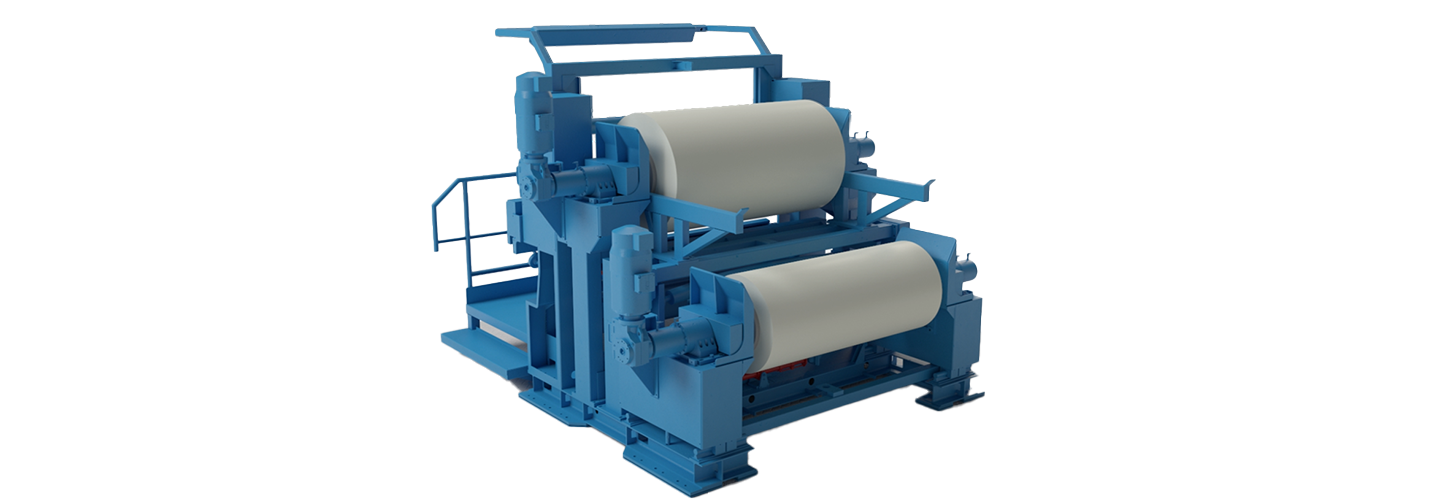

Rewinding machine to fix typical service liner problems in order to increase quality and productivity.

It is supplied with visualization of the damage and contamination. As an option, the customer can choose the automatic version.

Layout

- Let-off with pneumatic core chucks driven by a geared motor

- Automatic sewing device

- Inspection table

- Wind-up

- ELTENS Load cells

- E+L Sensor

- EL.MOTION Actuating drive

- ELWINDER Winding station

Rewinding machine detects and corrects the following problems

- Tear and hole presence

- Misalignment

- Defective edge

- Knot presence

- Fold presence

Application

- Fabric liner (Cretonne)

- Polythene foil

- Polyester

- Plastic film

- Others

Benefits

- Extended life of the liner

- Cost reduction in liner replacement

- Faster bobbins set up/changes

- Customized solutions based on customer needs and requirements

Functions

- Guiding

- Spreading

- Repairing (cutting and sewing) by removing damaged parts

- Tension control

- Manual or automatic damage inspection