More precise cutting with AI: Next generation web cutting systems

The act of cutting a textile surface is as ancient as its construction. Like all continuous processes, significant savings can be achieved here through optimized workflows – and also thanks to artificial intelligence.

18.02.2026

Cutting is a key production step in the industrial manufacture of textile webs. This article describes modern web cutting systems and shows how precise sensors, intelligent cutting devices, and artificial intelligence can reduce material waste, increase process reliability, and lower production costs. Using typical applications - fixed use width, minimum and exact edge trimming, center cuts, and tube slitting - it outlines technological requirements, savings potential, and practical solutions. The article is aimed at users and decision-makers in textile finishing who want to make cutting processes more transparent, efficient, and reliable.

Producing a textile surface is one thing - however, its subsequent processing frequently necessitates a web cutting system during finishing. The reasons for this are as diverse as the textile itself:

- Fixed use width (especially for coatings or laminations)

- Minimum edge trimming (efficient material use)

- Precise edge trimming (for digital printing)

- Center cut (cost savings during production)

- Tube slitting (for tubular fabric)

Every technology has its unique characteristics. But they all have one thing in common: you can save a lot of money if you can optimize the respective cutting processes and present them transparently.

A cutting system always consists of two components:

- Sensors

- Cutting device

The sensors identify the position where the fabric must be cut. The cutting device is subsequently positioned precisely at the location of the cut via a control unit and support beam. This moves the focus away from traditional cutting techniques to systems that already use artificial intelligence to ensure an optimal result when dividing the web. Cutting tools can be equipped with circular blades (with or without a spring-mounted bottom blade), with powered top and bottom blades (each partially horizontally spring-mounted) or with so-called bowl blades, depending on which application and which textile surface is present.

The following article examines the various aspects of cutting fabric more closely, always keeping the optimal cutting edge in mind:

Fixed use width

Depending on the coating or lamination width, it is crucial to precisely adjust the web width to the machine specifications. Each centimeter that does not match the coated or laminated web width can result in complaints or incur high costs. Therefore, it is important to adjust the use width as precisely and easily as possible. Ideally, the position of the blade can be connected to a current data collection (e.g. via EL.NET), which makes the entire process transparent for all parties involved. This includes the machine operators as well as the technologists or even the customers.

Fig. 1: Edge cut with fixed use width "x"

Fig. 1: Edge cut with fixed use width "x"

