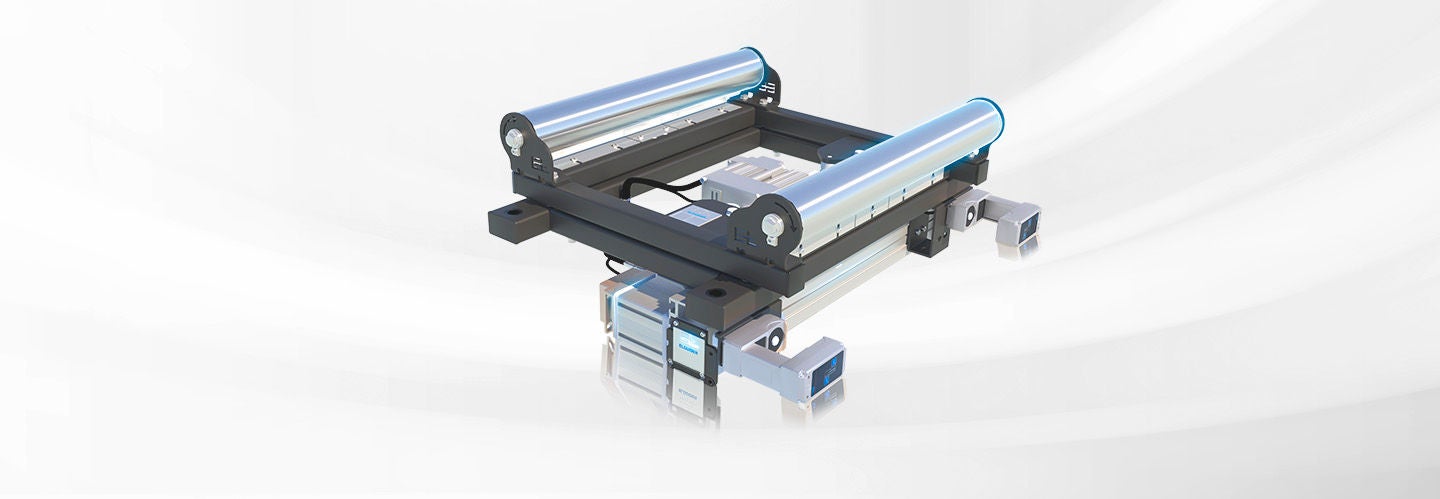

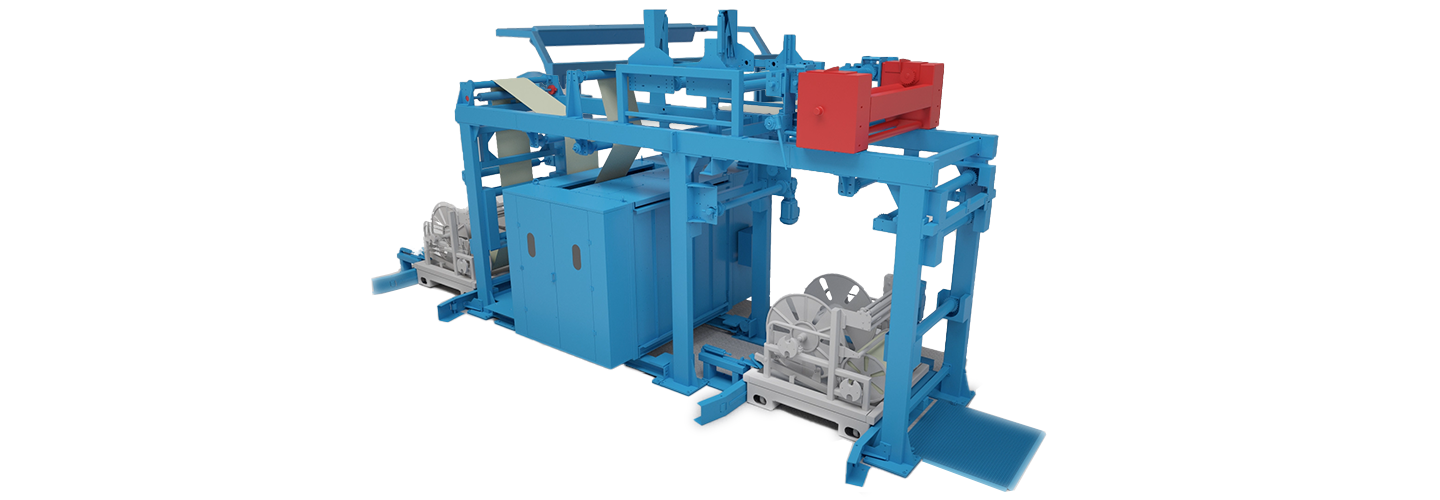

The automatic cleaning system is designed for liner cleaning used on the calendar or extrusion lines to ensure uninterrupted production and high quality. A lot of different solutions are available to adapt the machine for each bobbin and cassette.

Layout

- Inlet and outlet liner stock

- Automatic material threading

- Driven beating roller

- Driven brushes

- Adjustable air blade

- Each group is equipped with one suction system

- Automatic material run out detection

