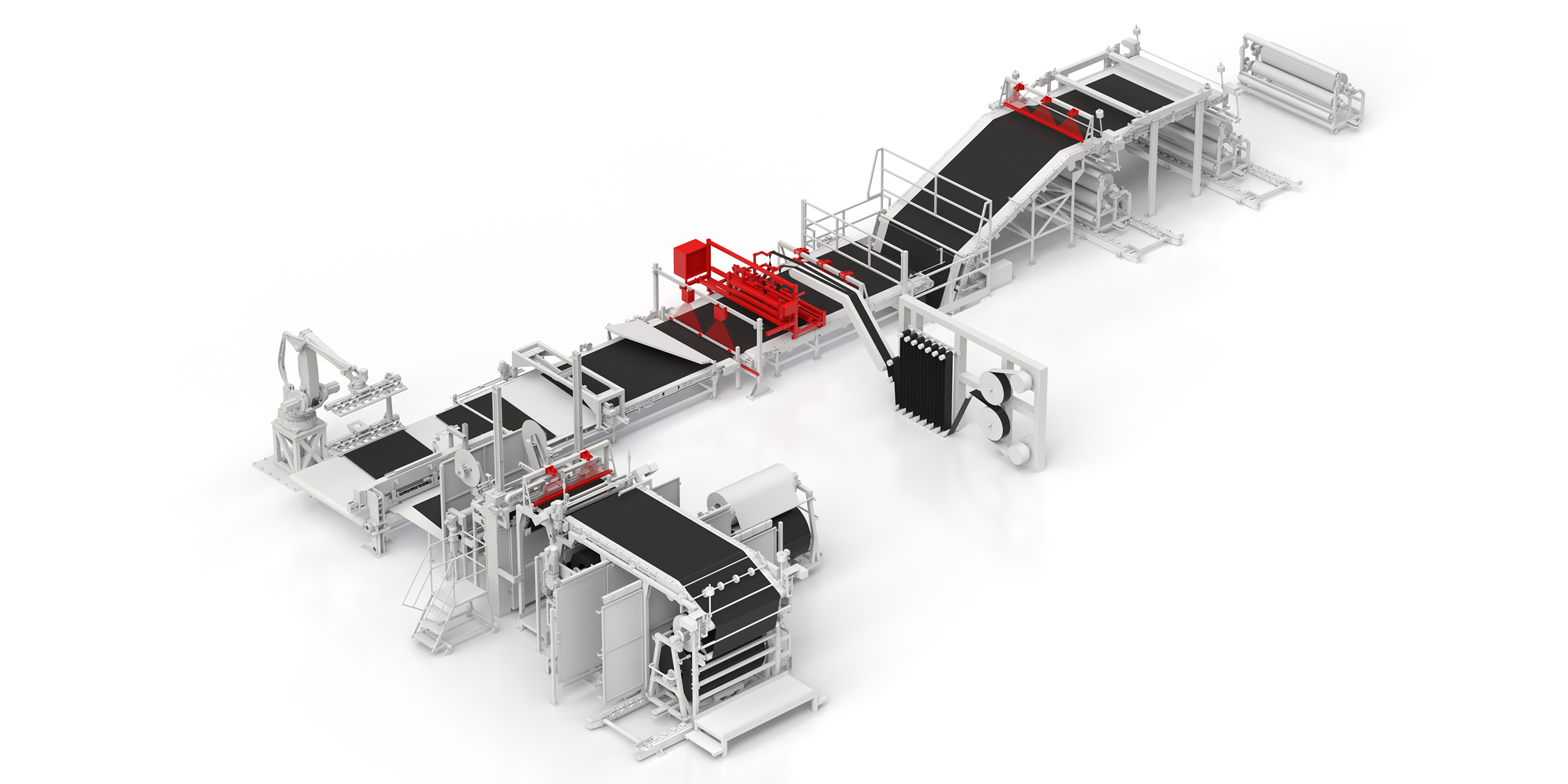

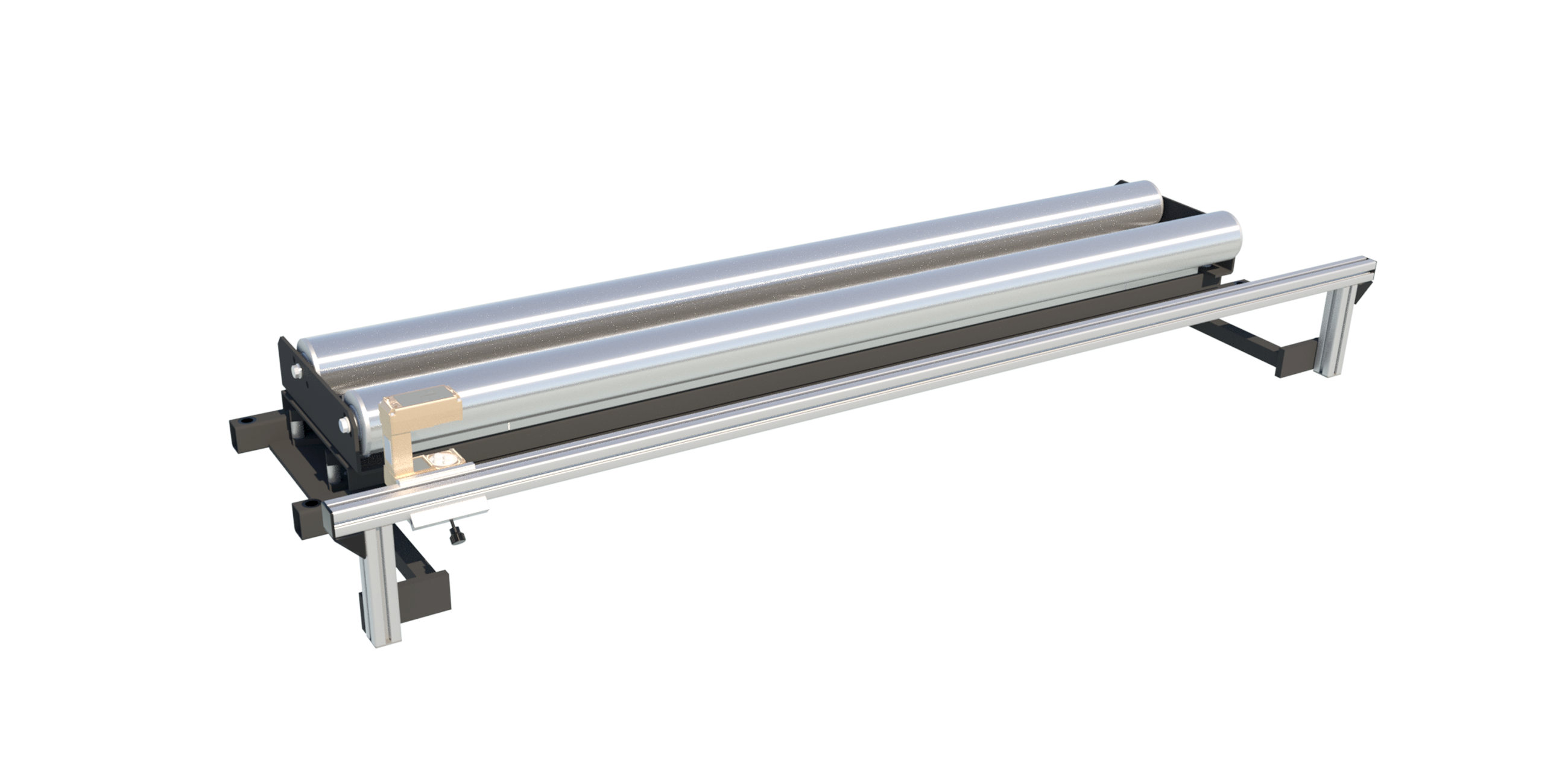