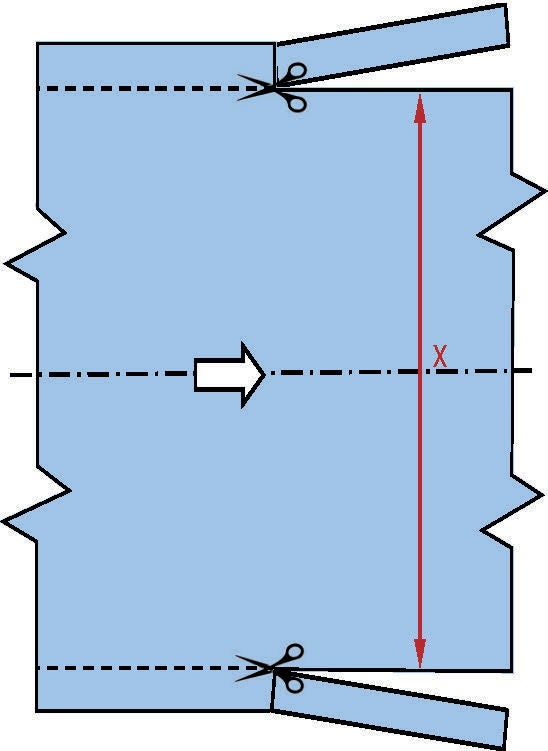

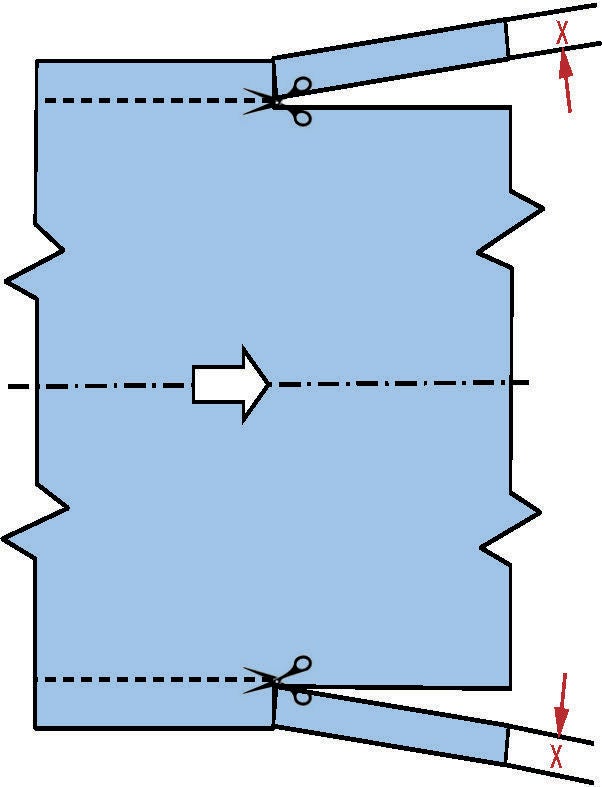

Minimum edge trimming

In continuous processes, every centimeter counts. Particularly when the emphasis is on maximizing the use width, it is crucial to minimize the edge trimming. In this scenario, the sensor system and cutting tool must work together perfectly. A wide band infrared edge sensor detects the edge of the web with a precision of 0.1 mm, even with highly transparent textile web edges. The cutting blade is precisely adjusted based on the impulse, ensuring consistently minimal edge trimming.

