Application

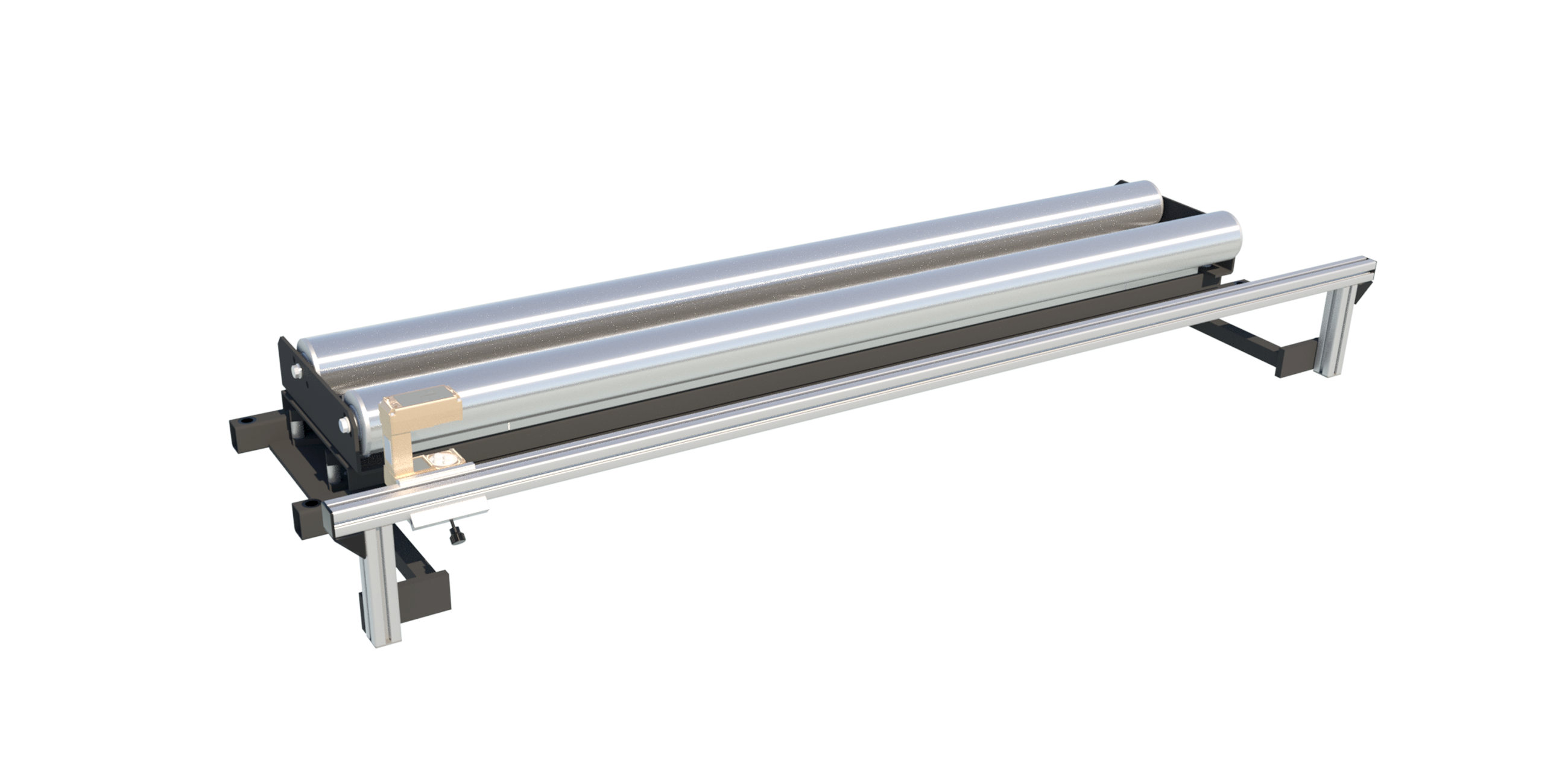

- Adaptability to multi cassettes and multi-liner material (textile/polyester, polyethylene, etc.) used in tire-building machines

- This equipment is intended to restore the liner alignment throughout each wound from core to core