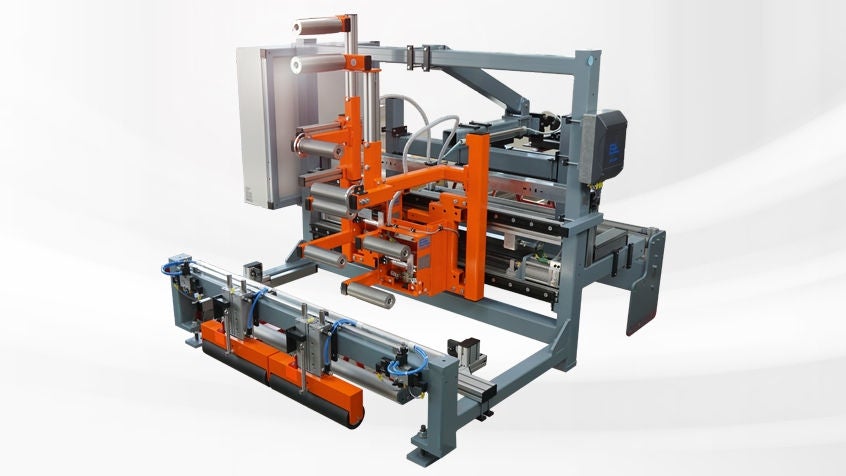

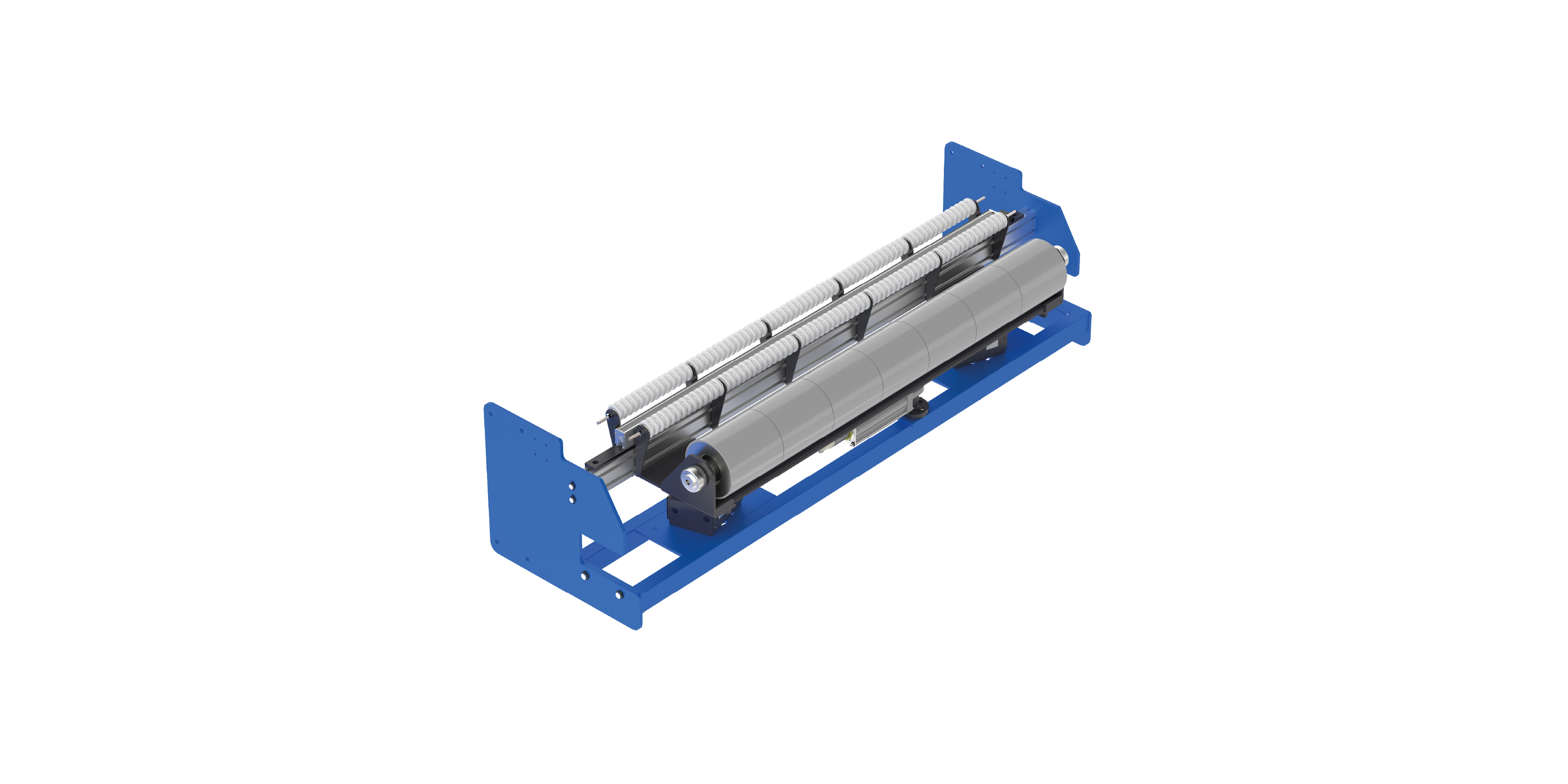

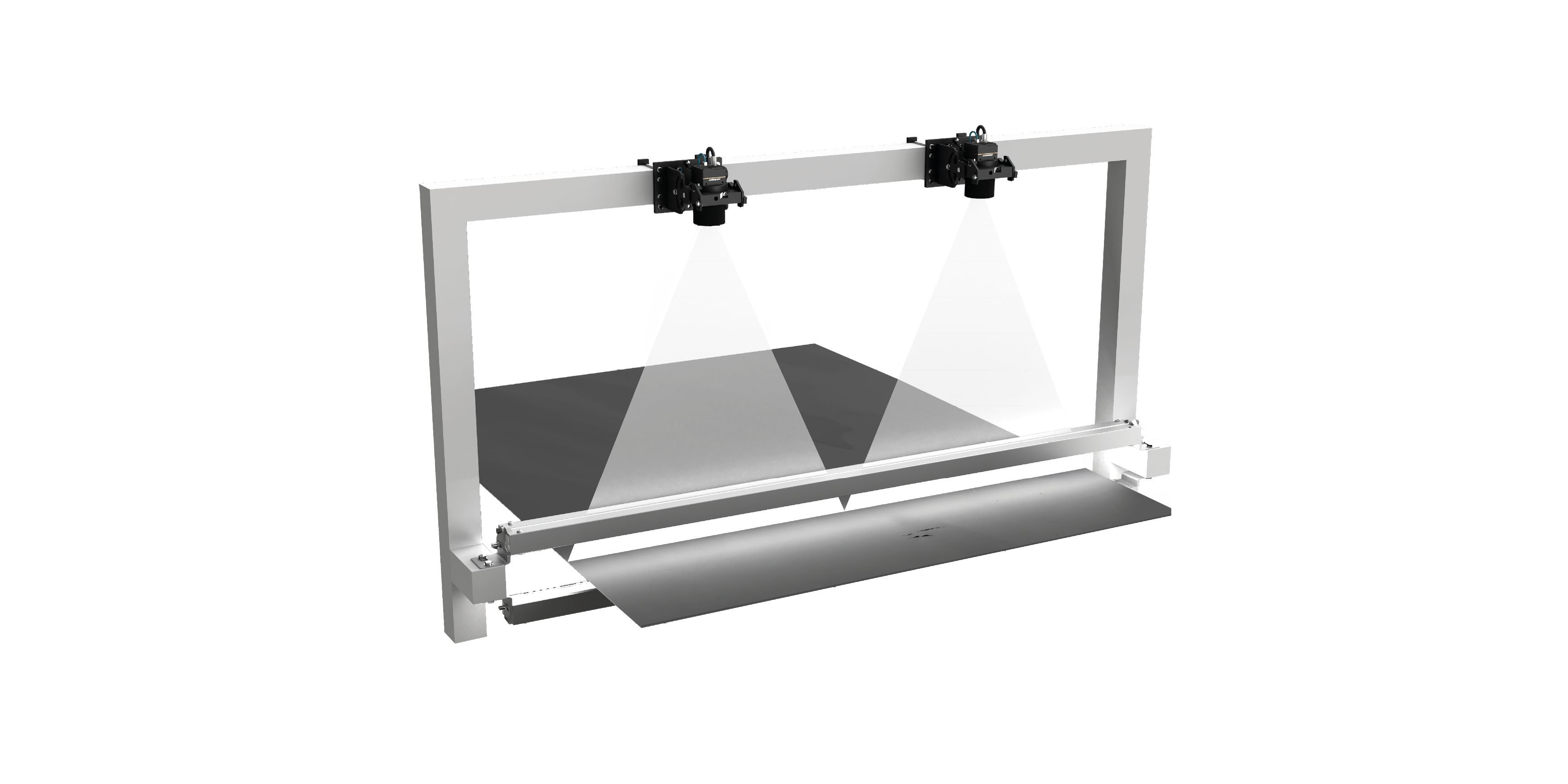

