- Description

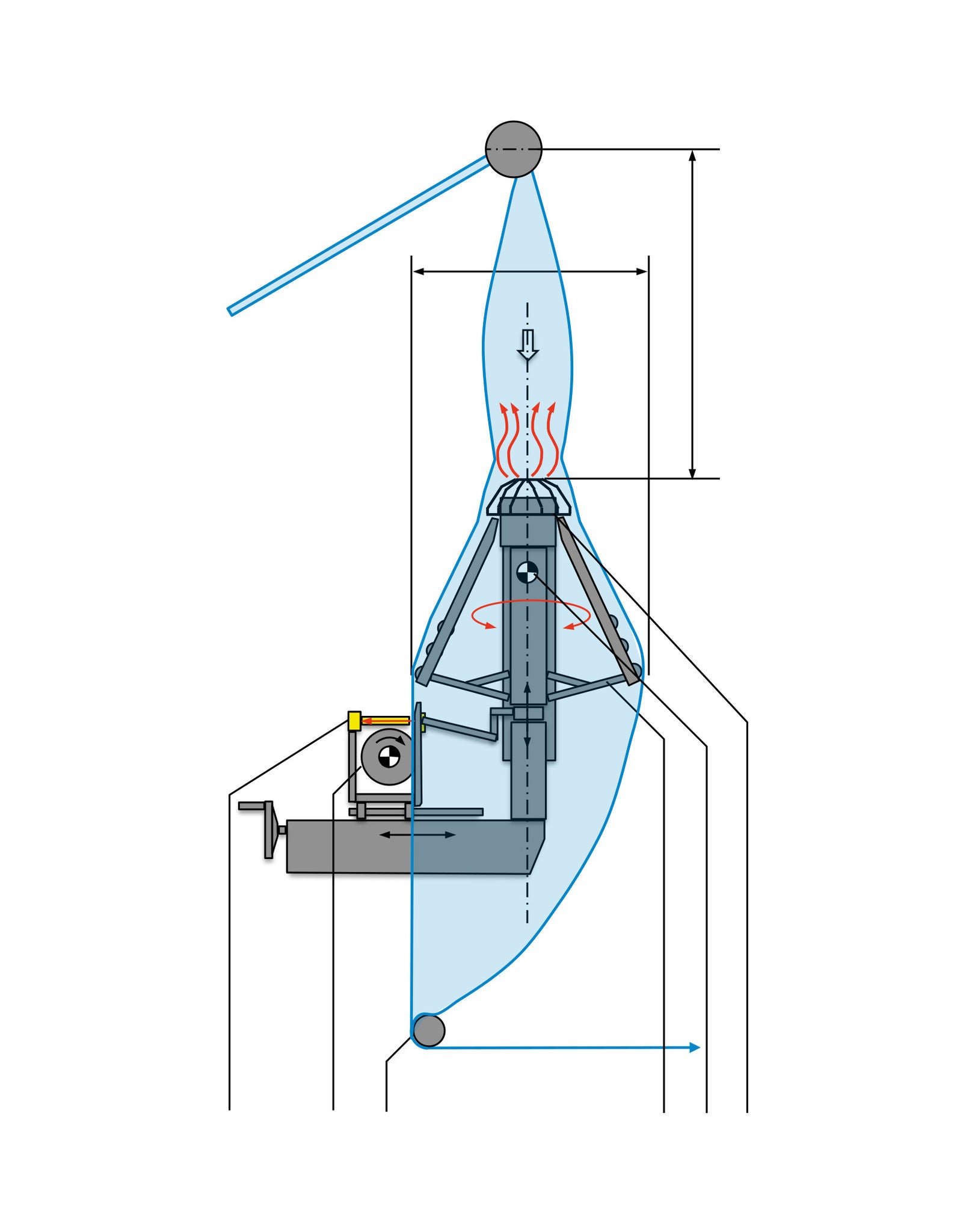

- Function drawing

Function

Textile tubular fabrics with a drop stitch must be cut exactly along a reference line. Using a drop stitch matrix sensor, this line is detected reliably using the transmitted light principle and fed to the position controller as the actual position. The digital position controller continuously compares the target and actual values and constantly controls the motorized, rotating guide basket. The guide basket can be adjusted to the desired tube diameter using a hand wheel. The tube-shaped knitted fabric is opened precisely in the drop stitch with cutting technology systems.

Area of use

In the textile finishing process, knitted fabrics produced in a tube must be cut open along the drop stitch for further processing. In so doing, the cutting technology systems allow an exact cut.

Application

Normally, the existing twist on a textile tube is untwisted and the tube is fed to the tube slitter from above. In so doing, the pre-entry path should be at least 3 m.

Legend

1 = Circular blade cutting | 2 = Actuating drive | 3 = Rotating guide basket | 4 = Sensor | 5 = Guide roller | 6 = Fan | D = Tube diameter | L1 = Infeed path