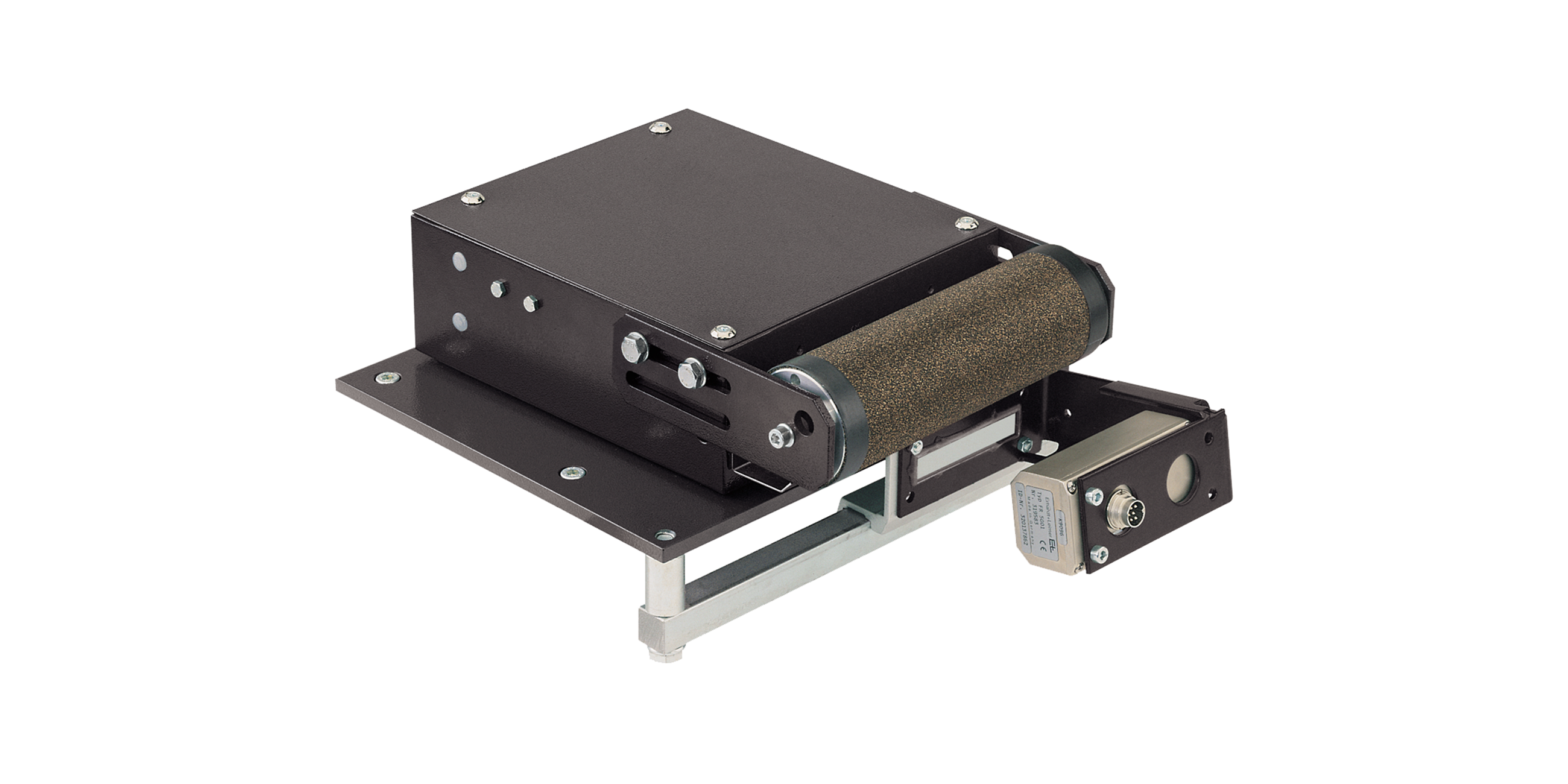

- Equipped with ELROLLER SRB: compact steering roller system with one or two rollers for different wrap angles and wear-free, brushless drive technology for highest positioning accuracy and control dynamics; integrated digital controller with position, speed, and current controller for highest quality positioning