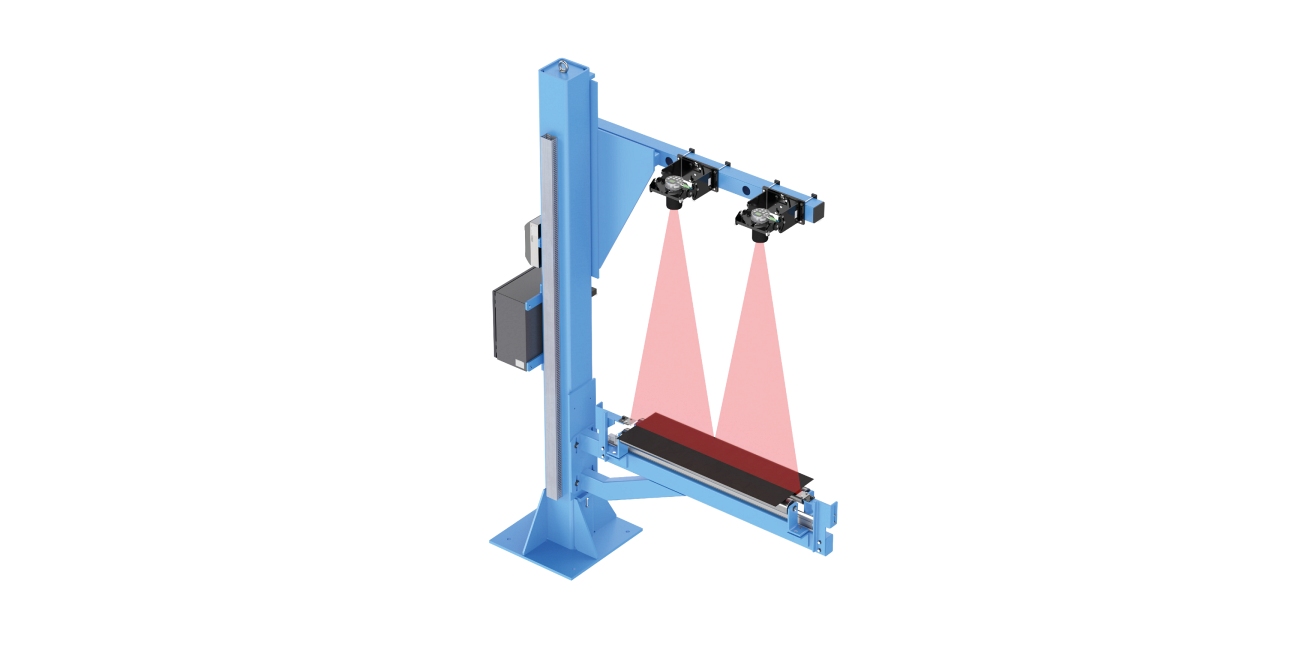

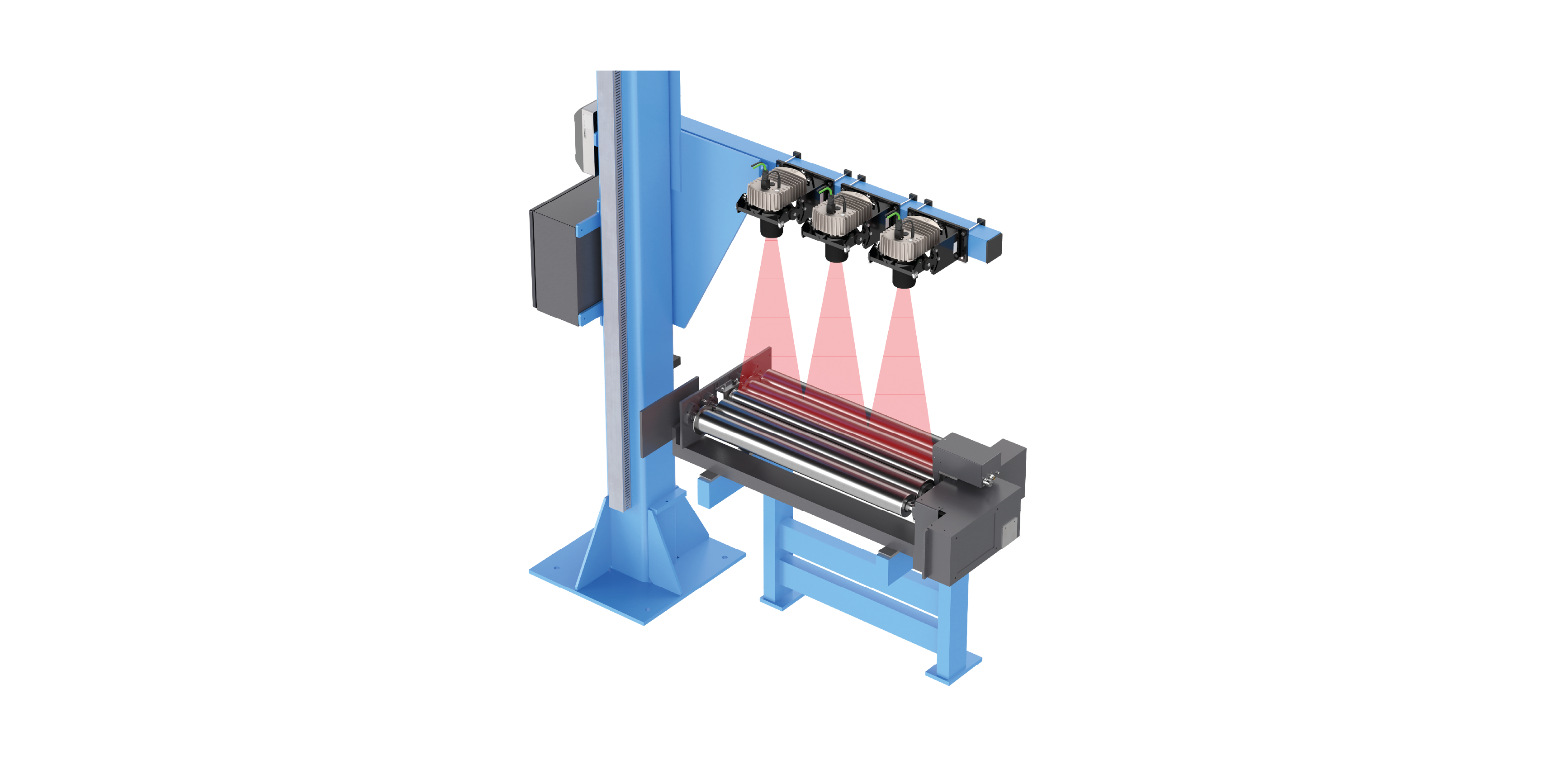