Fig. 2: Edge cut with minimal edge trimming

Fig. 2: Edge cut with minimal edge trimming

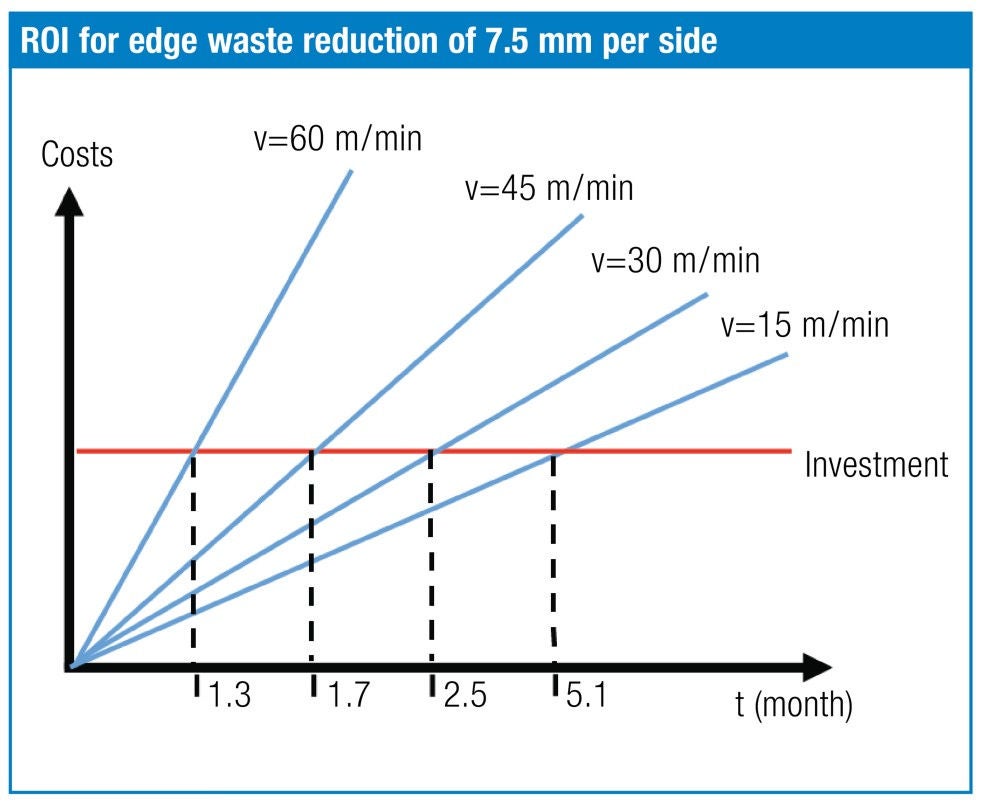

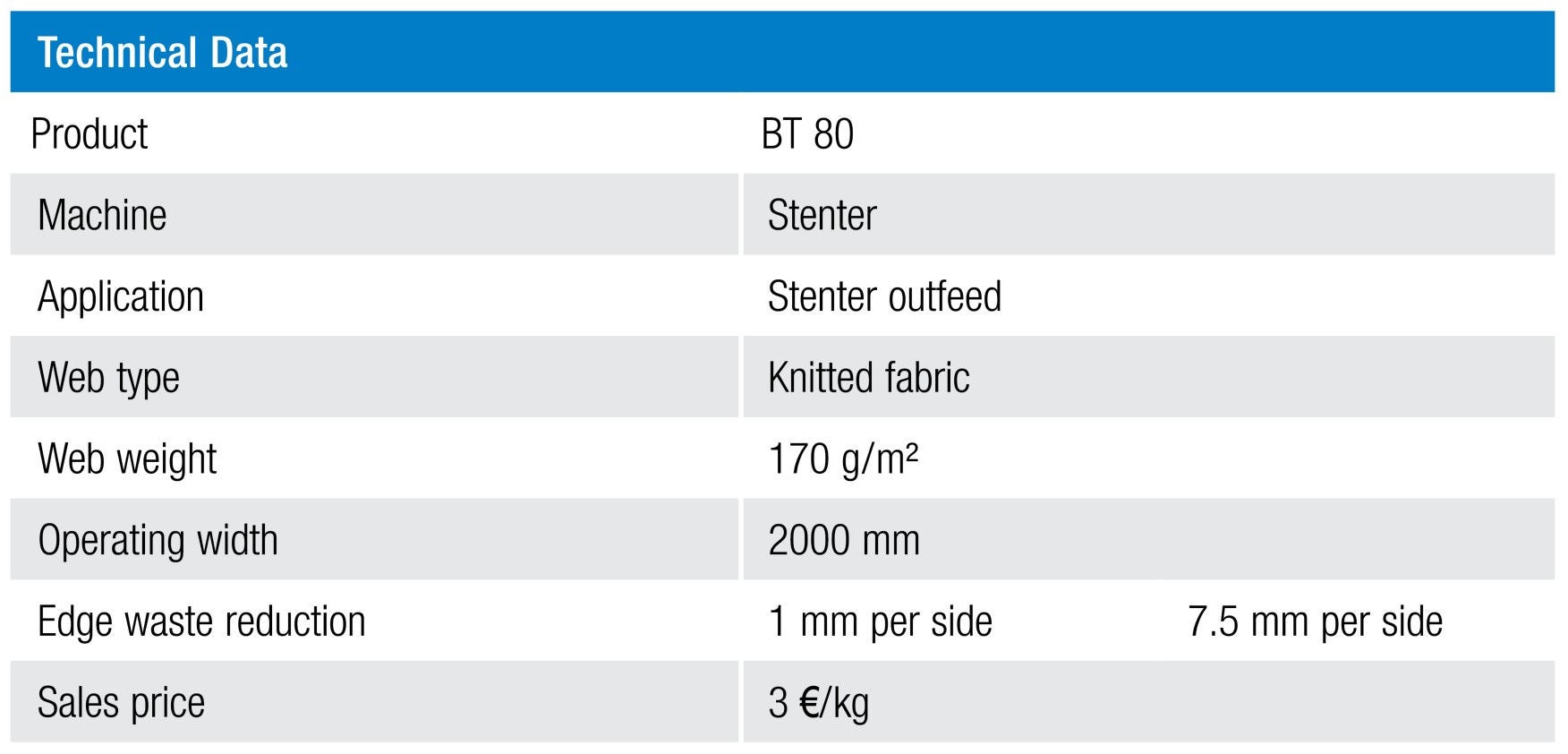

Such cutting devices usually can be found in stenters, compactors or sanforization systems. The following amortization calculation shows how the resulting savings accumulate:

Fig. 3: ROI calculation edge cut

Fig. 3: ROI calculation edge cut

This clearly demonstrates that a reduction of less than one centimeter per side with the specified parameters can already save over EUR 16,500 annually. After all, it is the little things that make the difference between an economically successful and a negligent company.

