Automation & Vision Systems

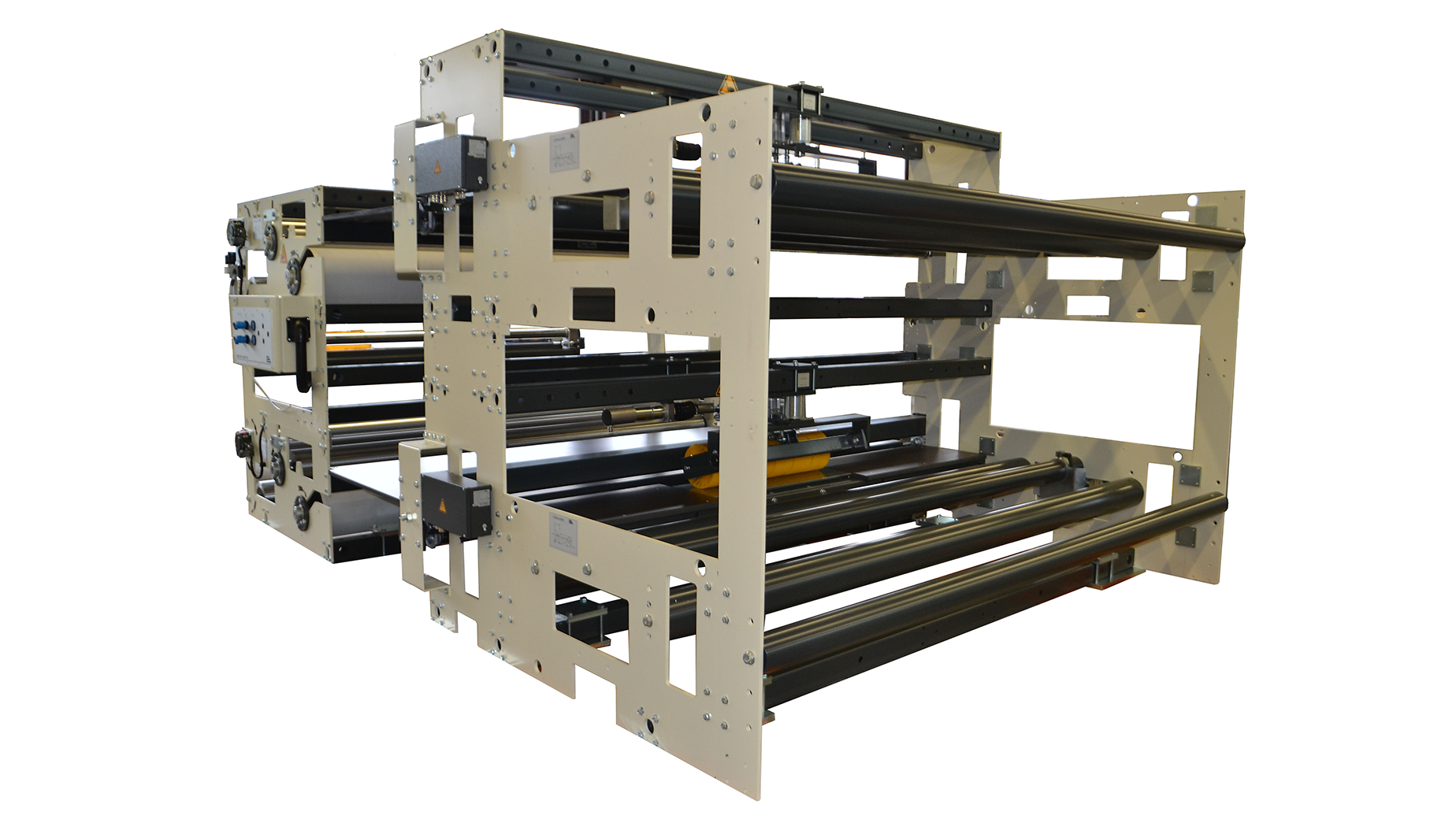

Bridge web guiding system CorrAligner

-

- /content/dam/erhardtandleimergmbhprogram/products---spare-parts/product-types/web-guiding/bridge-guiding/CorrAligner.png

- Description

- Technical Data

Your advantages

Description

- Reduced paper waste

- Reduced trimming / max. width utilization

- Increase in productivity in corrugated cardboard production

- Improved quality of the finished cardboard boxes

Description

- CorrAligner web guiding system for web center guiding of one-sided corrugated cardboard after unlooping on the bridge

- Bridge web guider in frame design with wear-free, brushless drive technology for highest positioning accuracy and control dynamics

- With FE 45 infrared wide band sensor for fast format changes and width measurement

- Can be networked with other control systems via Ethernet in a star or line topology

- Optionally with integrated fieldbus interface Ethernet/IP

- Simple service and diagnostics options via web-based management tools based on a standard web browser

| Max. machine speed | 500 m/min |

| Max. paper width | 3300 mm |

| Max. paper weight | ~800 g/m² for each single-faced web |

| Positional accuracy after the system | +/- 1 mm |