- Integration of ELTENS load cells PD 21 because tension is a key factor for a correct liner conveying at each tire building process

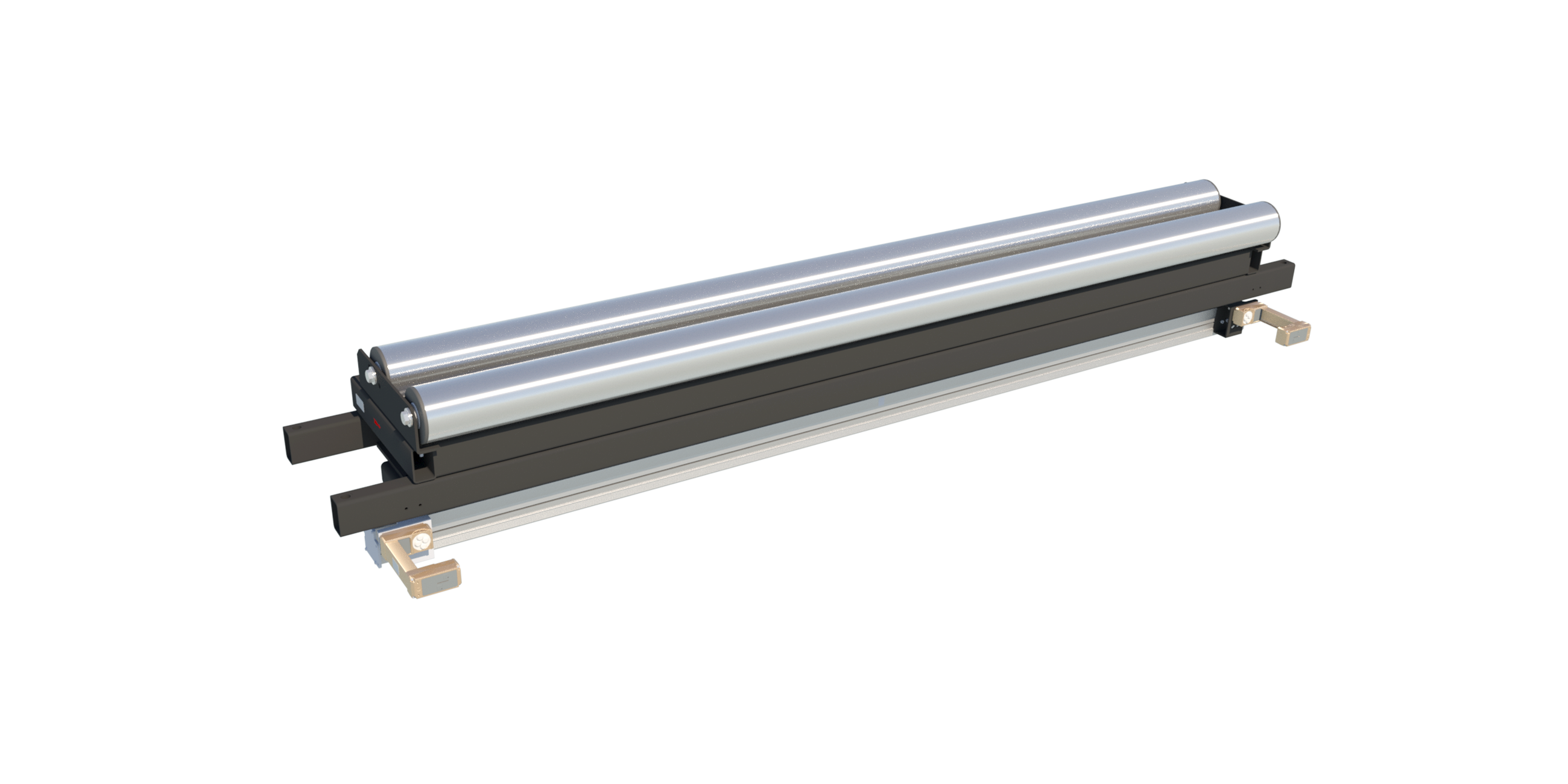

Scrap rubber removal function

- The scrap removal task can be: semi-automatic (via safety footswitch – light scrap) or automatic (from command station in a safe area – heavy scrap)