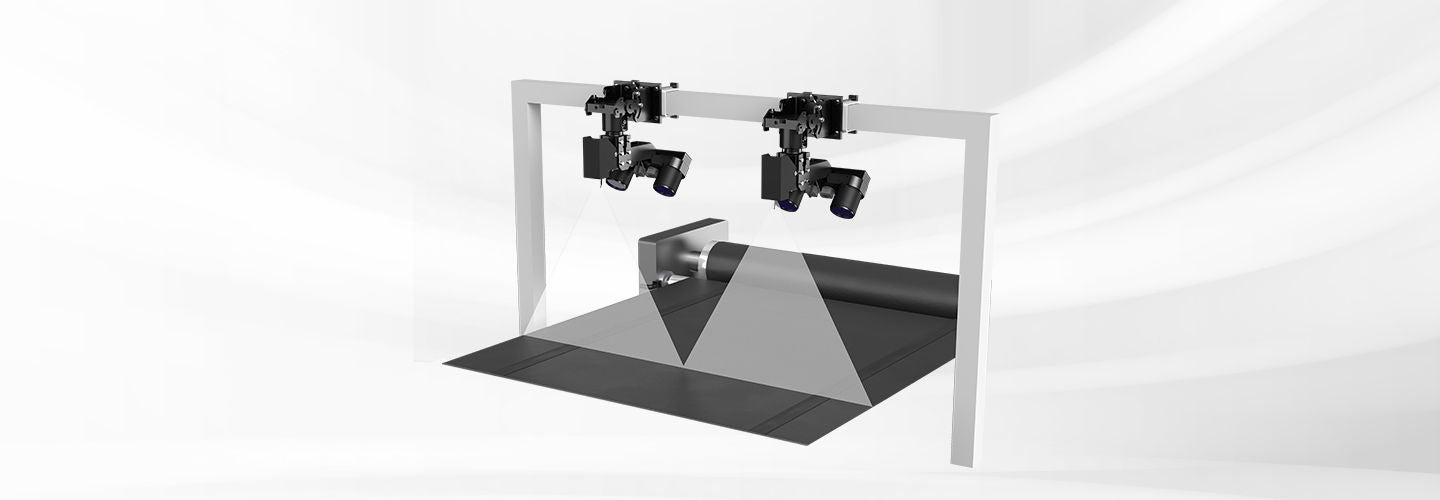

- Residual rubber monitoring and detection

- ELGUIDER Web guiding system

- Edge defect detection

- Liner material spreading

- ELTENS Tension control with automated run out knot sensor

- Automatic forward of unwind/rewind cores

ELCLEAN

- Modular machine which works with a mix of brushes, beaters and air blades in order to clean and remove the dust from the material

- Cleaning of both sides of the web simultaneosuly

- No distortion of the web

- Low operation and service costs