Exact edge trimming

Especially with digital printing, it is important not to let the weft threads protrude from the textile composite. The risk that a thread entrained by the print head will destroy not only the textile surface, but also the print head itself, is simply too great and the consequences too capital-intensive: a new print head costs five figures - the costs for downtime and repair are not even taken into account in that amount. No one can afford such a big production disaster today. Therefore, the highest level of accuracy is required in this case. This is where Erhardt+Leimer's AI steps in. The sensor camera precisely detects the outermost warp thread and, just as with minimal edge trimming, aligns the cutting blade accordingly. So far, the industry has only used an offset from the edge of the web to get as close as possible to the edge of the textile surface. In the production process, this means that only a safety margin is used. That might work out well - but it does not have to. In the best case, the safety margin cuts away too much, but in the worst case, it does not prevent a disaster. Neither result is satisfactory.

Over 60,000 data sets are now helping the AI to eliminate this margin of safety and to only perform the edge trimming that is actually necessary. On the one hand, this saves users more than a ton of otherwise lost goods per year and, on the other hand, it gives them the certainty that the print head is in the best hands possible with E+L's AI-based cutting technology. As a special bonus the free AI app is now available for everyone, enabling users to check which materials are already in the database.

Fig.4: AI sensor ELWARP and QR code for the apps (Apple & Android)

Center cut

It is often more efficient to represent continuous processes in a wide material web and then convert them into the desired use width after processing. This is where a center cut comes into play. In this production step, cutting blades are introduced into the web at the desired point and then continuously cut the final strips from the web. In order to ensure a defined cutting position during the entire production, a support table guides the flow of the web. Since accessibility is limited in the middle of the web, the circular blade also has an attached grinding unit for resharpening. The center cut is mainly used in the production of non-woven fabrics, but is also suitable for woven, pile and knitted fabrics as well as for imitation leather and foam material.

