User-friendly data management for Industry 4.0 processes

Stadtbergen, February 15, 2023

Erhardt+Leimer at ICE Europe 2023

At ICE Europe 2023 Erhardt+Leimer will be presenting a new software tool designed to act as the central point for management of production data – for web guiding, web tension control and for measurement of the basis weight and the thickness of coatings. E+L specializes in automation and inspection technology and has an international sales and service network (booth 1110, hall A5).

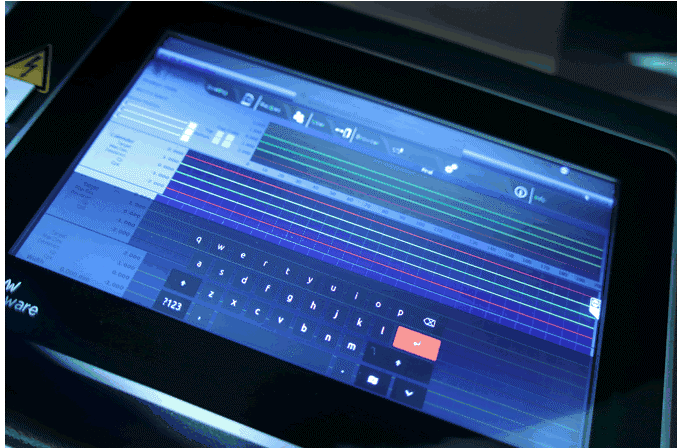

Data management software ELQ

This is where all of your production data comes together – the central software ELQ enables you to control and optimize all E+L systems and to manage all production data – including data from third-party systems – via standard interfaces.

Thanks to the modular approach of the software, a large number of systems and individual sensors can be connected, e.g. web guiding systems based on the latest EL.NET technology, web tension measuring systems, and measuring systems for thickness and basis weight. All the data is presented via a dashboard for maximum user friendliness. ELQ provides functions for statistical analyses, automatic order and roll reports, central recipe management, and operation and optimization of the connected systems. The range of available customer interfaces includes Ethernet IP/UDP, Profinet, SQL, and OPC-UA.

Industry 4.0-capable sensors and drives

EL.NET sensors and linear/rotary drives will once again play a prominent role at this year's E+L booth. EL.NET technology optimizes production processes on the basis of a digital, web-based system architecture with network capability and IoT support.

In an EL.NET control system, digital E+L components connect together to form a network that can be quickly and easily integrated into the customer's network. EL.NET also enables simple integration of any third-party sensors the customer is using. All devices automatically and selectively exchange the relevant data required to optimize control within a production plant.

With EL.NET you can connect up to 255 control systems together in a network. Here, automation of the processes depends to a large degree on the data acquired at all levels of the production process. This data delivers a high level of transparency and makes it possible to monitor and optimize processes in real time – and therefore to minimize downtimes and scrap.

Every EL.NET device is equipped with an integrated web server, which is used to exchange the data. This feature makes for a user-friendly, guided commissioning process and enables optimization and maintenance via web-based management, i.e. using a standard web browser, with no need for special software. The EL.NET components also include digital edge and color line sensors, controllers, and brushless – and therefore wear-free – actuating drives. PoE is the simple solution used for wiring and power supply to the devices. With its "plug & play" philosophy, the system is also incredibly quick and easy to set up.

The components flexibly adapt to new requirements and keep retooling times to a minimum to guarantee efficient production. Integrated fieldbus interfaces and optional fieldbus modules make it easier to connect E+L control systems to the customer's control or data management systems.

Rotary drives with integrated controller

The brushless motors of type AD 11 and AD 12 marketed under the EL.MOTION brand are "intelligent" drives with an integrated controller. The drives can be used for position control, speed control, or torque control and are particularly suitable for applications where very quiet operation and long service life are key. Two external limit switches can be connected directly to the drive.

The combination of distributed intelligence with a dedicated interface concept allows a decentralized drive topology to be implemented that greatly reduces wiring and space requirements in the control cabinet.

Erhardt+Leimer has a wide range of communication standards on offer for these drives. The AD series comes with EL.NET technology, which allows control tasks to be implemented without any need whatsoever for an external controller. E+L has a large number of sensors and input/output modules available for this. All the drives come with web-based management on board as standard. This means that, when the motor is connected via Ethernet, it can be addressed from the browser of a PC, allowing you to check and adjust settings or query the current status. But that is not all: E+L also places great value on open connectivity and therefore also offers open access via Ethernet/UDP or certified standard protocols, such as Ethernet/IP, Profinet, and Powerlink.

In addition, at ICE 2023 E+L will also be presenting its ultrasonic system ELTIM for measurement of basis weight and coating thickness, the pivoting frame ELGUIDER DRB33 with motorized sensor positioning VS 80, as well as various components for web tension measurement and control.