Automation & Vision Systems

- Description

- Technical Data

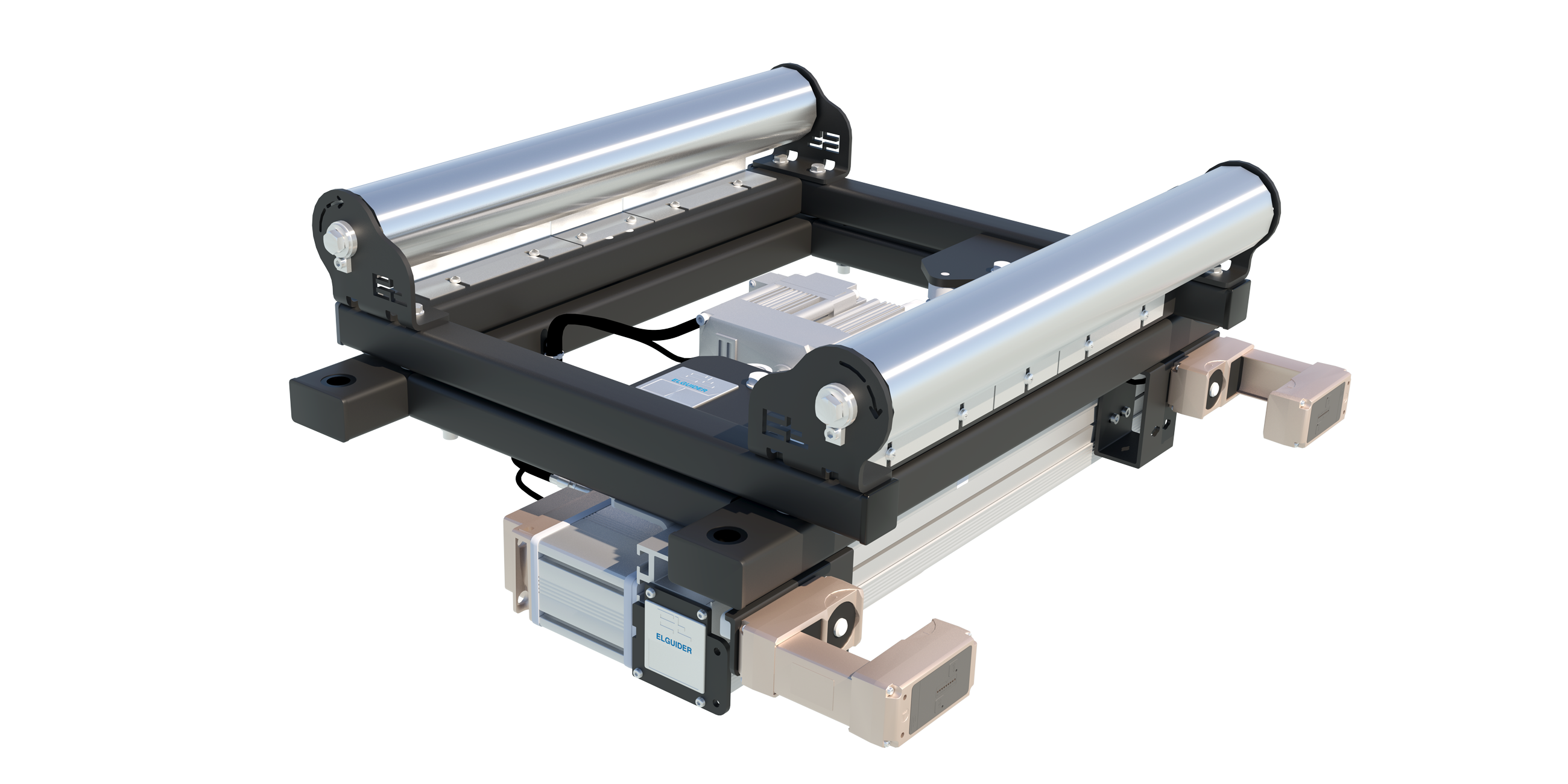

- Web guiding system in frame design with wear-free, brushless drive technology for a nominal width of 400 to 3,800 mm and a maximum web tension of 700 N

- Can be combined with various sensors

- FR 54 infrared edge sensor for nonwoven fabrics

- FX 41/53 ultrasonic edge sensor for paper and transparent plastic materials

- FE 53 color line sensor for printed webs with line or color contrasts

- FE 95 infrared wide band sensor for web center guiding

- Optionally with VS 80 motorized sensor positioning for fast format changes

- Can be networked via Ethernet with EL.NET control systems in a star or line topology

- Optionally with integrated fieldbus interface Ethernet IP, Ethernet UDP or Profinet

- Simple service and diagnostics options via web-based management tools based on a standard web browser

| Positional accuracy FR 54, FX 42, FX 52, FE 52, FR 61 | < ± 0.1 mm (material-dependent) |

| Error frequency | Max. 4 Hz |

| Nominal actuating travel | |

| TL 400 to 700 mm | Max. ±20 mm |

| TL 800 to 1100 mm | Max. ±30 mm |

| TL 1200 to 2000 mm | Max. ±55 mm |

| TL 2100 to 2500 mm | Max. ±80 mm |

| Nominal actuating speed at outfeed roller | 1 to 30 mm/s (AG 90, F=800 N) |

| Web tension | Max. 700 N |

| Roller diameter | 80/100/120/160 mm |

| Ambient temperature | +10 °C to +50 °C |

| Relative humidity | 15 to 95 % (non-condensing) |

| Operating voltage, nominal value | 24 V DC |

| Nominal range | 20 to 30 V DC (ripple included) |

| Nominal range with power supply | 100 to 240 V, 50/60 Hz |

| Current consumption | Max. 2.5 A DC (AG 90, manual sensor positioning) |

| Max. 3.7 A DC (AG 90, motorized sensor positioning) | |

| Max. 5.5 A DC (AG 91, manual sensor positioning) | |

| Max. 6.8 A DC (AG 91, motorized sensor positioning) | |

| Interface | Ethernet EL.NET protocol |

| Fieldbus interface | Ethernet UDP |

| Ethernet/IP | |

| Profinet | |

| Certifications | Declaration of incorporation according to Machinery Directive |

| 2006/42/EC | |

| NRTL certificate CU72180310 02 | |

| Protection class | IP 54 |