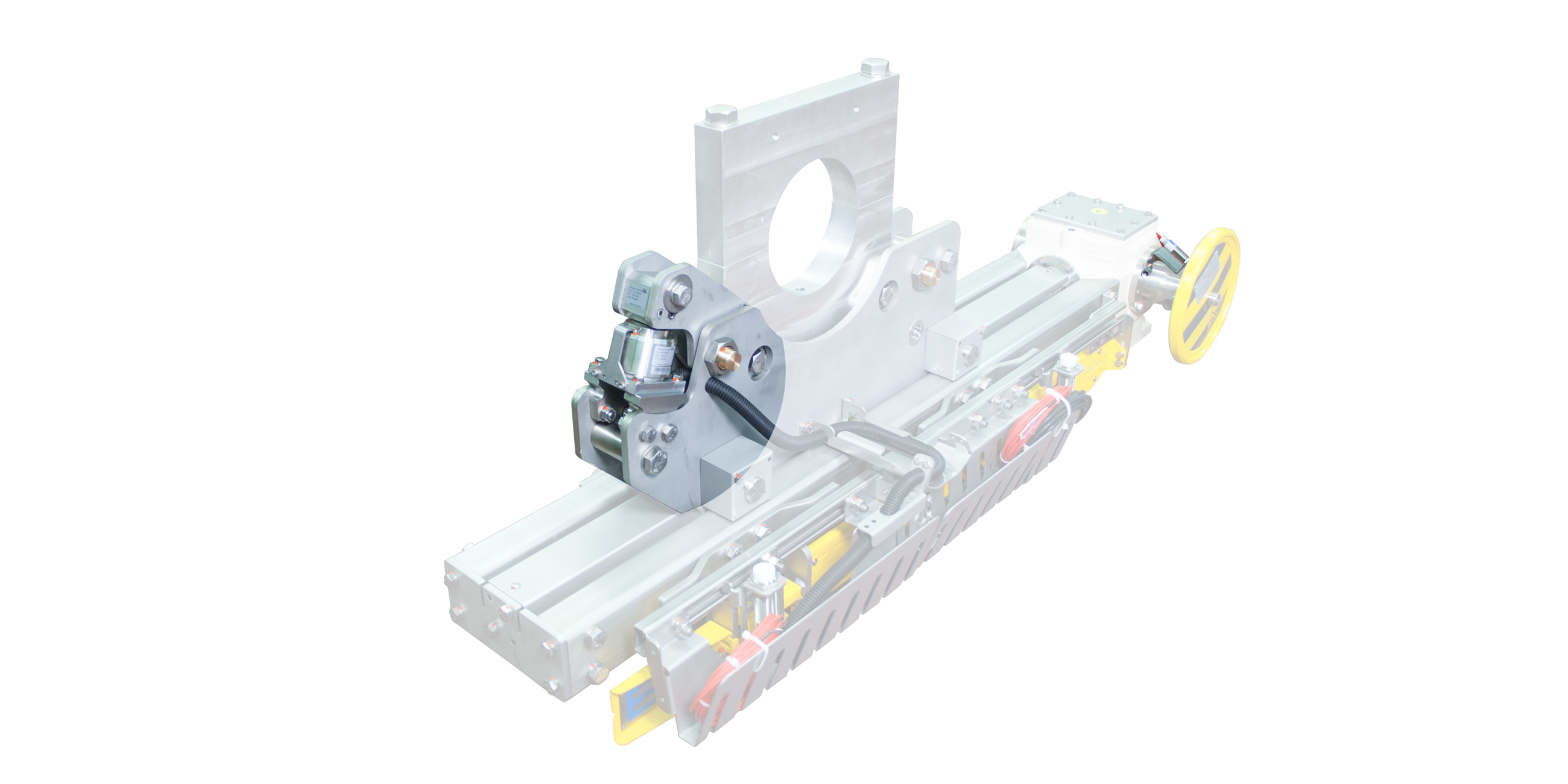

Function

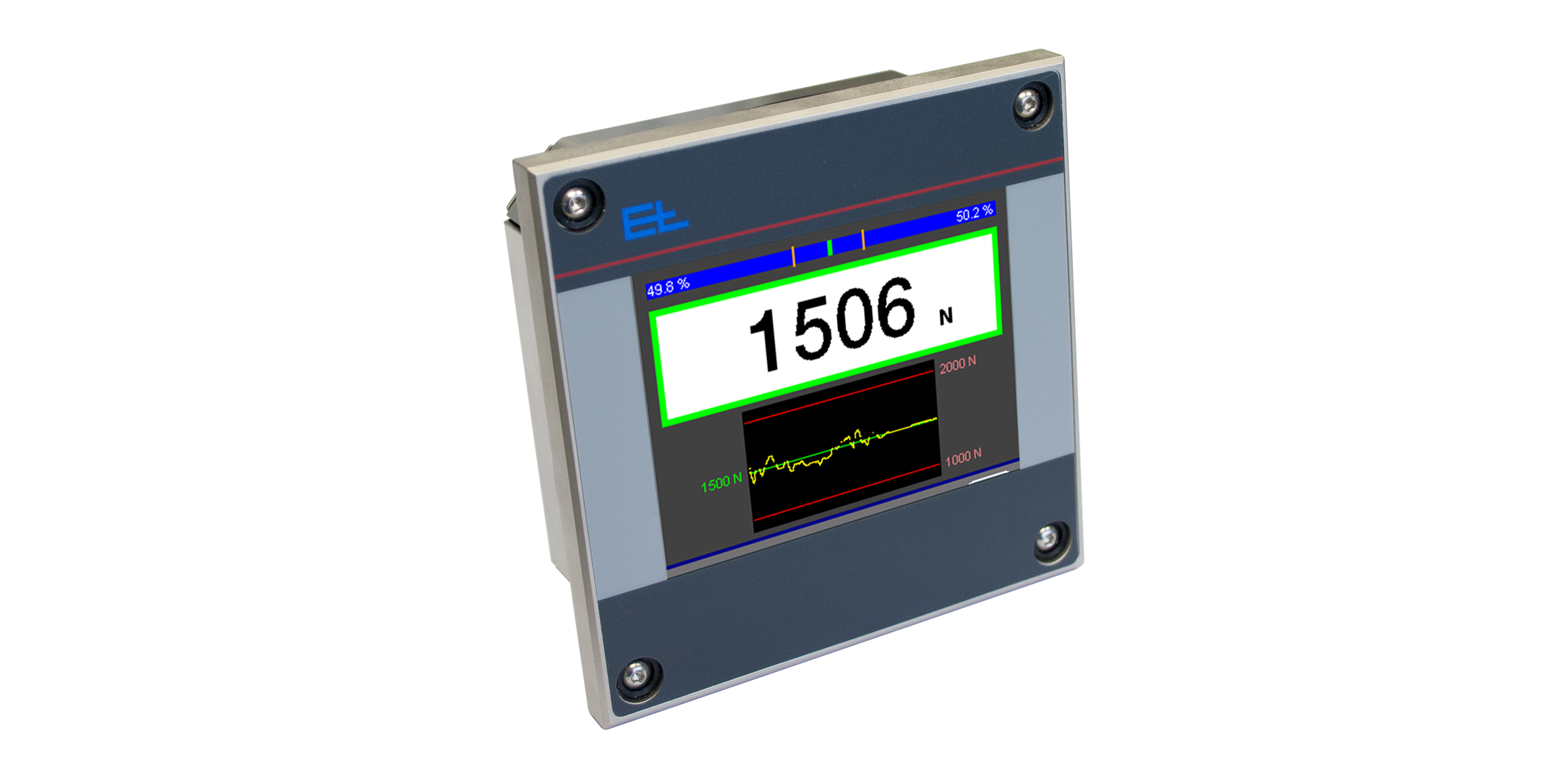

Spindle-type stretcher systems monitor and control the fabric tension of revolving felts. Integrated tension sensors acquire the fabric tension continuously and without delay. A digital three-point controller continuously compares the actual value with the set target value and sends a correction value to the actuating drive, as necessary. The tension on the felt is increased or decreased via the spindle-type stretcher.

Area of use

The spindle-type stretcher system is used in the press section of a paper machine.

Application

Spindle-type stretcher systems can be freely mounted in terms of position. Wrapping of 180° is desirable for the stretch roller. The adjusting plane of the spindle-type stretcher should be positioned in the bisecting line between the infeed and outfeed. Wrap angle compensation needs to be incorporated if the overall wrap around the stretch roll is smaller than 150°.

Legend

FB = Felt width | LE = Distance to bearing center | FB = Web tension | FS = Actuating force | FG = Weight, stretch roller | FR = Resulting web tension | 1 = Spindle tension | 2 = Infeed roller | 3 = Outfeed roller | 4 = Force sensor | 5 = Outfeed roller | A-A = Web tension distribution | s = Stretching path | α, β = Infeed and outfeed angle