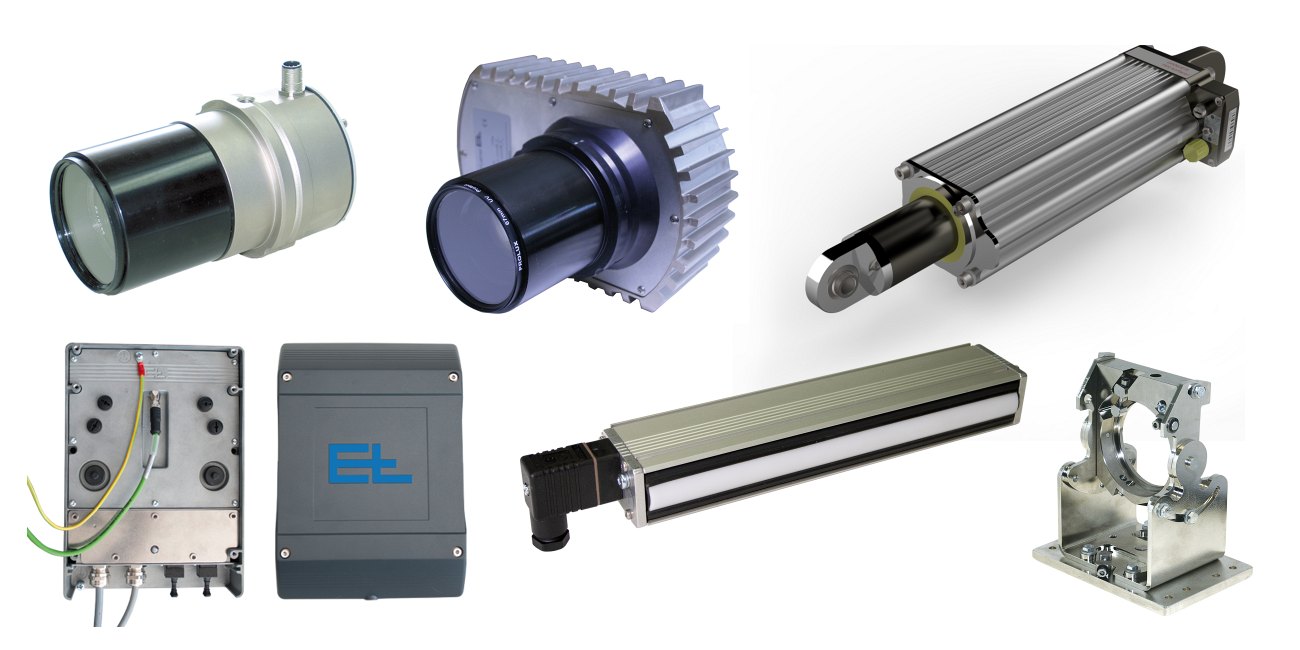

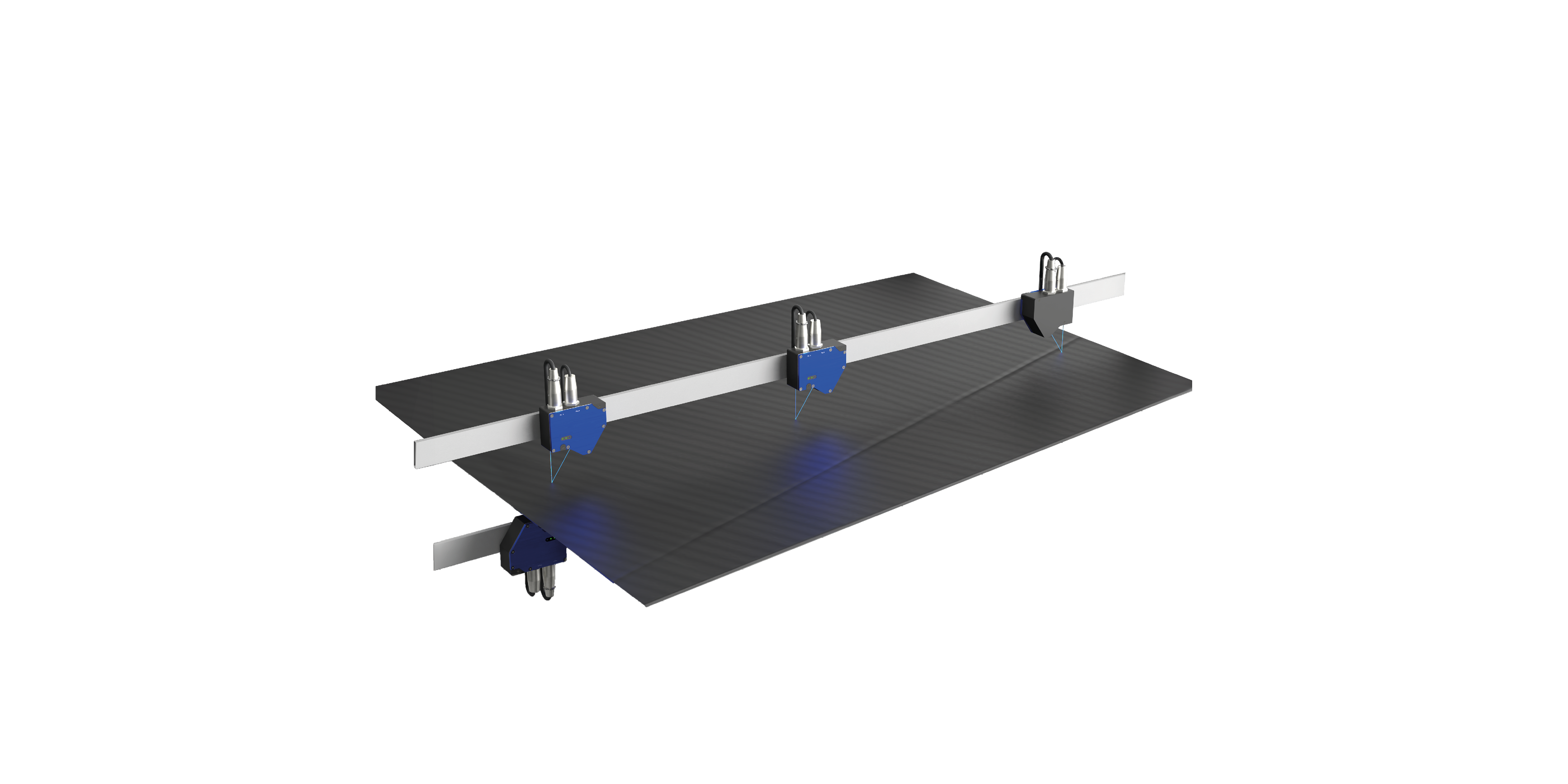

On textile cord cutting lines, the material manufactured previously on the calender is cut at a defined angle and joined together again to provide maximum stability in the finished tire. E+L supplies all the components to keep the webs in position and to laminate them with other materials, as well as measuring systems for monitoring the width or splices. In this way the highest quality demands are met.