- Description

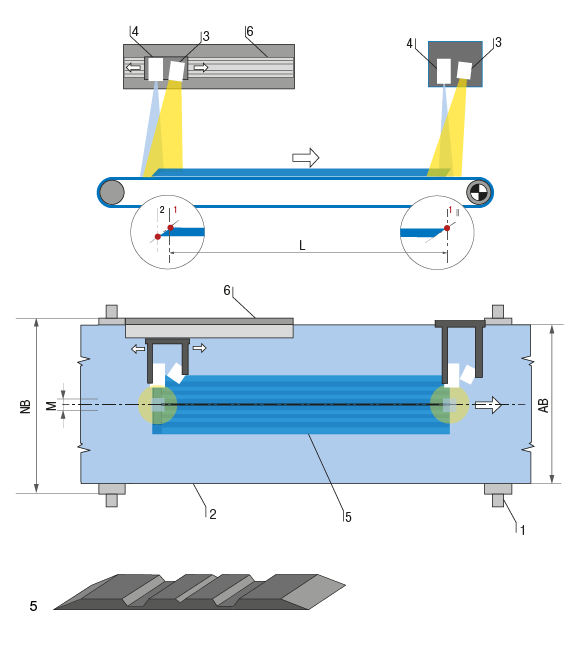

- Function drawing

Function

Two synchronized cameras acquire the ends of the cut product. The edges are detected in the image with the aid of a special algorithm. After prior calibration of the two cameras in relation to each other, the length measurement system can determine the final length of the tread measured.

Area of use

The length measurement system is used at the end of the extrusion line for quality documentation and for sorting out material that is out of tolerance.

Application

The tread length measurement system EL-Length is installed after the skiver. Due to material shrinkage, it is recommended that the measurements are taken as close as possible before the booking station. Only at this point has the tread almost reached its final length.

Legend

M = Measuring range | AB = Operating width (conveyor width) | NB = Nominal width | 1 = Guide roller | 2 = Conveyor belt | 3 = Light spot | 4 = Matrix camera | 5 = Tread | 6 = Side wall | L = tread length