- Description

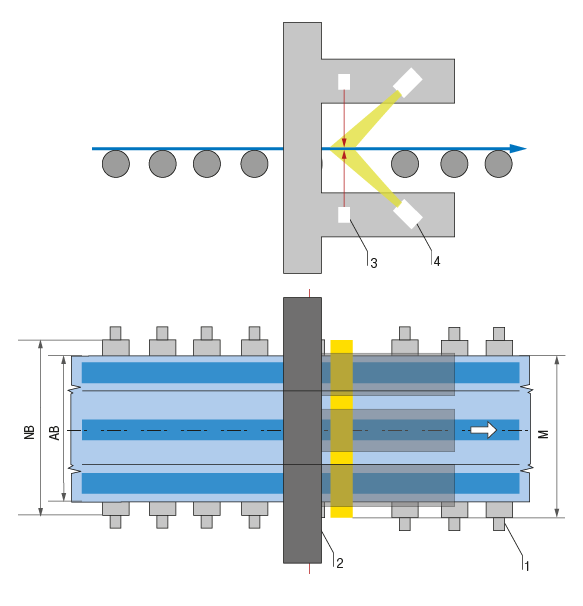

- Function drawing

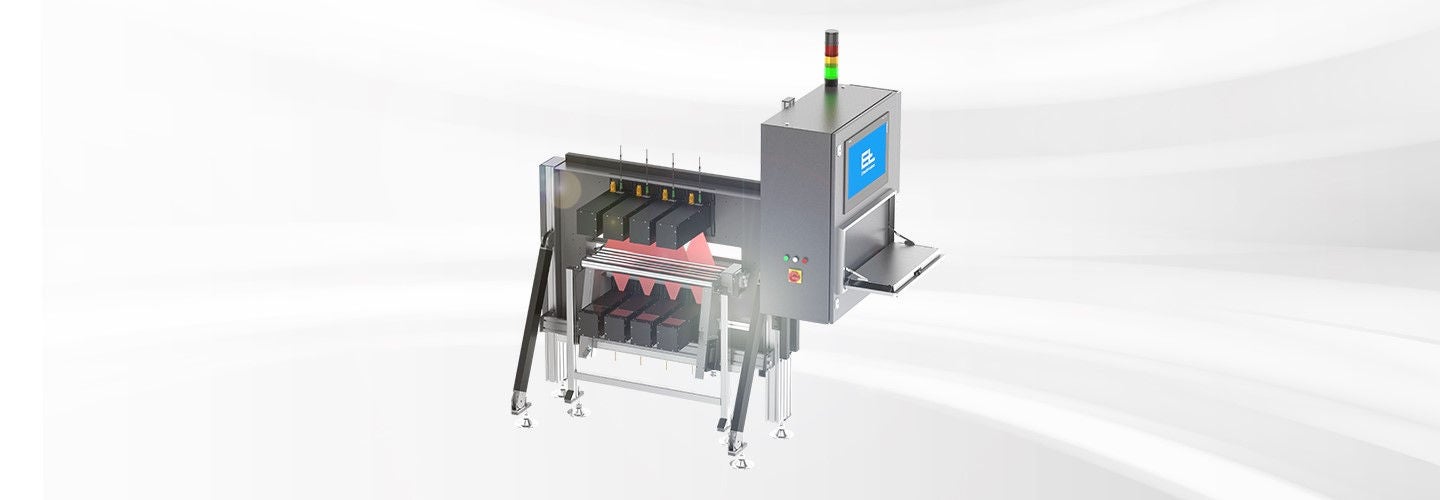

Function

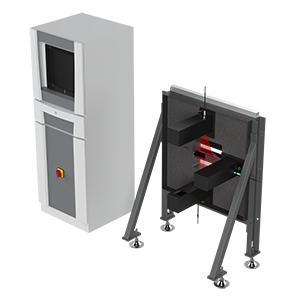

Light section sensors measure the external geometry of complex rubber strips on three or four sides. The granite frame, on which the sensors are mounted, offers high thermal stability and reduced vibration for highly accurate profile measurements.

Area of use

High-accuracy online profile measurement is used primarily in extrusion systems for the continuous inspection of treads and side walls, as well as inner liners. In the hot area, the profile measurement is used for production control to detect deviations from the specification as early as possible and alert the PLC. In the cold area, the profile measurement system is used for quality control and documentation.

Application

The EL-TRISCAN LS system for profile measurement is used in the extrusion line immediately after the extruder for process control and/or preferably at the end of the cooling line for quality assurance. The granite frame reduces the thermally induced expansion many times over.

Legend

1 = Guide roller | 2 = Profile measurement | 3 = Laser line | 4 = Matrix camera| M = Measuring range | AB = Operating width | NB = Nominal width

Possible applications