Fig. 5: Schematic representation of a center cut

Fig. 5: Schematic representation of a center cut

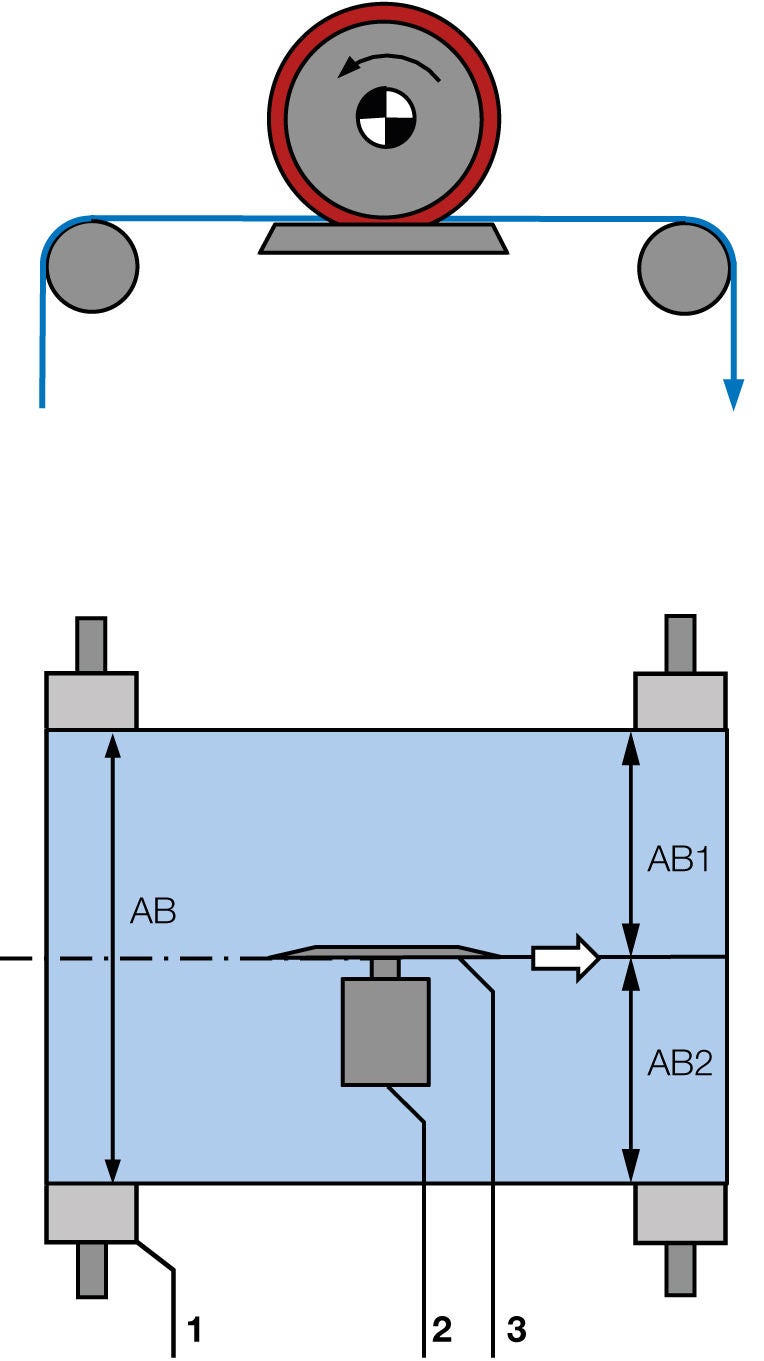

Tube slitting

Some textiles are not produced as sheet material, but are produced in a tube in order to be cut open during a later stage of the process for further treatment. Tubular fabrics are a good example of this. To securely and consistently represent the cutting process, these textiles have a "drop stitch" that serves as reference for the cutting process. A matrix sensor reliably detects its position in the transmitted light principle and controls a guide basket via a digital position controller, which brings the drop stitch exactly into the cutting area of the circular blade. All the machine operator has to do is to position the drop stitch under the sensor and the system learns the guidance criterion independently (Easy Teach mode). The tube is subsequently opened continuously and fully automatically.

Fig. 6: Cutting device on tube slitting system

Fig. 6: Cutting device on tube slitting system

Periphery

Along with selecting the right sensors and blades, it is crucial to direct the web in a controlled and consistent way to the cutting zone and remove the trim from the textile surface. Especially with knitwear, a fully unrolled web is a prerequisite for a satisfactory result. Depending on the existing product properties, either a motorized, a mechanical or even a pneumatic solution is suitable for this purpose. The edge trimming is extracted via a noise-dampened side channel compressor.

Summary

Even though the subject of cutting textile webs dates back a long time, it remains just as relevant today. Especially in the current performance structure, it is indispensable to optimize the small things in order to derive the greatest possible benefit from them. The possibilities that E+L showcases through the use of cutting-edge technologies like AI and customized components in the realm of web separation lead to unparalleled optimization and automation. This alone can save hundreds of tons of goods every year – with great effect on profitability and revenue.

The Bavarian family business Erhardt+Leimer is also innovating in the ordering process: To provide its customers with the ability to purchase the desired product 24/7 without language barriers, it offers a webshop that allows orders to be organized quickly and easily. If you would like to try it out: https://shop.erhardt-leimer.com

Frequently Asked Questions

Web cutting is the continuous separation of textile webs during or after finishing to create defined use widths, clean edges, or multiple partial webs.

AI-assisted systems optically detect real web edges based on the path of the outermost warp thread, enabling much more precise edge cuts than the traditional offset method. This reduces material waste, increases process reliability, and improves cut-edge quality.

Exact edge trimming is especially critical in digital printing. Protruding weft threads can snag on the print head and damage both the textile and the print head, leading to expensive repairs and downtime. An AI-assisted cutting system can help prevent this.

Center cuts are mainly used in nonwoven production, but they are also suitable for woven, knitted, and pile fabrics as well as imitation leather and foam materials.

The drop stitch serves as the reference line for tube slitting in tubular textiles. Using the transmitted light principle, a matrix sensor detects the drop-stitch line and guides the blade along it so the tube is opened fully automatically at the same position every time.

Peripheral equipment guides the textile into the cutting zone and out of it again. Depending on the product properties, motorized, mechanical, or pneumatic solutions can be used. Additionally devices such as a side channel compressor extract the separated edge trim.